Preparation method and application for bombax ceiba peel-based porous biomass carbon material

A technology of biomass charcoal and fruit peel, which is applied in the direction of carbon preparation/purification, hybrid capacitor electrodes, etc., can solve the problems of no electrode material found, less adsorption performance, etc., and achieve suitable for large-scale production, green and environmentally friendly price, simple and easy process line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Put 2 g of pretreated kapok peel powder into a 20 mL crucible, place it in a resistance furnace, and heat it at 5 °C min -1 The temperature was raised at a rate of 300 °C, and anaerobic pyrolysis was carried out at this temperature. After the holding time was 2 hours, it was cooled to room temperature, and the product was dissolved in 1 mol L -1 Soak in hydrochloric acid for 0.5 hour, wash to neutrality, dry and grind to obtain pre-carbonized product.

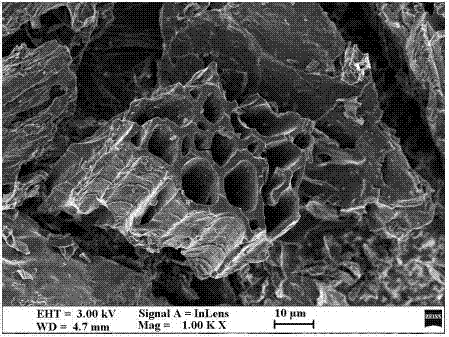

[0030] (2) Put 2 g of the pre-carbonized product into a 20 mL graphite crucible, place it in a resistance furnace, and heat it at 5 °C min -1 The temperature was raised to 700 °C at a certain rate, and carbonized at this temperature under the protection of nitrogen. The holding time was 2 hours. -1 Soak in hydrochloric acid for 0.5 hours, wash to neutrality, and dry to constant weight to obtain a kapok peel-based porous biochar material. Its SEM picture is as figure 1 As shown, it can be seen from the picture that...

Embodiment 2

[0032] (1) Put 2 g of pretreated kapok peel powder into a 20 mL crucible, place it in a resistance furnace, and heat it at 4 °C min -1 The temperature was raised at a rate of 500 °C, and anaerobic pyrolysis was carried out at this temperature. After the holding time was 1 hour, it was cooled to room temperature, and the product was dissolved in 1 mol L -1 Soak in hydrochloric acid for 0.5 hour, wash to neutrality, dry and grind to obtain pre-carbonized product.

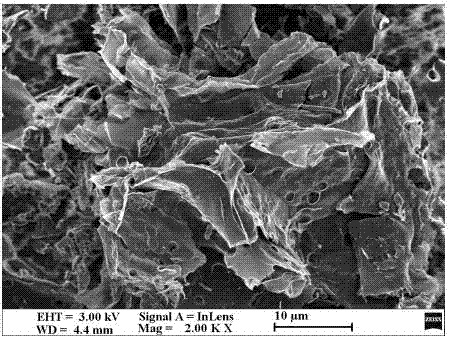

[0033] (2) Put 3 g of the pre-carbonized product into a 20 mL graphite crucible, place it in a resistance furnace, and heat it at 4 °C min -1 The temperature was raised to 900 ℃ at a certain rate, and carbonized at this temperature under the protection of nitrogen. The holding time was 1 hour. -1 Soak in hydrochloric acid for 0.5 hours, wash to neutrality, and dry to constant weight to obtain a kapok peel-based porous biochar material. Its SEM picture is as figure 2 As shown, it can be seen from the picture that t...

Embodiment 3

[0035] (1) Put 2 g of pretreated kapok peel powder into a 20 mL crucible, place it in a resistance furnace, and heat it at 8 °C min -1 The temperature was raised to 400 °C at a high rate, and anaerobic pyrolysis was carried out at this temperature. After the holding time was 0.5 hours, it was cooled to room temperature, and the product was dissolved in 1 mol L -1 Soak in hydrochloric acid for 0.5 hour, wash to neutrality, dry and grind to obtain pre-carbonized product.

[0036] (2) Put 3 g of the pre-carbonized product into a 20 mL graphite crucible, place it in a resistance furnace, and heat it at 4 °C min -1 The temperature was raised to 1000 °C at a rate of 1000 °C, and carbonized at this temperature under the protection of nitrogen. The holding time was 2 hours. After fully carbonized under normal pressure, it was cooled to room temperature with the furnace. -1 Soak in hydrochloric acid for 0.5 hours, wash to neutrality, and dry to constant weight to obtain a kapok peel-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com