Method for making high activity dietary fibers from bamboo shoot scraps

A technology of dietary fiber and leftovers, which is applied in the field of preparation of highly active bamboo shoot dietary fiber, can solve environmental problems such as pollution and waste of materials, and achieve the effects of safe operation, low investment in equipment, and suitability for industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

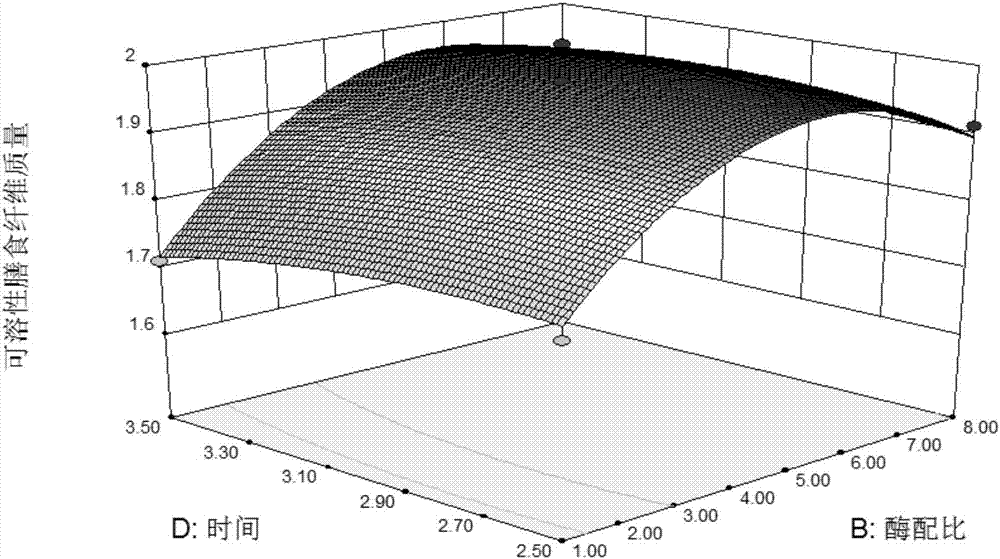

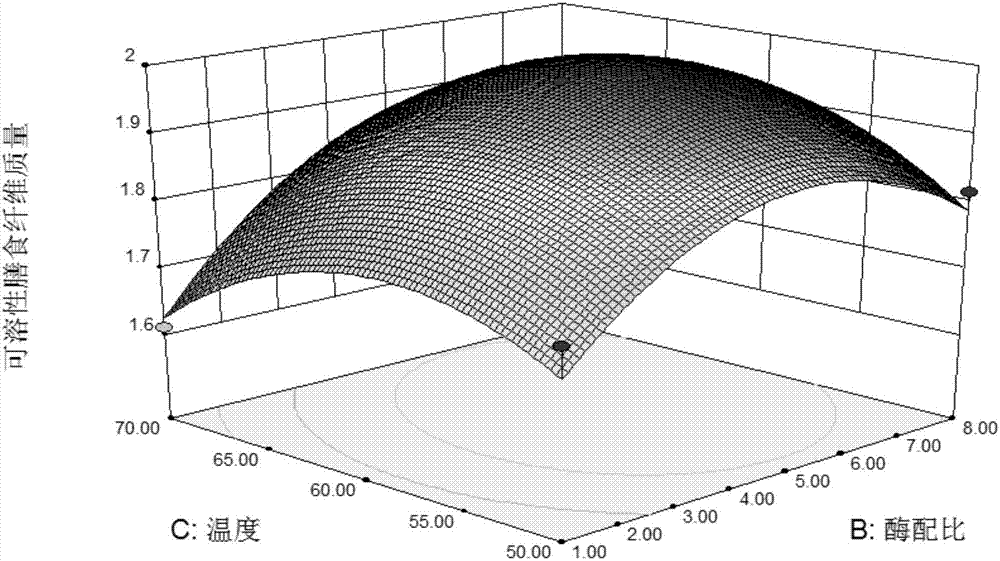

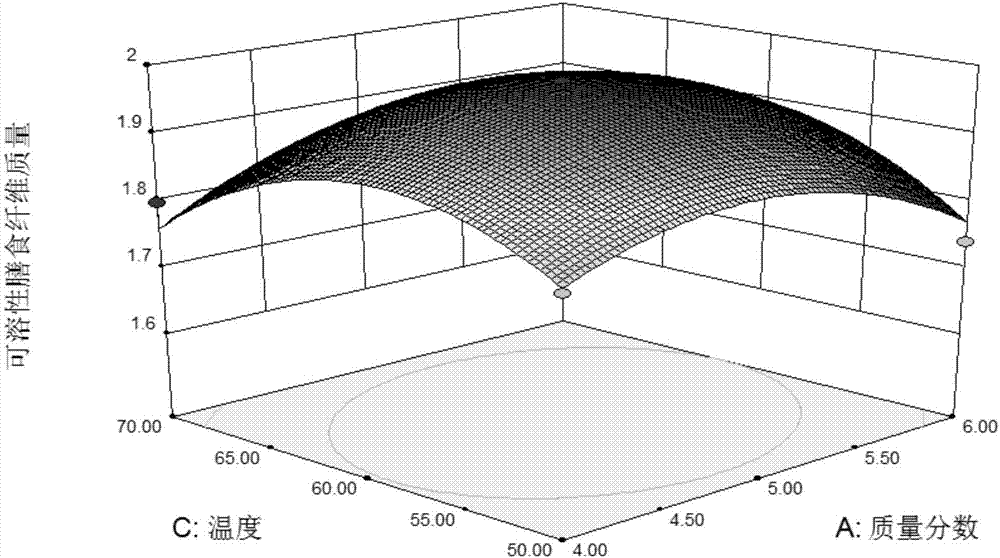

[0027] Experimental example 1. Response surface experiment

[0028] (1) Put the leftovers of bamboo shoots into a tissue grinder, and dry the crushed bamboo shoot residues in an oven at 45°C until the moisture content is below 6%. After drying, pulverize with pulverizer, cross 40 mesh sieves to obtain bamboo shoot powder for subsequent use.

[0029] (2) Accurately weigh 20g of bamboo shoot powder, dissolve the bamboo shoot powder in water at a solid-to-liquid ratio (g / mL) of 1:30, and disperse using a high-shear dispersing emulsifier at 15000r / min for 10min.

[0030] (3) Add a certain amount of cellulase and xylanase to the mixed solution described in step (2) according to the conditions described in Table 1, and place it in a shaking water bath at 60° C. for a period of time. After enzymatic hydrolysis, add 4 times the volume of ethanol to the supernatant obtained by centrifugation, let it stand at room temperature, filter under reduced pressure, transfer the remaining filte...

experiment example 2

[0040] Experimental Example 2, Determination of Dietary Fiber Properties after Composite Enzyme Modification

[0041] ① Determination of water holding capacity (WRC):

[0042] Accurately weigh 0.5g of dietary fiber sample and record it as W 1 , mixed with 20mL distilled water and added to a 50mL centrifuge tube, oscillated evenly, then placed at room temperature for 24h, centrifuged at 4000r / min for 10min, discarded the supernatant, blotted the residual water on the filter paper and weighed it, recorded as W 2 , and finally dried at 105°C to a constant weight, accurately weighed and recorded as W 3 , the calculation formula of water holding capacity:

[0043]

[0044] ② Determination of oil holding capacity (OBC):

[0045] Weigh 1.0g dietary fiber sample and record it as W 1 , put it in a 50mL centrifuge tube, add 20mL of edible corn oil into it, soak at 37°C for 1 hour, stir once every 10 minutes, then centrifuge at 4000r / min for 15 minutes, discard the oil and other s...

experiment example 3

[0058] Experimental example 3, the effect of compound enzyme modification on the properties of bamboo shoot dietary fiber

[0059] Table 4 Functional properties of bamboo shoot dietary fiber under different treatments

[0060]

[0061]

[0062] It can be seen from Table 4 that after adding compound enzyme treatment, the water holding capacity, oil holding capacity, swelling capacity, glucose adsorption capacity and NO 2 - The physical and chemical properties of adsorption capacity are better than those of dietary fiber before modification. The water holding capacity increased from 4.86g / g to 9.03g / g, 1.86 times that before modification, the oil holding capacity increased from 3.36g / g to 7.44g / g, 2.21 times that before modification, and the swelling power was 3.42 g / mL increased to 8.46g / mL, which was 2.47 times that before modification, the glucose adsorption capacity increased from 10.12mmol / g to 18.18mmol / g, which was 1.80 times that before modification, and the nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com