A kind of sleep aid natural rubber latex pillow core and preparation method thereof

A natural rubber latex and sleep aid technology, applied in sleep or relaxation devices, pillows, etc., can solve the problems of damage to Chinese herbal medicine components, short duration of drug effects, etc., to achieve emotional balance, change the state of qi and blood, and high elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

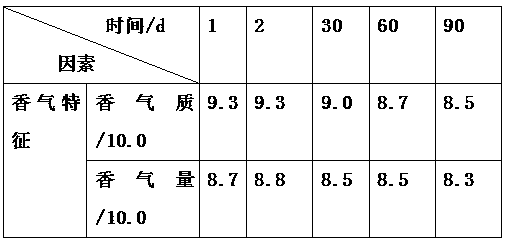

Image

Examples

Embodiment 1

[0028] The amount of raw materials by weight is as follows: natural latex 100, agarwood essential oil microcapsules 10, wherein agarwood essential oil 3, 50% zinc oxide dispersion 2, 50% sodium fluorosilicate dispersion 0.5.

[0029] The wall material of the agarwood essential oil microcapsules is gelatin and gum arabic with a mass ratio of 1:1.

[0030] The preparation process is as follows:

[0031] (1) Dissolving agarwood essential oil in the wall material of microcapsules, emulsifying, agglomerating, solidifying, and spray drying to obtain microcapsules;

[0032] When emulsifying, first fully dissolve the wall material of the capsule with water at 40°C, then add agarwood essential oil, rotate in a high-speed disperser at 10,000 rpm, and emulsify for 3 minutes to obtain an emulsion;

[0033] When coagulating, the emulsion is diluted to 80% with water, heated to 30°C, and 10% acetic acid solution is added until coagulation occurs;

[0034] When curing, adjust the pH to 6.0...

Embodiment 2

[0038] The amount of raw materials in parts by weight is as follows: natural latex 100, agarwood essential oil microcapsules 5, wherein agarwood essential oil 4, 50% zinc oxide dispersion 2, 50% sodium fluorosilicate dispersion 0.5.

[0039] The wall material of the agarwood essential oil microcapsules is gelatin and gum arabic with a mass ratio of 1:1.

[0040] The preparation process is as follows:

[0041] (1) Dissolving agarwood essential oil in the wall material of microcapsules, emulsifying, agglomerating, solidifying, and spray drying to obtain microcapsules.

[0042] When emulsifying, first fully dissolve the wall material of the microcapsules and water at 60°C, then add agarwood essential oil, rotate in a high-speed disperser at 9000 rpm, and emulsify for 5 minutes to obtain an emulsion;

[0043] When coagulating, the emulsion is diluted to 60% with water, heated to 50°C, and 10% acetic acid solution is added until coagulation occurs;

[0044] When curing, adjust th...

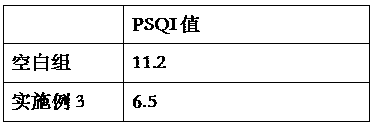

Embodiment 3

[0048] The amount of raw materials in parts by weight is as follows: natural rubber latex 100, agarwood essential oil microcapsules 15, wherein agarwood essential oil 1, 50% zinc oxide dispersion 2, 50% sodium fluorosilicate dispersion 0.5.

[0049] The wall material of agarwood essential oil microcapsules is gum arabic and maltodextrin with a mass ratio of 7:3.

[0050] The preparation process is as follows:

[0051](1) Dissolving agarwood essential oil in the wall material of microcapsules, emulsifying, agglomerating, solidifying, and spray drying to obtain microcapsules.

[0052] When emulsifying, first fully dissolve with water at 50°C, then add agarwood essential oil, rotate in a high-speed disperser at 95,000 rpm, and emulsify for 4 minutes to obtain an emulsion;

[0053] When coagulating, the emulsion is diluted to 70% with water, heated to 40°C, and 10% acetic acid solution is added until coagulation occurs;

[0054] When curing, adjust the pH to 5.5 with 10% sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com