Cerium-based composite oxide VOCs (volatile organic compounds) combustion catalyst using metal organic framework as template and preparation method thereof

A metal-organic framework, composite oxide technology, applied in catalyst activation/preparation, combustion method, physical/chemical process catalyst, etc., can solve the problems of long reaction time, large energy consumption, complex process, etc., and achieve good catalytic performance, The effect of improved catalytic ability and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

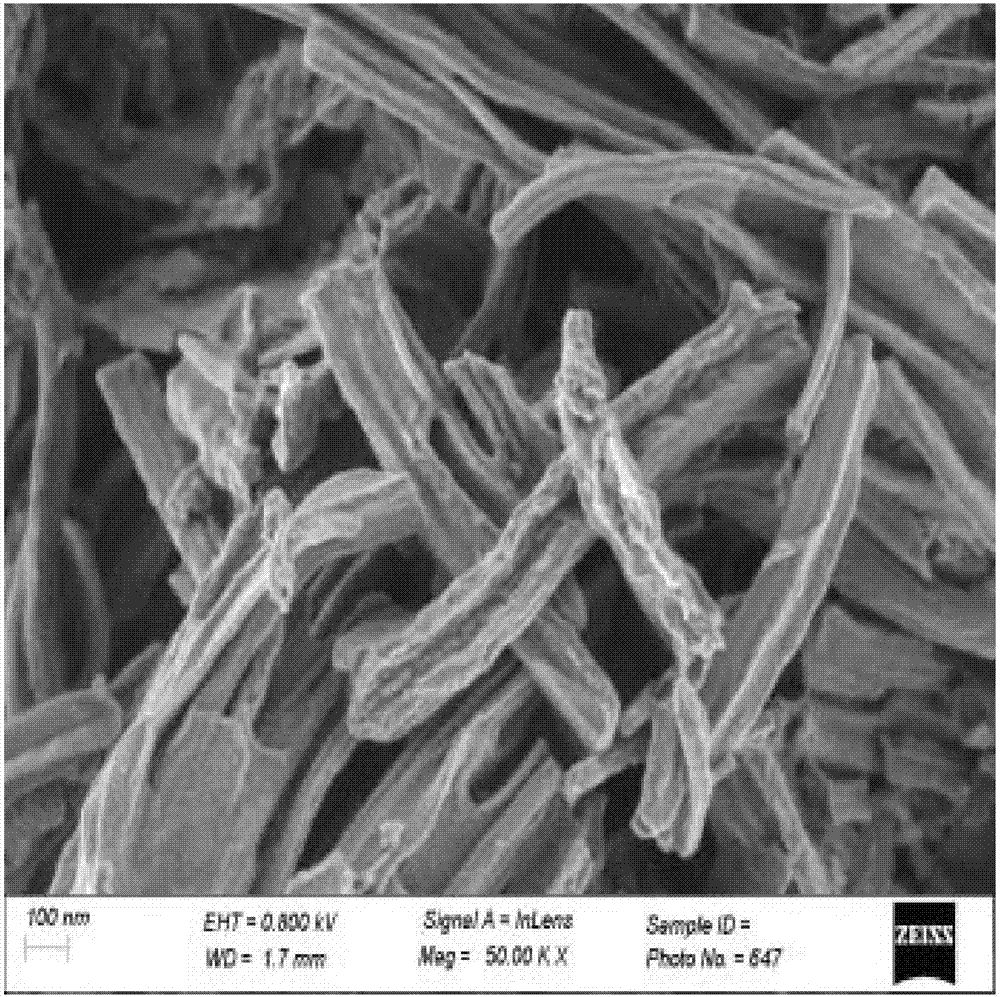

[0040] In the specific embodiment of the present invention, the cerium-based metal-organic framework material used is Ce-BTC (molecular formula is Ce(1,3,5-BTC)(H 2 O) 6 ); The preparation method of Ce-BTC comprises the following steps:

[0041] Take a cerium-based salt and an organic ligand (mesitylene), and configure a metal-organic framework compound Ce(1, 3, 5-BTC)(H2 O) 6 Precursor mixed liquid, let stand, wash with solvent after centrifugation, dry after filtering, grind, obtain powdery sample Ce(1,3,5-BTC)(H 2 O) 6 .

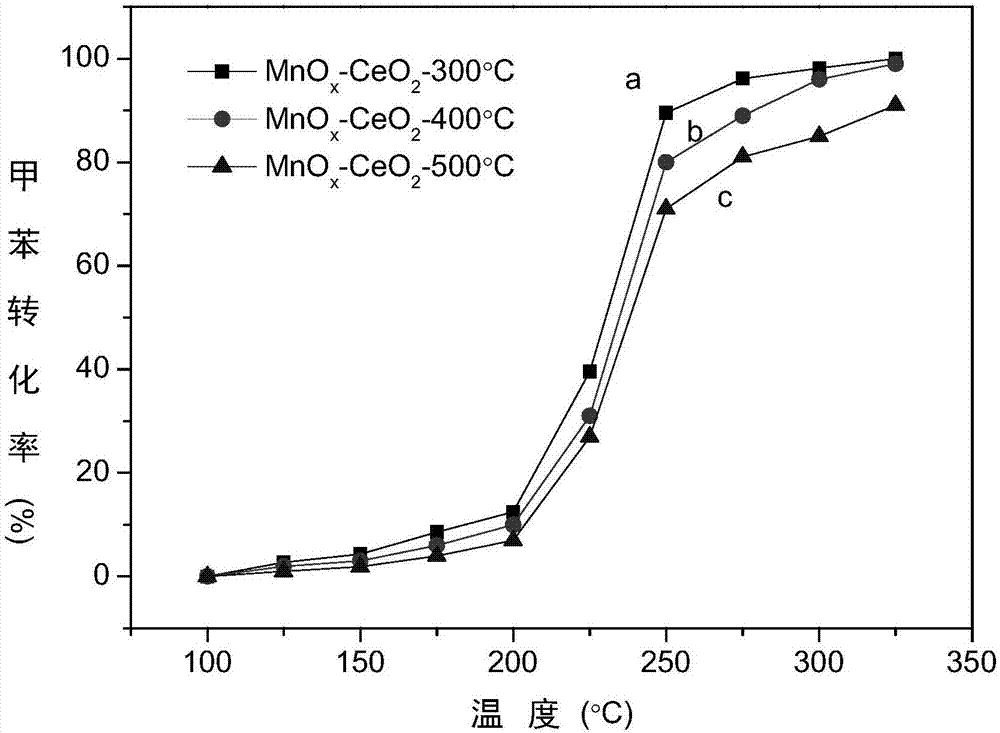

[0042] In a specific embodiment, for the decomposition temperature range of the cerium-based metal-organic framework material Ce-BTC is between 300°C and 500°C, the calcination temperature is selected to be between 300°C and 500°C, the calcination time is 6 hours, and the calcination rate is 2°C / min .

Embodiment 1

[0044] MnOx-CeO 2 The preparation of composite catalyst, concrete steps are as follows:

[0045] (1) Weigh 4.34 g Ce(NO 3 ) 3 •6H 2 O was dissolved in 50 mL of deionized water, 2.10 g of mesitylene was dissolved in a mixture of 150 mL of deionized water and 200 mL of ethanol, and the above two solutions were mixed to obtain a precursor solution. Washed three times with deionized water, filtered and dried to obtain Ce(1, 3, 5-BTC)(H 2 O) 6 , was determined to be Ce(1, 3, 5-BTC)(H 2 O) 6 ;

[0046] The obtained Ce(1, 3, 5-BTC)(H 2 O) 6 The specific surface area is 715 m 2 / g;

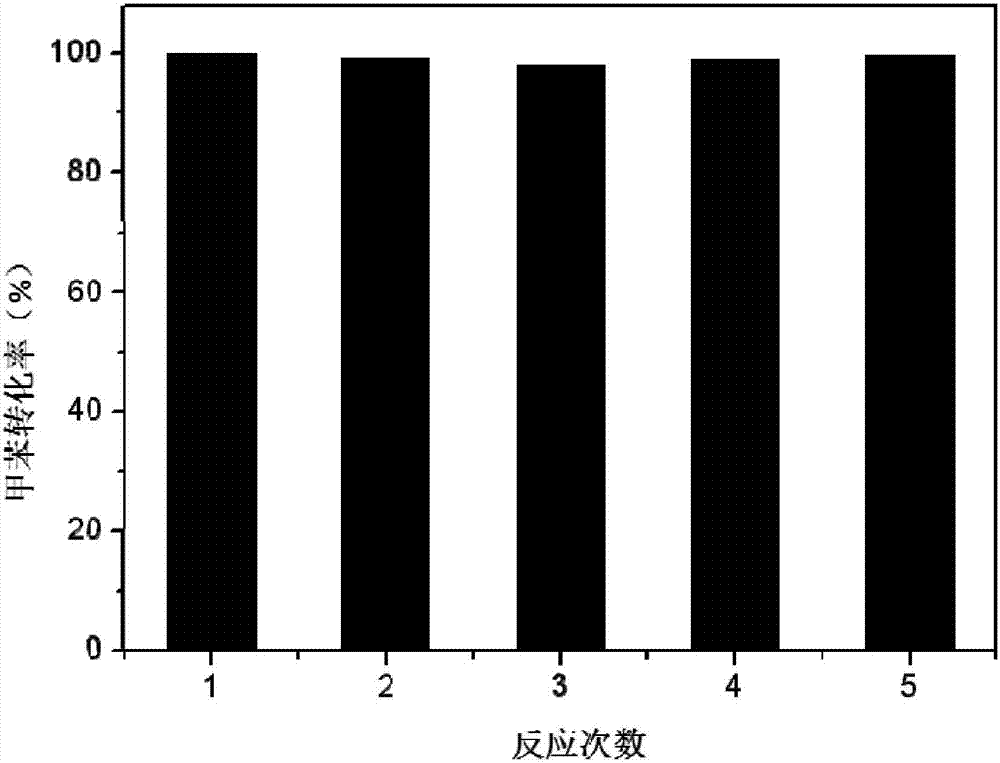

[0047] (2) Weigh 0.8 g Ce(1, 3, 5-BTC)(H 2 O) 6 and 182μL 50wt% Mn(NO 3 ) 2 The solution was dispersed in a mixed solution of 20 mL of ethanol and water (ethanol: water = 1:1, v / v), allowed to stand at room temperature for 24 h, dried at 60°C, and powdered after grinding, then dried at 300°C Calcined at 2°C / min for 6 h to obtain MnOx-CeO 2 composite catalyst material.

[0048] The prepar...

Embodiment 2

[0051] MnOx-CeO 2 The preparation of composite catalyst, concrete steps are as follows:

[0052] (1) Weigh 4.34 g Ce(NO 3 ) 3 •6H 2 O was dissolved in 50 mL of deionized water, and 2.10 g of mesitylene was dissolved in a mixture of 150 mL of deionized water and 200 mL of ethanol, and the above two solutions were mixed to obtain a mixed solution of precursor, which was left to stand for 24 h, and then used after centrifugation. Washed 3 times with deionized water, filtered and dried to obtain Ce(1, 3, 5-BTC)(H 2 O) 6 , was determined to be Ce(1, 3, 5-BTC)(H 2 O) 6 ;

[0053] The obtained Ce(1, 3, 5-BTC)(H 2 O) 6 The specific surface area is 715 m 2 / g;

[0054] (2) Weigh 0.8 g Ce(1, 3, 5-BTC)(H 2 O) 6 and 182μL 50wt% Mn(NO 3 ) 2 The solution was dispersed in a mixed solution of 20 mL of ethanol and water (ethanol: water = 1:1, v / v), and after standing at room temperature for 24 h, it was dried and ground at 60°C to obtain a powder, and then dried at 400°C to Cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com