A kind of preparation method of ceria modified montmorillonite supported ruthenium catalyst

A ceria, ruthenium catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of high price and high cost, and achieve production costs. Low cost, low cost and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

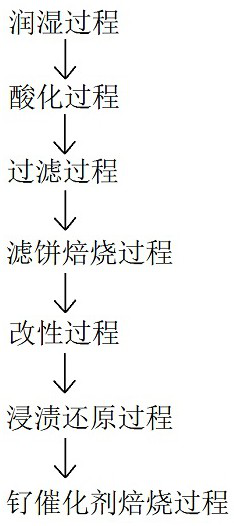

[0027] Embodiment 1: as figure 1 The preparation method of a kind of ceria modified montmorillonite supported ruthenium catalyst shown, comprises wetting process, acidification process, washing process, roasting process, modification process, dipping reduction process, ruthenium catalyst roasting process; First, take Add 500 grams of 1500-mesh montmorillonite raw material to 5000 grams of deionized water, stir for 30 minutes, and precipitate to remove the upper liquid and impurities; add the wetted montmorillonite to sulfuric acid with a concentration of 0.5 mol / L During heating, the temperature is controlled at 40°C, stirred, and acidified, and the acidification time is set to 3 hours; then the acidified montmorillonite is filtered, and the montmorillonite is washed with deionized water until it is neutral; the washed montmorillonite is The soil was dried at 110°C for 12 hours, and then the dried montmorillonite was pressed into a sheet shape with a diameter of 12 mm and a th...

Embodiment 2

[0035] Embodiment 2: as figure 1A kind of preparation method of shown a kind of ceria modified montmorillonite supported ruthenium catalyst, at first, get 500 grams of montmorillonite raw material of 1500 meshes, join in the deionized water of 5000 grams, stir after 30 minutes, precipitate, remove upper layer liquid and impurities; add the wetted montmorillonite into the hydrochloric acid with a concentration of 1 mol / L, heat, the temperature is controlled at 80°C, stir, and acidify, and the acidification time is set to 4 hours; then the acidified Filter the montmorillonite, wash the montmorillonite with deionized water until neutral; dry the washed montmorillonite at 110°C for 12 hours, then press the dried montmorillonite into a sheet , the lamellar diameter is 10 mm, and the thickness is 2 mm, and then the lamellar montmorillonite is fired at 500 ° C for 3 hours to set the shape.

[0036] Immerse the above-mentioned calcined and shaped sheet-like montmorillonite in an aque...

Embodiment 3

[0037] Embodiment 3: as figure 1 A kind of preparation method of shown a kind of ceria modified montmorillonite supported ruthenium catalyst, at first, get 500 grams of montmorillonite raw material of 1500 meshes, join in the deionized water of 5000 grams, stir after 30 minutes, precipitate, remove upper layer liquid and impurities; the wetted montmorillonite was added to nitric acid with a concentration of 5 mol / L, heated, the temperature was controlled at 70°C, stirred, and acidified, and the acidification time was set to 7 hours; then the acidified Filter the montmorillonite, wash the montmorillonite with deionized water to neutrality; dry the washed montmorillonite at 110°C for 12 hours, and then press the dried montmorillonite filter cake into tablets Layered, the diameter of the sheet is 12 mm, the thickness is 2 mm, and then the layered montmorillonite is fired at 600 ° C for 7 hours to set the shape.

[0038] Immerse the above-mentioned calcined and shaped lamella mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com