Bio-based flame-retardant modified asphalt and preparation method thereof

A modified asphalt, bio-based technology, applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of smoke and toxic gases, thermodynamic instability, poor ventilation conditions, etc., to improve safety and save energy Energy consumption, the effect of solving energy shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

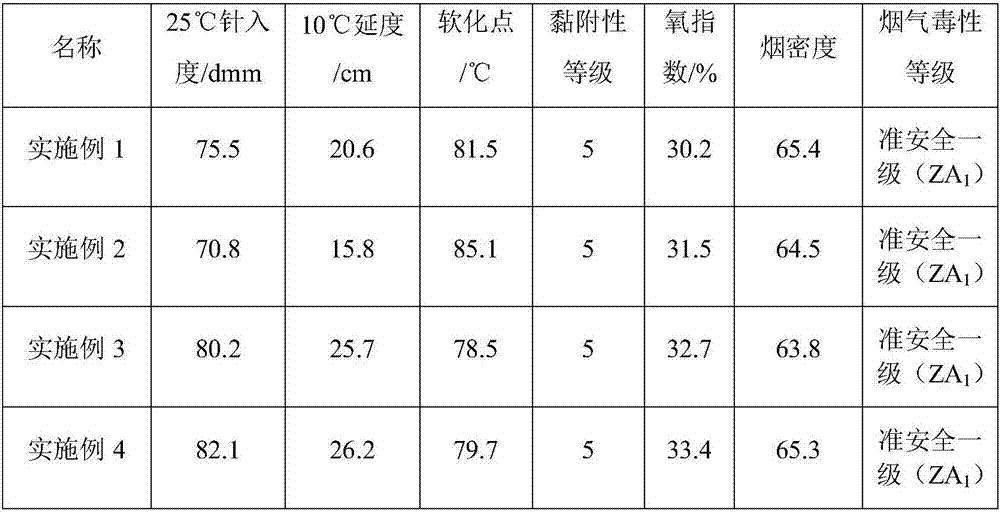

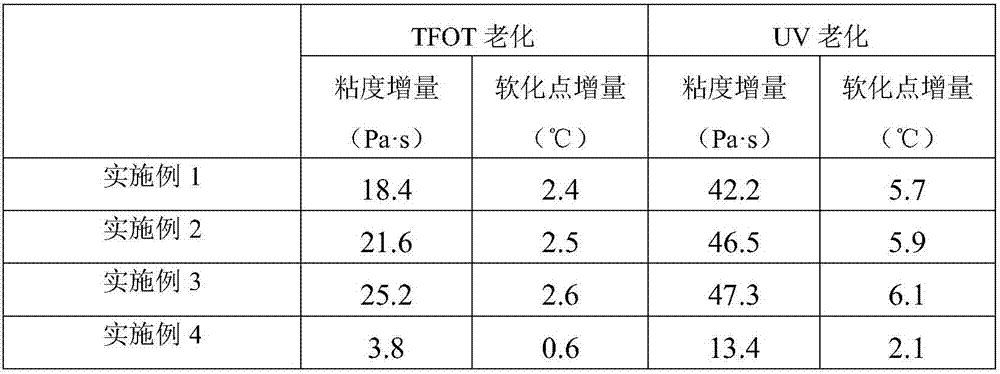

Examples

Embodiment 1

[0031] Heat 100 parts of No. 30 hard asphalt at 140-180°C to a fluid state, add 3 parts of Fischer-Tropsch wax into the hard asphalt and shear and stir for 10-30 minutes to obtain warm mixed hard asphalt, add 2 parts of sebacic acid di Add octyl ester to warm hard asphalt and mix well, then add 2 parts of Ca-Zn stabilizer, mix well to get the first mixture; add 2.5 parts of L(+)-tartaric acid to 30 parts of modified plant asphalt Mix the materials uniformly to obtain the second mixture; stir or shear the first mixture and the second mixture for 10-30 minutes at 120-160°C, mix well, and then add 5 parts of microcapsule flame retardant to obtain bio-based flame retardant modified asphalt.

[0032] Preparation of modified plant asphalt: first flash plant asphalt to pre-remove water and small molecule volatiles; use silica sol and zirconium oxychloride as raw materials to synthesize Zr-Si with ZSM-5 structure by hydrothermal method Molecular sieve, then treat the molecular sieve ...

Embodiment 2

[0034] Heat 100 parts of No. 20 hard asphalt at 140-180°C to a fluid state, add 2.5 parts of Sasobit into the hard asphalt and shear and stir for 10-30 minutes to obtain warm mixed hard asphalt, add 3 parts of epoxy octyl oleate Add 2.5 parts of phosphoric acid ester to the warm hard asphalt and mix evenly to obtain the first mixture; add 1.5 parts of L(+)-tartaric acid and 1 part of 2-hydroxyl-4-n-dodecyloxy Add benzophenone to 25 parts of modified plant asphalt and mix the materials uniformly to obtain the second mixture; stir or shear the first mixture and the second mixture for 10-30min at 120-160°C, mix uniformly, and then mix 8 Parts of microcapsule flame retardant was added to obtain bio-based flame retardant modified asphalt.

[0035] Preparation of modified plant asphalt: first flash plant asphalt to pre-remove water and small molecule volatiles; use silica sol and zirconium oxychloride as raw materials to synthesize Zr-Si with ZSM-5 structure by hydrothermal method ...

Embodiment 3

[0037] Heat 100 parts of No. 30 hard asphalt at 140-180°C to a fluid state, add 3 parts of palm wax to the hard asphalt and shear and stir for 10-30 minutes to obtain warm mixed hard asphalt, add 3 parts of acetyl citrate tributyl Add ester to warm hard asphalt and mix evenly, then add 3 parts of phosphate ester, mix well to get the first mixture; add 2.5 parts of (+)-bisabolactone A to 40 parts of modified plant asphalt and mix The material is uniform to obtain the second mixture; the first mixture and the second mixture are stirred or sheared for 10-30min at 120-160°C, and mixed evenly, and then 10 parts of microcapsule flame retardant are added to obtain a bio-based flame retardant improvement. Sexual asphalt.

[0038] Preparation of modified plant asphalt: first flash plant asphalt to pre-remove water and small molecule volatiles; use silica sol and zirconium oxychloride as raw materials to synthesize Zr-Si with ZSM-5 structure by hydrothermal method Molecular sieve, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com