Aqueous epoxy graphene anticorrosive paint

An anti-corrosion coating, water-based epoxy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as low surface energy, decreased coating adhesion, and difficulty in wetting and dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] 1. Preparation of graphene zinc powder slurry (component A)

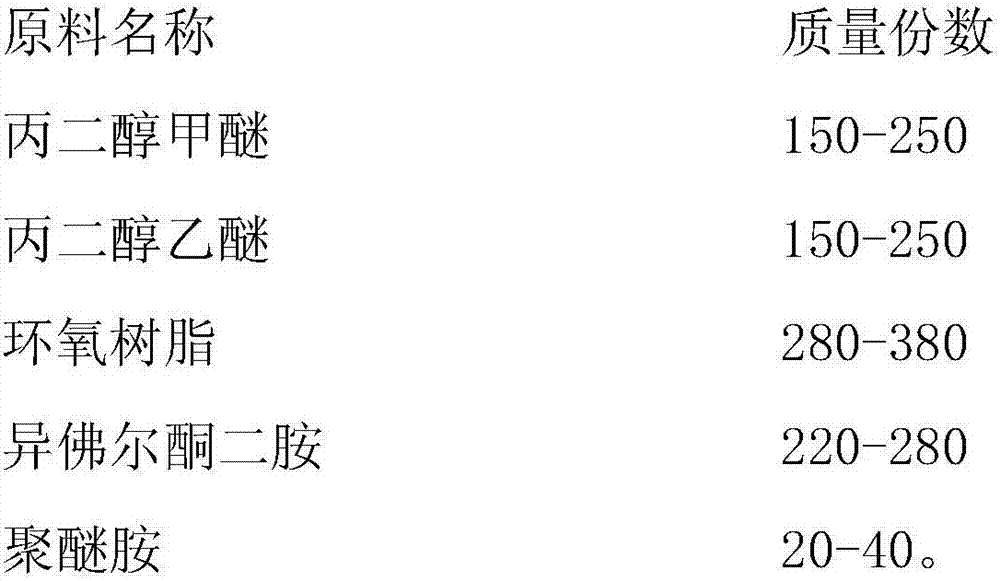

[0052] Epoxy curing agent preparation, the embodiment formula is shown in Table 1.

[0053] Table 1 Epoxy curing agent preparation embodiment

[0054]

[0055] Preparation process: Add E51 epoxy resin, propylene glycol methyl ether, and propylene glycol ethyl ether into a 2000ml flask, stir and dissolve to obtain epoxy resin liquid; add isophorone diamine and ED-600 polyetheramine into a four-neck flask, blow nitrogen, and heat To 50°C, gradually add the epoxy resin solution, control the temperature at 65-70°C, and finish the addition in about 1 hour. After the addition, continue to keep stirring at 65-70°C for 1 hour. Obtain epoxy curing agent.

[0056] It can be seen from Table 1 that when the equivalent ratio of active hydrogen to epoxy is 3.6-5:1, an epoxy curing agent in good condition can be obtained.

[0057] The graphene zinc powder slurry is prepared, and the formula is shown in Table 2.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com