Device for preparing bio-oil and fuel by using biomass and waste plastic and use method

A technology of waste plastics and biomass, which is applied in the preparation of liquid hydrocarbon mixtures, educts, petroleum industry, etc., can solve the difficulties in achieving substantial progress and breakthroughs in the coking rate of catalysts, the difference in pyrolysis characteristics of biomass and waste plastics, and the difficulty Effectively improve biomass pyrolysis gas and other problems, achieve the effect of improving anti-coking performance, reducing deactivation rate, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

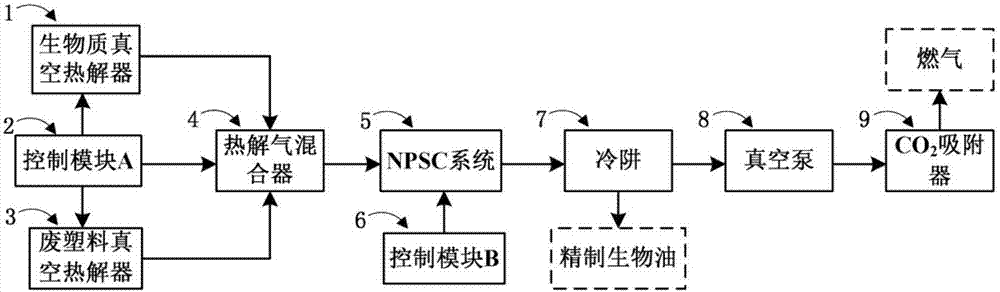

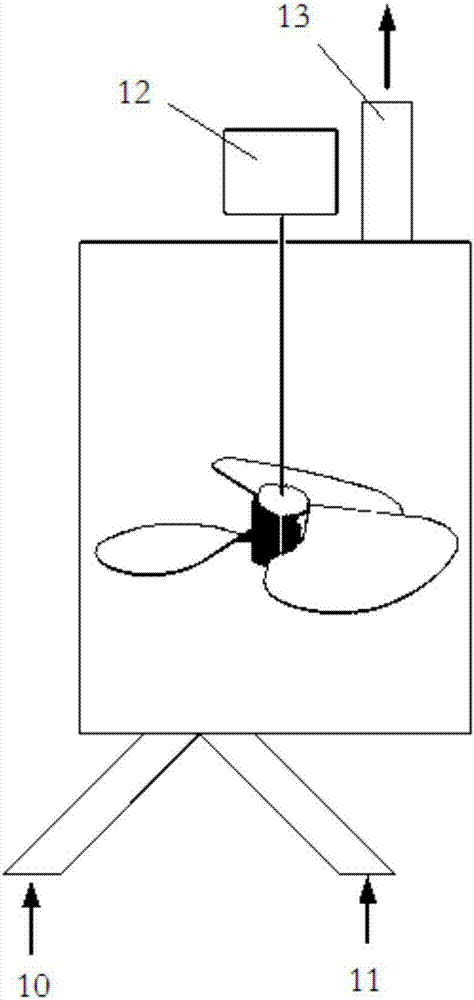

[0043] During the test, 30g of rapeseed straw and 30g of PE waste plastic were put into the biomass vacuum pyrolyzer and the waste plastic vacuum pyrolyzer respectively. ; Then under the action of control module A and control module B, start to carry out pyrolysis and catalytic reaction, adjust the heating rate of the biomass vacuum pyrolyzer to be 20°C / min, and the final temperature of pyrolysis to be 500°C, and adjust the waste plastic vacuum The heating rate of the pyrolyzer is 30°C / min, and the final pyrolysis temperature is 550°C; the temperature of the pyrolysis gas mixer 4 is maintained at 450°C; the radio frequency discharge power of the NPSC system 5 is adjusted to 50W, and the catalytic temperature is 200°C; After reacting for 30 minutes, the amount of the resulting refined bio-oil and fuel did not change.

[0044] The EA3000 elemental analyzer was used to measure the oxygen content of the refined bio-oil, and the ZDHW-5G oxygen bomb calorimeter was used to measure t...

Embodiment 2

[0048]During the test, 60g of rapeseed straw and 60g of PE waste plastic were put into the biomass vacuum pyrolyzer and the waste plastic vacuum pyrolyzer respectively, and the particle size of the raw materials were all in the range of 0.25-1.00mm; the temperature of the cold trap was adjusted to -10°C ; Then under the action of control module A and control module B, start pyrolysis and catalytic reaction, adjust the heating rate of the biomass vacuum pyrolyzer to 20°C / min, and the final pyrolysis temperature to 500°C, adjust the waste plastic vacuum The heating rate of the pyrolyzer is 30°C / min, and the final pyrolysis temperature is 550°C; the temperature of the pyrolysis gas mixer 4 is maintained at 450°C; the radio frequency discharge power of the NPSC system 5 is adjusted to 150W, and the catalytic temperature is 400°C; After reacting for 30 minutes, the amount of the resulting refined bio-oil and fuel did not change.

[0049] Through the investigation of the physical an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com