Preparation method of intelligent type oil-water separation material

An intelligent technology for oil-water separation, applied in separation methods, filtration separation, liquid separation, etc., can solve the problems of single oil-water separation method, inability to flexibly change the separation method, and inability to achieve reversible conversion of different wetting states. Simple raw material and process, low cost, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

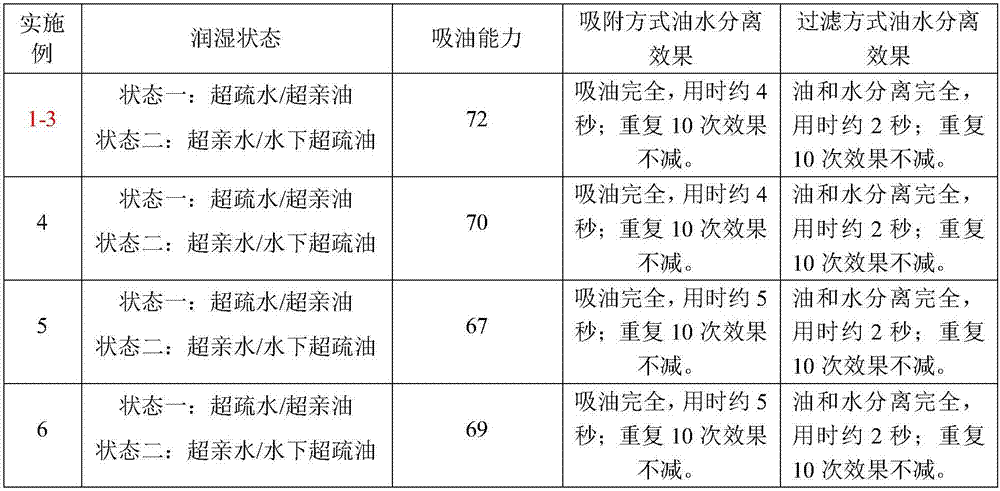

Examples

Embodiment 1

[0020] The method for preparing an intelligent oil-water separation material, the specific steps are as follows:

[0021] ①Compress the commercially available loofah pulp 40 times longitudinally and 10 times laterally to obtain compressed loofah pulp with a height of about 1 cm and a diameter of about 1 cm, and immerse the compressed loofah pulp in 0.5mol / L dilute hydrochloric acid solution for ultrasonic treatment After 2 minutes, take it out, wash it with pure water, and dry it with compressed air;

[0022] ② Submerge the compressed loofah pulp processed in step ① in 2.0mol / L copper sulfate solution for ultrasonic treatment for 3 hours, then take out the compressed loofah pulp, pre-freeze it at -20°C for 3 hours, and then place it at -40°C ℃, 1Pa pressure, freeze-drying for 36 hours, take out the loofah pulp compressed block, and heat it in the air at 180 ℃ for 6 hours;

[0023] ③The compressed loofah pulp processed in step ② is subjected to plasma treatment for 15 minutes....

Embodiment 2

[0025] Further, on the basis of Example 1, 4. the superhydrophobic / superoleophilic oil-water separation material obtained in step 3. was subjected to infrared radiation treatment for 30 minutes, and the light source for infrared radiation treatment was a 275W infrared lamp, and the distance from the surface of the material was 4cm, i.e. A super-hydrophilic / underwater super-oleophobic oil-water separation material is obtained, which is used as a filter-type oil-water separation material to filter and separate water and oil to achieve oil-water separation.

Embodiment 3

[0027] Further, on the basis of Example 2, 5. the super-hydrophilic / underwater super-oleophobic oil-water separation material obtained in step 4. was then subjected to plasma treatment for 15 minutes, and the plasma treatment took high-purity nitrogen as the gas source, and the vacuum degree was 20Pa, power 50W, that is, a superhydrophobic / superoleophilic oil-water separation material, which is used as an adsorption-type oil-water separation material to absorb oil in water to achieve oil-water separation.

[0028] The above steps ③, ④ and ⑤ can be repeated many times, so as to realize the reversible conversion between the superhydrophobic / superoleophilic and superhydrophilic / underwater superoleophobic wetting states of the prepared oil-water separation material, thus obtaining the intelligent type oil-water separation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com