Ultrafiltration membrane, nanofiltration membrane and method for preparing the same and ultrafiltration-nanofiltration reversible conversion

A technology of ultrafiltration membrane and nanofiltration membrane, which is applied in the direction of chemical instruments and methods, ultrafiltration, membrane, etc., can solve the problem of poor hydrophobicity, solvent corrosion resistance and heat resistance, hydrophobicity, solvent corrosion resistance, and poor temperature resistance , hydrophobicity, poor corrosion resistance to organic solvents, etc., to achieve the effect of high molecular weight, good corrosion resistance, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 (10%-600N)

[0059] (1) Preparation of tertiary amine-containing diamine compound:

[0060] Add 389g of N,N'-bis(p-fluorobenzoyl-3-aminopropyl)methanamine, 255g of p-aminothiophenol, 138g of potassium carbonate, and 1500g of N,N-dimethylformamide into the reaction kettle , under the protection of nitrogen, dehydration reaction at 130 ° C for 0.5 h, and then at 155 ° C for 12 h, and finally the resulting reaction solution was cooled to room temperature, and poured into water while stirring to obtain the crude product of diamine containing tertiary amine; The above crude product was washed 4 times with deionized water, the filter cake was collected, and dried at a temperature of 80°C for 8 hours to obtain a purified tertiary amine-containing diamine compound, whose structural formula is as follows:

[0061]

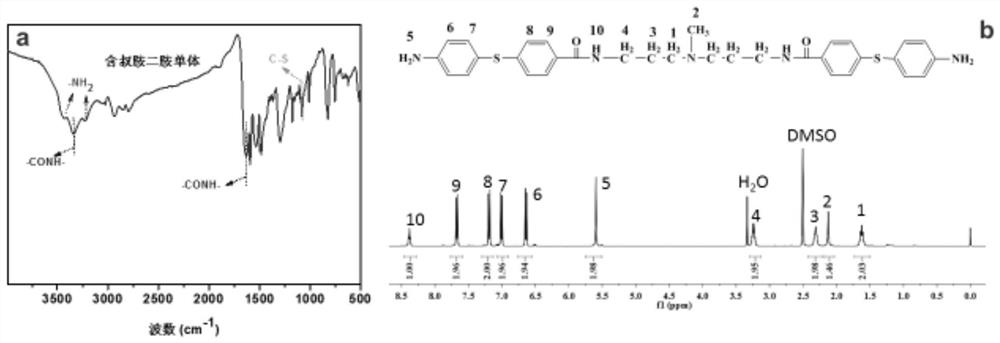

[0062] Its infrared and NMR figure 1 As shown, 3436, 3216cm -1 Absorption peak for amine group, 1082cm -1 is the absorption peak of -S-; each proton...

Embodiment 2

[0075] Example 2 (20%-600N)

[0076] (1) Preparation of tertiary amine-containing diamine compound:

[0077] Add 389g of N,N'-bis(p-fluorobenzoyl-3-aminopropyl)methanamine, 255g of p-aminothiophenol, 138g of potassium carbonate, and 3000g of dimethyl sulfoxide into the reaction kettle, under nitrogen protection , dehydration reaction at 160°C for 1 hour, then reaction at 180°C for 12 hours, and finally the resulting reaction solution was cooled to room temperature, and poured into water while stirring to obtain a crude product containing diamine containing tertiary amine; then the above crude product was deionized Washing with water 4 times, collecting the filter cake, and drying at 80°C for 8 hours to obtain a purified tertiary amine-containing diamine compound;

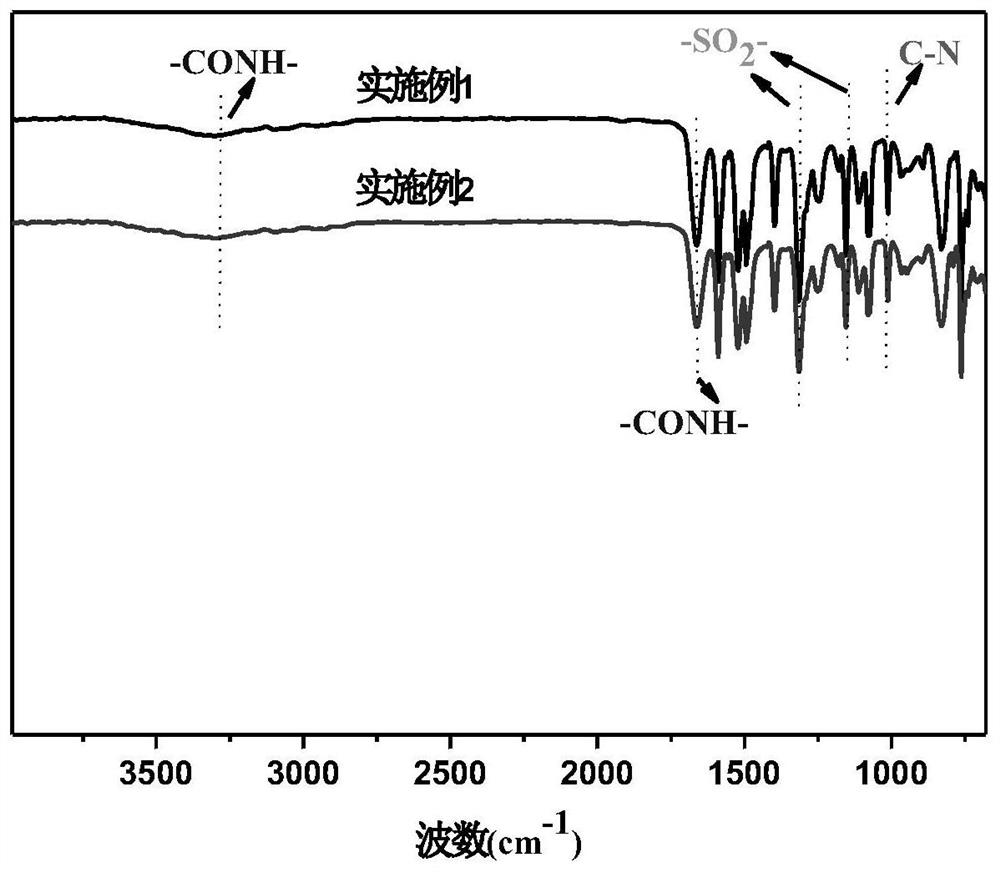

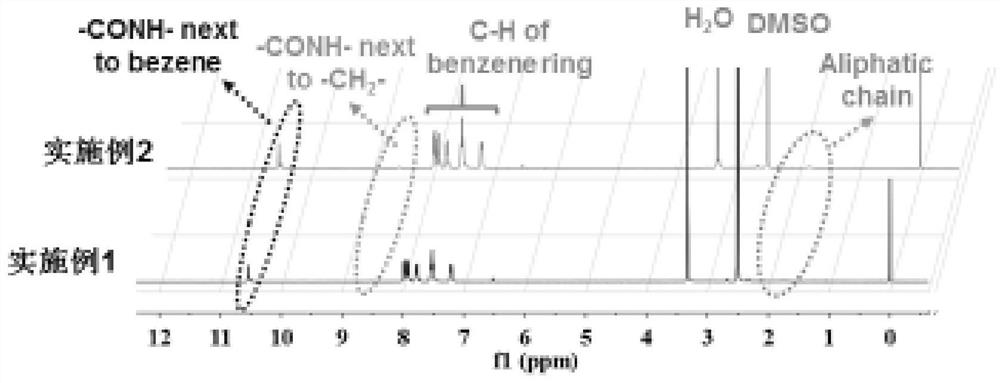

[0078] (2) Preparation of polyamide resin containing tertiary amine

[0079] Dissolve 371.2g of diamine containing sulfide sulfone, 60g of diamine containing tertiary amine prepared above, and 274g of tripropylami...

Embodiment 3

[0090] Embodiment 3 (10% 600N-80% 464-10% m-phenylenediamine-50% TDC-50% terephthaloyl dichloride)

[0091] (1) Preparation of tertiary amine-containing diamine compound:

[0092] Add 389g of N,N'-bis(p-fluorobenzoyl-3-aminopropyl)methanamine, 218g of p-aminophenol, 80g of sodium hydroxide, and 3000g of N,N-dimethylacetamide into the reaction kettle , under the protection of nitrogen, dehydration reaction at 150°C for 1 hour, then reaction at 166°C for 8 hours, and finally the resulting reaction solution was cooled to room temperature, and poured into water while stirring to obtain a crude product containing diamine containing tertiary amine; The crude product was washed 5 times with deionized water, the filter cake was collected, and dried at a temperature of 90°C for 12 hours to obtain a purified diamine compound containing a tertiary amine, whose structural formula is as follows:

[0093]

[0094] (2) Preparation of polyamide resin containing tertiary amine

[0095] 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com