Si-Sb-Se phase changing thin-film material used for phase changing memory

A technology of phase change memory, si-sb-se, applied in the direction of static memory, digital memory information, information storage, etc., can solve the problem that the operation speed of phase change memory cannot be fast, the volume change of amorphous and polycrystalline transformation is large, and the unfavorable Long-term stable operation of the device and other issues, to achieve good data retention characteristics, fast crystallization speed, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The Si-Sb-Se phase change film material provided by the present invention has a specific component of Si c Sb a Se b ,among them:

[0023] 48≤b≤60, 20≤a≤40, 8≤c≤40, a+b+c=100;

[0024] Preferably, the material composition of the Si-Sb-Se phase change film provided by the present invention is specifically Si 22 Sb 22 Se 56 , Si 14 Sb 29 Se 57 , Or Si 8 Sb 33 Se 59 .

[0025] Si c Sb a Se b Can also be expressed as Si y (Sb x Se 100-x ) 100-y form,

[0026] Among them, y=c, x(100-y)=a, and (100-x)(100-y)=b.

Embodiment 2

[0028] The Si-Sb-Se phase change film material provided by the present invention has a specific component of Si c Sb a Se b ,among them:

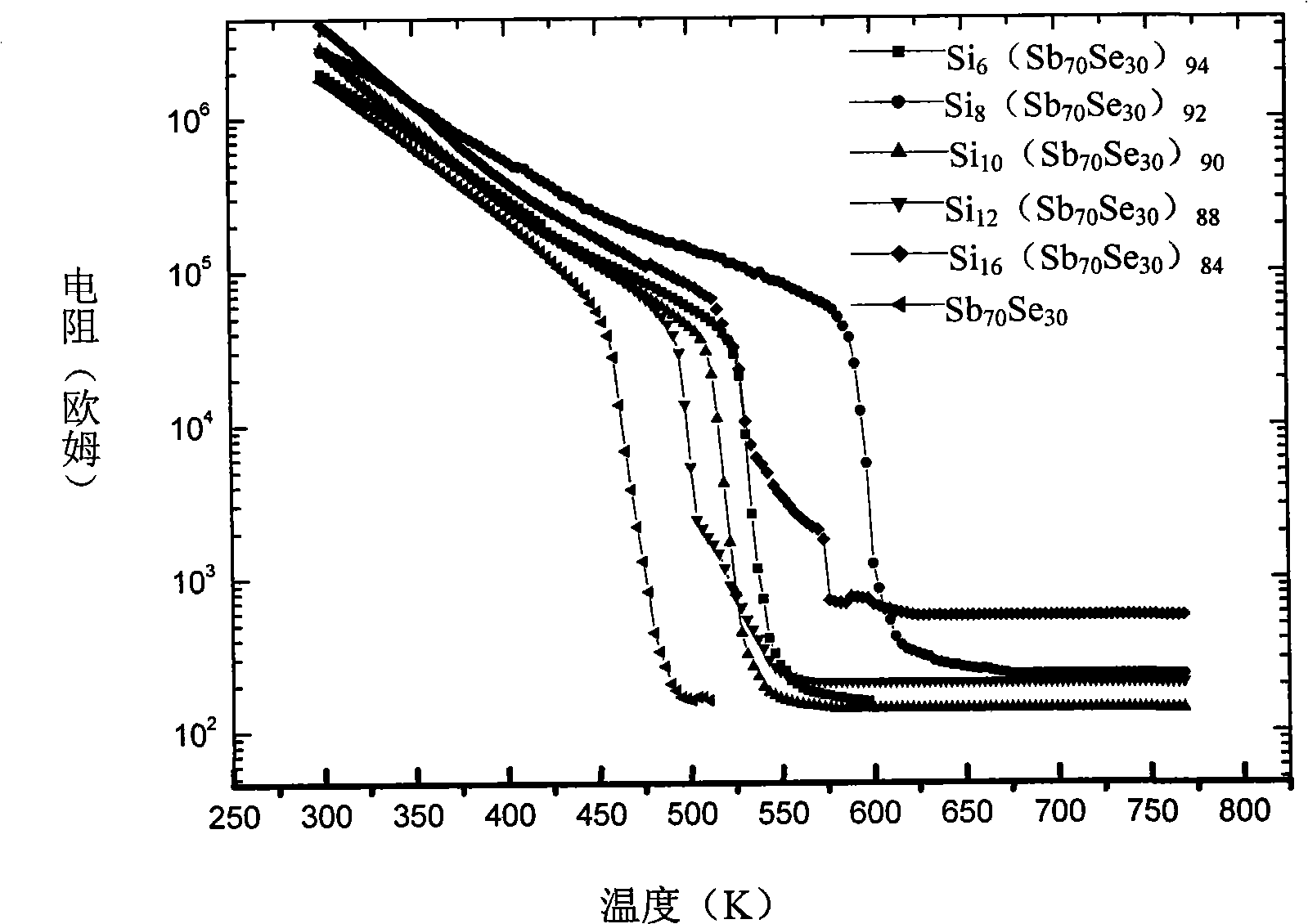

[0029] 60≤b≤80, 20≤a≤40, 3≤c≤20, a+b+c=100;

[0030] Preferably, when the expression form is (Sb x Se 1-x ) 1-y Si y When the material composition of the Si-Sb-Se phase change film provided by the present invention is specifically Si 10 (Sb 70 Se 30 ) 90 , Si 5 (Sb 70 Se 30 ) 95 .

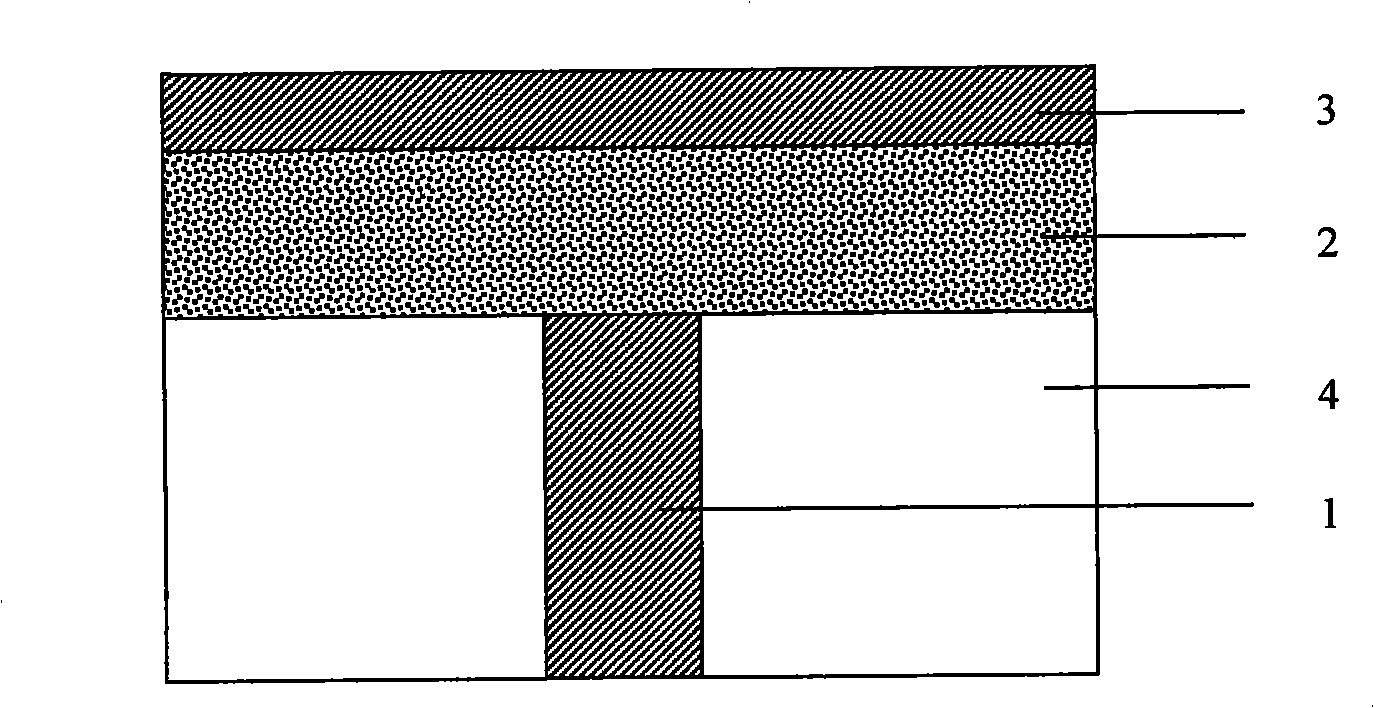

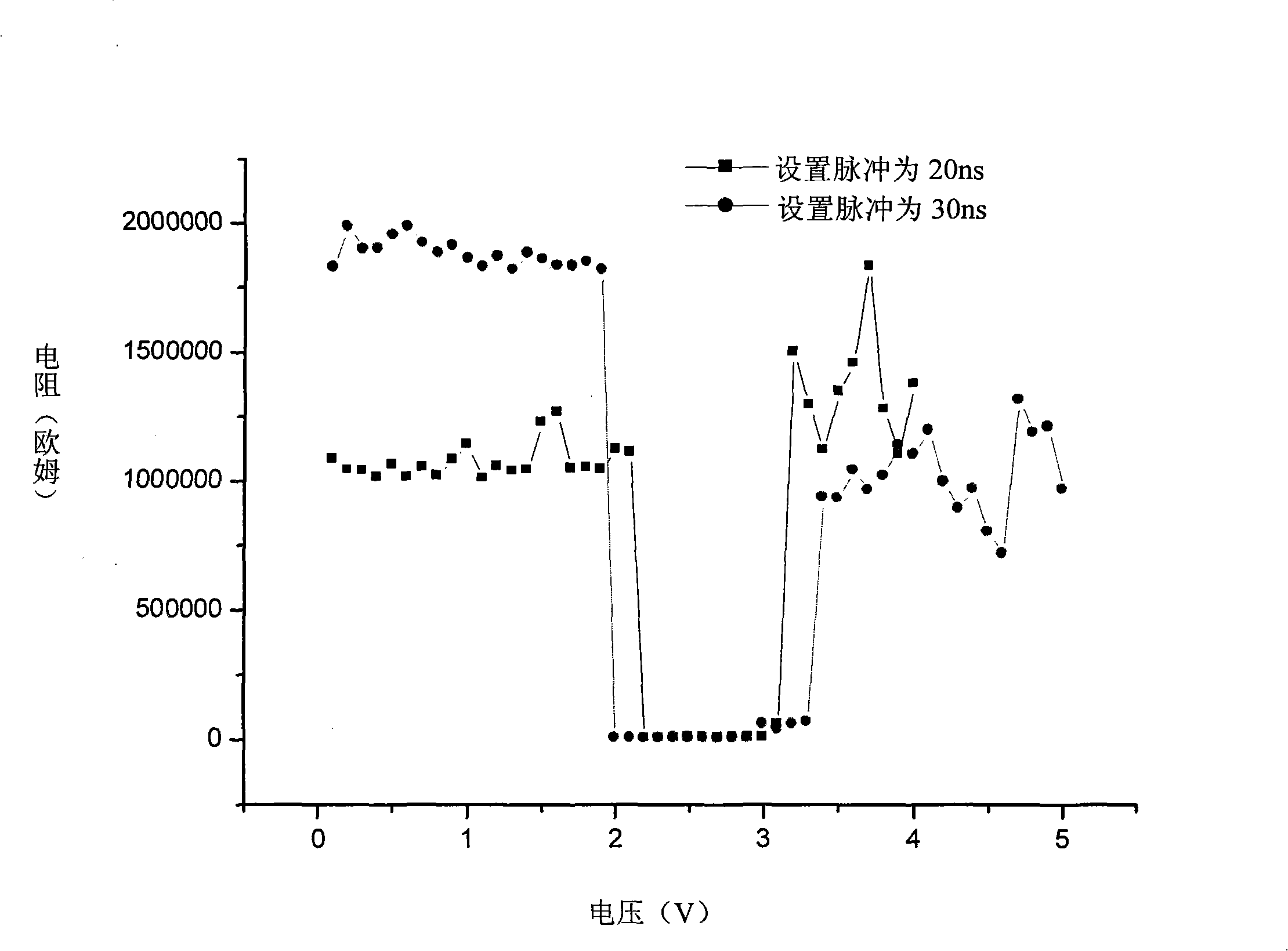

[0031] The Si-Sb-Se phase change film material of the present invention can be prepared by a multi-target co-sputtering method. The required component ratio can be obtained by adjusting the power corresponding to different targets. The Si-Sb-Se phase change film material can also be prepared by a single target sputtering method with an alloy target. The material can be prepared by chemical vapor deposition methods, including atomic layer deposition (ALD), or by electron beam evaporation, pulsed laser deposition, or by ion implantation of element Si in the Si-Sb-Se fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com