A treatment system for fluorine-containing flue gas and its application method

A treatment system and flue gas technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of short equipment life, difficult replacement, large equipment footprint, etc., and achieve the effect of improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

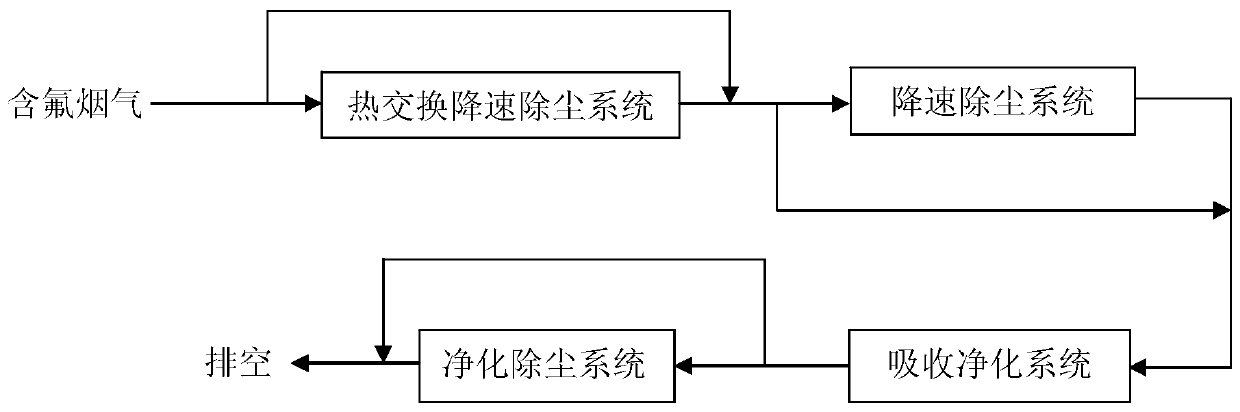

[0073] according to figure 1 As shown, design the fluorine-containing flue gas treatment system of the present embodiment;

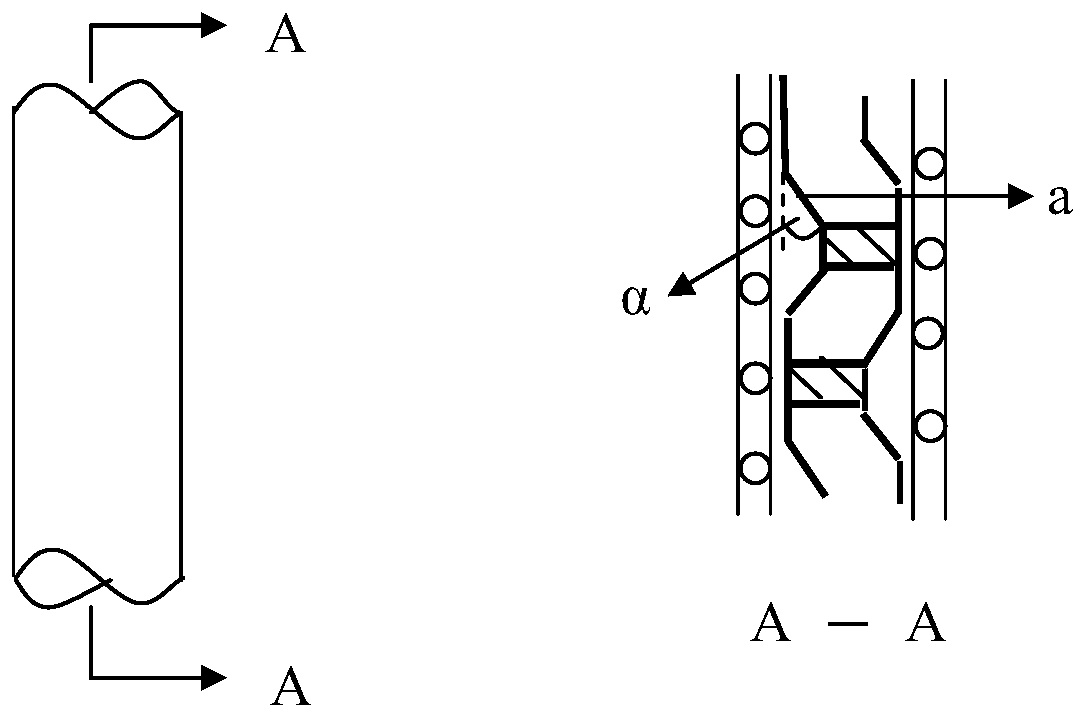

[0074] according to figure 2 Design the pipeline in the heat exchange dedusting system. The pipeline in the dedusting system is different in that there is no heat exchange equipment. In this implementation, the heat exchange device is a copper pipe through which a heat conducting medium (including water) passes.

[0075] In this example,

[0076] The lining material A1-1 in the heat exchange dedusting system adopts carbonaceous material system Y, and the component design is carried out according to graphite powder: graphite fiber: asphalt powder = 65:25:10;

[0077] For graphite powder and asphalt powder, the ratio (mass ratio) of 40-60 mesh: 60-100 mesh: 100-200 mesh: 200 mesh or more = 17:28:45:10 is used to prepare the powders of each particle size section and mix them. Mix evenly; then design the ingredients according to the components; firstly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com