Desulphurization adsorbent regeneration method, and sulfur containing hydrocarbon adsorption desulphurization method and device

A technology of adsorbent regeneration and adsorbent, which is applied in the field of sulfur-containing hydrocarbon desulfurization, can solve the problems of desulfurization efficiency decrease, agent consumption increase, and activity reduction, etc., and achieve the effect of increasing regeneration rate, increasing temperature, and reducing adsorbent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] It is used to illustrate the beneficial effects of the sulfur-containing hydrocarbon adsorption desulfurization method of the present invention.

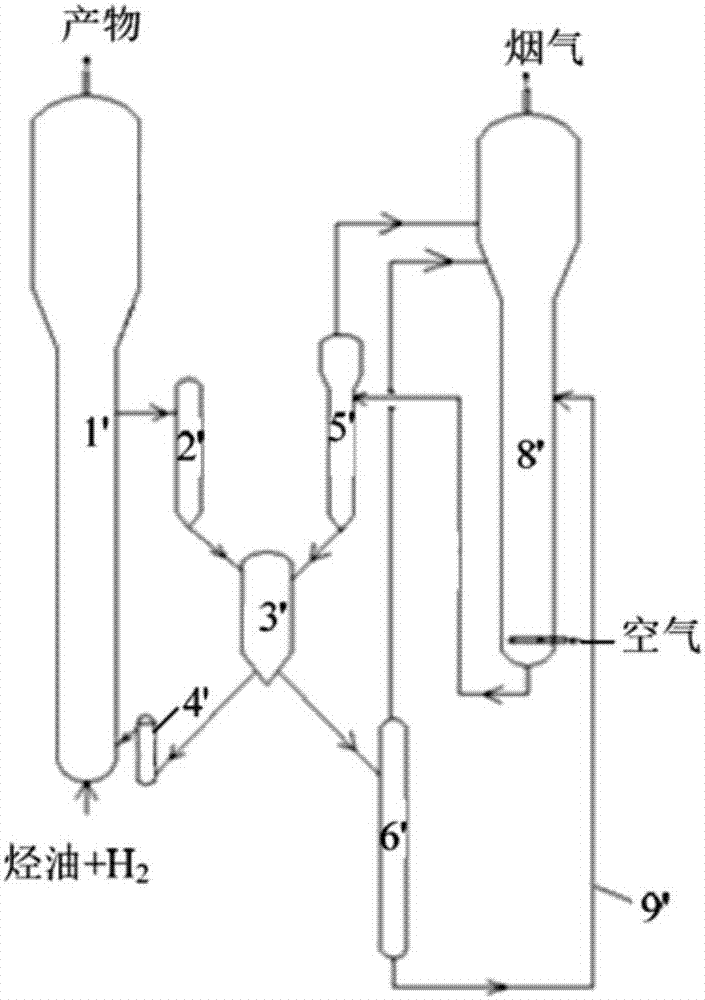

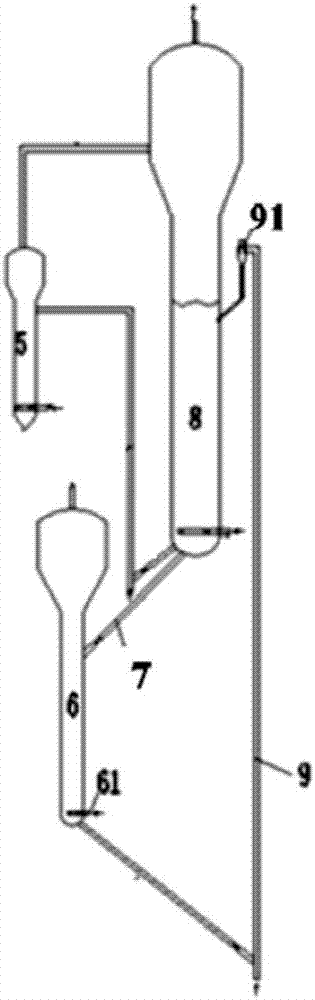

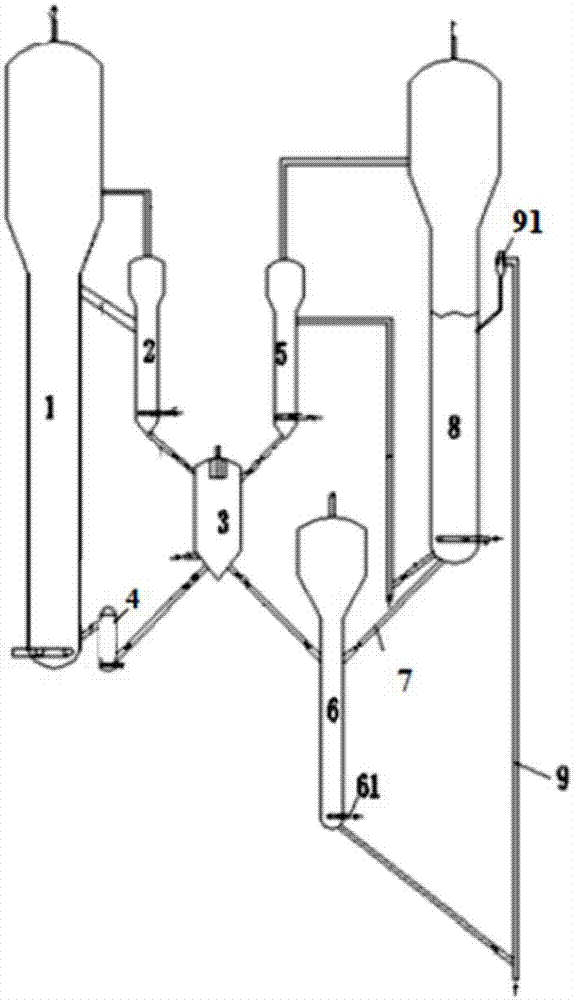

[0067] Sulfur-containing hydrocarbon adsorption desulfurization method: adopt image 3 The shown sulfur-containing hydrocarbon adsorption desulfurization device (wherein the delivery vertical pipe in the spent agent delivery pipeline 9 may have a structure with a wide bottom and a narrow top). And the gasoline of the composition shown in Table 1 is used as sulfur-containing hydrocarbon, and the adsorbent shown in Table 2 is passed into the aforementioned sulfur-containing hydrocarbon adsorption desulfurization device for adsorption desulfurization treatment, wherein:

[0068] (1) Desulfurization process (processing in reactor 1): using hydrogen as the hydrogen supply medium at a temperature of 410°C, a pressure of 2.8MPa, and a gasoline weight hourly space velocity of 4h -1 1. The molar ratio of hydrogen to gasoline is to ca...

Embodiment 2

[0075] It is used to illustrate the beneficial effects of the sulfur-containing hydrocarbon adsorption desulfurization method of the present invention.

[0076] Sulfur-containing hydrocarbon adsorption desulfurization method: with reference to Example 1, the differences are as follows:

[0077] (2) Regeneration treatment:

[0078] Coke condensation treatment (carried out in the regenerator feed tank 6): use nitrogen as the stripping gas, mix the sulfur-laden standby agent and the refluxed regenerating agent, at a temperature of 400°C and a pressure of 0.2MPa, strip the gas The superficial gas velocity is 0.05m / s and the decoking standby agent is obtained by staying for 60 minutes.

[0079] Primary regeneration treatment (carried out in the spent agent delivery pipeline 9): with the mixed gas of air and nitrogen (the oxygen content is 15% by volume, and the preheating temperature is 200° C.) as the first regeneration gas, the decoked spent agent is heated at a temperature of ...

Embodiment 3

[0083] It is used to illustrate the beneficial effects of the sulfur-containing hydrocarbon adsorption desulfurization method of the present invention.

[0084] Sulfur-containing hydrocarbon adsorption desulfurization method: with reference to Example 1, the differences are as follows:

[0085] (2) Regeneration treatment:

[0086] Coke condensation treatment (carried out in the regenerator feed tank 6): use nitrogen as the stripping gas, mix the sulfur-laden standby agent and the refluxed regenerating agent, at a temperature of 600°C, a pressure of 0.1MPa, stripping the gas Stay for 10 minutes under the condition of superficial gas velocity of 0.3m / s to obtain decoking standby agent.

[0087] Primary regeneration treatment (carried out in the spent agent delivery pipeline 9): with the mixed gas of air and nitrogen (the oxygen content is 15 volume %, the preheating temperature is 150 ℃) as the first regeneration gas, decoking the spent agent at a temperature of 320° C., press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com