Clean diethylamine production method

A technology of clean production and diethylamine, applied in separation methods, chemical instruments and methods, general water supply saving, etc., can solve problems such as high cost, large dosage of chemicals, inability to carry out biochemical treatment, etc., and achieve good society and economy Benefits, the effect of achieving zero emissions in clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

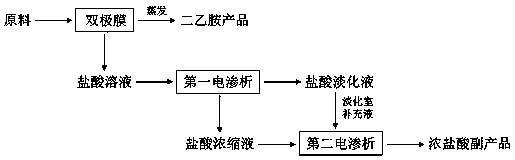

[0025] The present invention will be described in further detail with reference to the accompanying drawings and specific embodiments.

[0026] A zero-discharge method for clean production of diethylamine, comprising the following steps: passing diethylamine hydrochloride wastewater as a raw material solution into an alkali liquor chamber of a bipolar membrane device, and obtaining the product diethylamine in the alkali liquor chamber after treatment , the content of diethylamine in the product is higher than 99% and the chloride ion is lower than 0.1%. The fresh water is passed into the acid solution chamber of the bipolar membrane device, and the treated acid solution chamber obtains a hydrochloric acid solution. The hydrochloric acid solution obtained by the bipolar membrane device is passed into the first electrodialysis device as a raw material solution, the hydrochloric acid solution obtained by the bipolar membrane device of 6L is added to the desalination chamber, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com