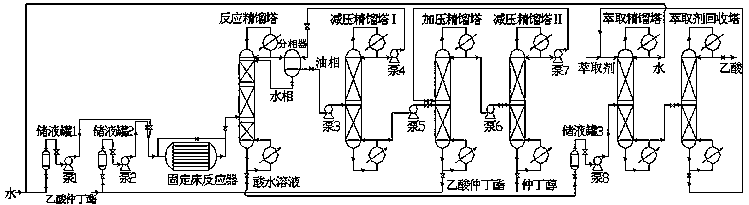

Method for producing high-purity sec-butyl alcohol through joint of fixed bed and reaction rectification

A fixed-bed reactor, reactive distillation technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve the problem of low conversion rate, achieve stable product quality and improve production Scale, the effect of improving the hydrolysis conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The feed molar ratio of sec-butyl acetate to water is 2, the fixed bed temperature is 110°C; the reflux ratio of the reactive distillation column is 2, and the operating pressure is 0.2MPa; the operating pressure in the vacuum distillation column is 5kPa, and the reflux ratio is 2 ; The operating pressure in the pressurized rectification tower is 0.6MPa, and the reflux ratio is 2.

[0032] In this example, the hydrolysis conversion rate of sec-butyl acetate was 71.55%, the purity of sec-butanol was 99.97%, and the yield of sec-butanol was 91.23%.

Embodiment 2

[0034] The feed molar ratio of sec-butyl acetate to water is 5, the fixed bed temperature is 110°C; the reflux ratio of the reactive distillation column is 8, and the operating pressure is 0.3MPa; the operating pressure in the vacuum distillation column is 10kPa, and the reflux ratio is 5 ; The operating pressure in the pressurized rectification tower is 1.0MPa, and the reflux ratio is 5.

[0035] In this example, the hydrolysis conversion rate of sec-butyl acetate was 82.91%, the purity of sec-butanol was 99.97%, and the yield of sec-butanol was 95.52%.

Embodiment 3

[0037] The feed molar ratio of sec-butyl acetate to water is 5, the fixed bed temperature is 110°C; the reflux ratio of the reactive distillation column is 10, and the operating pressure is 0.5MPa; the operating pressure in the vacuum distillation column is 50kPa, and the reflux ratio is 8 ; The operating pressure in the pressurized rectification tower is 1.3MPa, and the reflux ratio is 8.

[0038] In this example, the hydrolysis conversion rate of sec-butyl acetate was 83.37%, the purity of sec-butanol was 99.93%, and the yield of sec-butanol was 96.77%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com