Method for deeply desulfurizing sulfur-containing raw material

A deep desulfurization and raw material technology, applied in the distillation control/regulation of hydrocarbon oil, petroleum industry, hydrocarbon oil treatment, etc., can solve the problems of reducing solvent sulfide, unfavorable octane number, solvent purity decline, etc., and achieve octane number lossless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

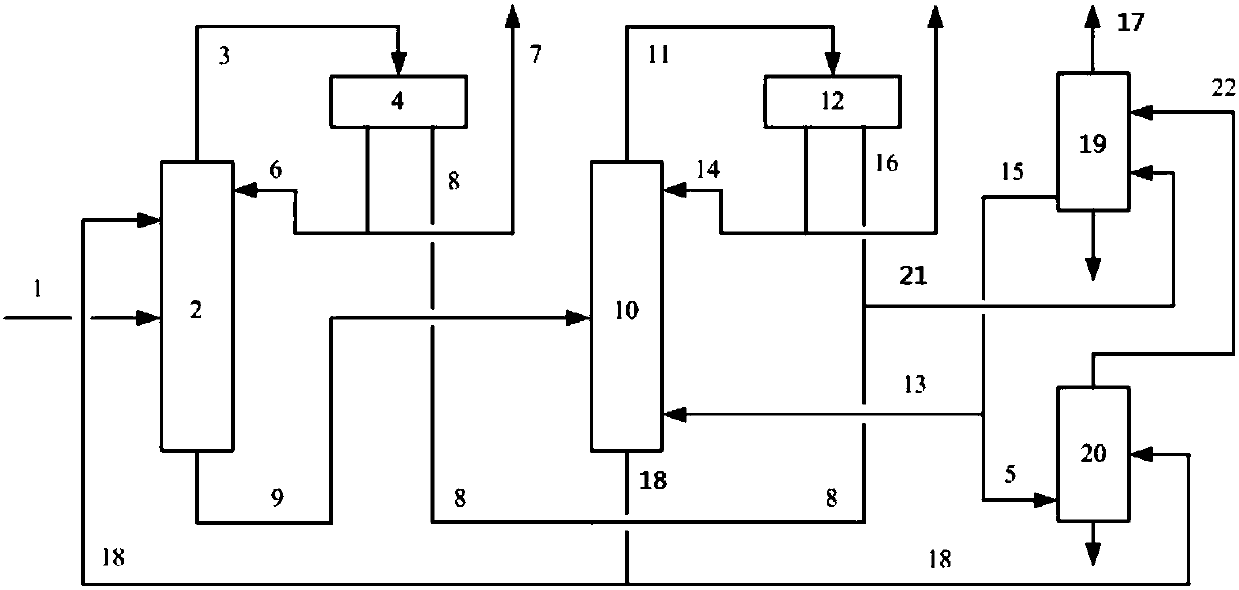

[0103] This embodiment adopts figure 1 The process flow shown is for advanced desulfurization treatment of gasoline raw material A.

[0104] The gasoline raw material A has a distillation range of 60-120° C. and a sulfur content of 400 μg / g.

[0105] In the solvent extraction system, the gasoline raw material is subjected to solvent extraction distillation in a solvent extraction distillation tower to obtain desulfurized gasoline products and sulfur-containing solvents. The sulfur-containing solvent is then separated from the sulfide contained therein by distillation in a solvent recovery tower to obtain the solvent-extracted sulfur-containing material and the recovered solvent from which the sulfide has been removed:

[0106] In the solvent extraction distillation tower: the feed weight ratio of the extraction solvent to the gasoline raw material is 3:1, the temperature at the bottom of the tower is 170°C, the temperature at the top of the tower is 80°C, and the pressure at ...

Embodiment 2

[0113] This embodiment adopts figure 1 The process flow shown is for deep desulfurization of gasoline feedstock B.

[0114] The gasoline raw material B has a distillation range of 27-100°C and a sulfur content of 450 μg / g, among which the sulfur content of mercaptans is 50 μg / g.

[0115] And the gasoline raw material B is subjected to alkali washing pretreatment to wash away part of light mercaptans, and the alkali solution for alkali washing is a NaOH aqueous solution with a mass fraction of 15% by weight. The sulfur content in the gasoline raw material obtained after alkali washing is 425 μg / g, and the sulfur content in mercaptan is 25 μg / g.

[0116] In the solvent extraction system, solvent extraction distillation is performed on the gasoline raw material after alkali washing in the solvent extraction distillation tower to obtain desulfurized gasoline products and sulfur-containing solvents. The sulfur-containing solvent is then separated from the sulfide contained therei...

Embodiment 3

[0124] Present embodiment adopts the technological process similar to embodiment 1 to carry out, difference is:

[0125] The raw material used in this example is gasoline raw material C, and the distillation range of gasoline raw material C is 33-205° C., and the sulfur content is 253 μg / g.

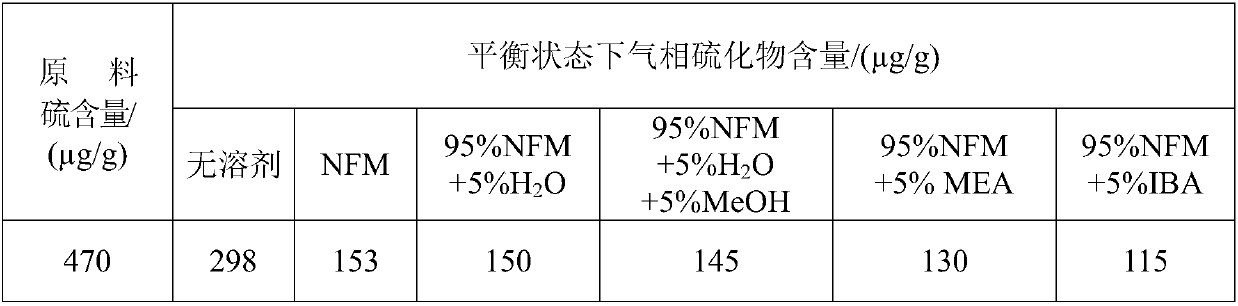

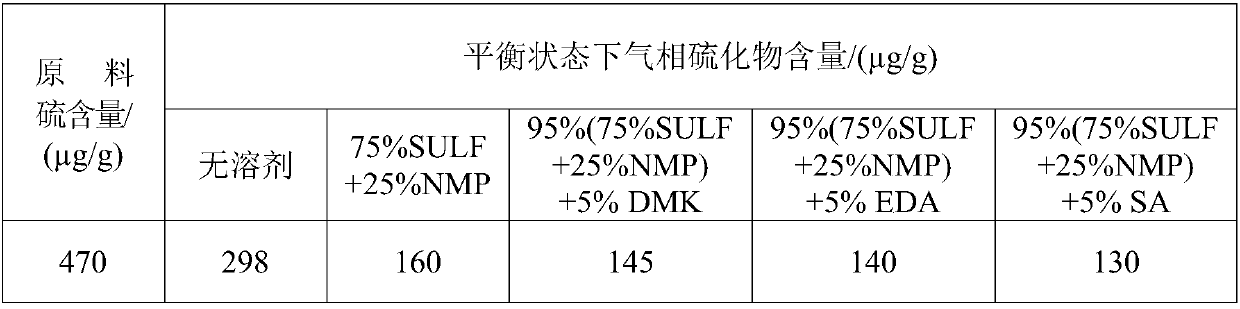

[0126] The extraction solvent that uses is the mixed solvent (wherein, the massfraction of ethylenediamine is 5% by weight, the mixed solvent (wherein, the massfraction of ethylenediamine is 5% by weight) of the sulfolane containing ethylenediamine (EDA) and N-methyl-2-pyrrolidone, and the mixture mark is 95% (75SULF / 25NMP )+5%EDA).

[0127] All the other are the same as in Example 1.

[0128] As a result, the sulfur content of the resulting gasoline product was ≯10 μg / g.

[0129] Moreover, in this embodiment, since the extraction solvent containing additives is used in the extraction distillation, the effective utilization rate of the extraction solvent is significantly improved, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com