Comprehensive utilization method for folium eucommiae and cortex eucommiae

A technology of eucommia ulmoides leaves and eucommia ulmoides, which is applied in the field of comprehensive utilization of eucommia ulmoides leaves or eucommia bark, which can solve the problem of inability to realize the comprehensive development and utilization of eucommia ulmoides leaves or eucommia bark, the inability to completely open the cell wall of plant tissue, and the discount of the health care effect of fine powder and other problems, to achieve the effect of mild action conditions, short action time, high extraction rate and content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

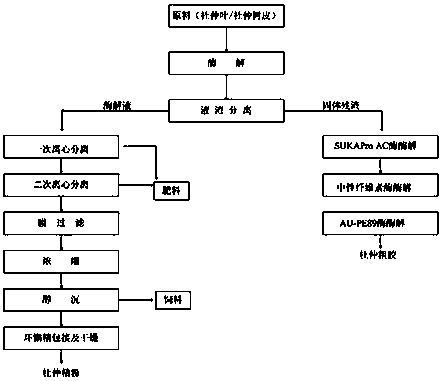

Method used

Image

Examples

Embodiment 1

[0047] (1) Use non-ground Eucommia leaves as raw materials to remove sediment and sundries;

[0048] (2) Na 2 HPO 41. Citric acid is made into a buffer solution I with a pH of about 3.0, and the mass concentration of the buffer solution I is about 1.3%;

[0049] Take SUKAPro AC enzyme accounting for 4% of the weight of raw material Eucommia leaves and dissolve it in buffer solution I to obtain mixed solution enzyme solution I (the enzyme activity of SUKAPro AC enzyme is 90u / mL;); the weight ratio of raw material Eucommia leaves to enzyme solution I For: 1:3;

[0050] Add Eucommia ulmoides leaves and enzyme solution I into the enzymolysis reaction rotary tank and perform enzymolysis at 50°C for 10 hours to obtain enzymolysis solution I;

[0051] Separating the enzymolysis solution I, the solid residue I containing glue is still kept in the enzymolysis reaction rotary tank for standby; the discharged enzymolysis solution I enters the process of preparing Eucommia fine powder;...

Embodiment 2

[0081] (1) take Eucommia bark as raw material, remove the rough bark on the surface of the bark, and keep the inner layer of clean bast containing glue;

[0082] (2) Na 2 HPO 4 1. Citric acid is made into a buffer solution I with a pH of about 3.0, and the mass concentration of the buffer solution I is about 1.3%;

[0083] Take 3.5% SUKAPro AC enzyme (the enzyme activity of SUKAPro AC enzyme is 500u / mL;) that accounts for 3.5% of the weight of the bark of raw material Eucommia and dissolve it in buffer solution I to obtain mixed solution enzyme liquid I; the mixture of raw material Eucommia bark and enzyme liquid I The weight ratio is: 1:3;

[0084] The bark of Eucommia ulmoides and enzyme liquid I were added to the enzymatic hydrolysis reaction rotary tank and enzymolyzed at 50°C for 10 hours to obtain enzymatic hydrolysis liquid I;

[0085] Separating the enzymolysis solution I, the solid residue I containing glue is still kept in the enzymolysis reaction rotary tank for ...

Embodiment 3

[0106] Take the precipitate obtained after the alcohol precipitation in step (8) in Example 1, dry to about 5% of its moisture content, take out 5 different batches of samples (the preparation method is exactly the same, only the batches are different), Denoted as A, B, C, D, E, through microbial detection, detect their inhibitory action to escherichia coli, Staphylococcus, Salmonella, the result is as follows: (inhibition rate %)

[0107]

[0108] For the detection method, please refer to the "Porous Plate-MTT Colorimetric Method for Measuring the Inhibitory Activity of Plant Antibacterial Components on Bacteria" invented by Tang Jing, Tan Manliang and others in "China Science and Technology Papers Online";

[0109] As can be seen from the data in the above table, when the alcohol precipitation obtained in the present invention is used for feed, it has a strong inhibitory effect on Staphylococcus, and has a certain inhibitory effect on Salmonella. Therefore, after it is app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com