Method of ultrasonic combining microwave for preparing graphene quantum dots

A technology of graphene quantum dots and ultrasonic waves, applied in graphene, chemical instruments and methods, carbon compounds, etc., can solve problems such as difficult operation, harsh preparation conditions, and complicated steps, and achieve less edge defects, simple process, and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Dissolve 100mg NaOH in 100ml N-methylpyrrolidone, then add 100mg graphite, stir to disperse the graphite evenly, and obtain a mixed solution;

[0042] (2) Then the mixed solution is placed in an ultrasonic cleaner, and the ultrasonic emission power is adjusted to 400W, and the ultrasonic time is 8h; then the resulting solution is placed in an ultrasonic cell disruptor, and the ultrasonic emission power is adjusted to be 360W, and the ultrasonic time is 4h; Microwave radiation heating, microwave radiation power is 600W, radiation temperature is 100℃, heating for 1h;

[0043] (3) After the reaction, the obtained reaction solution was dialyzed with distilled water for 7 days using a 500 Da dialysis bag, filtered and concentrated to 400 μg / ml by rotary evaporation to obtain graphene quantum dots.

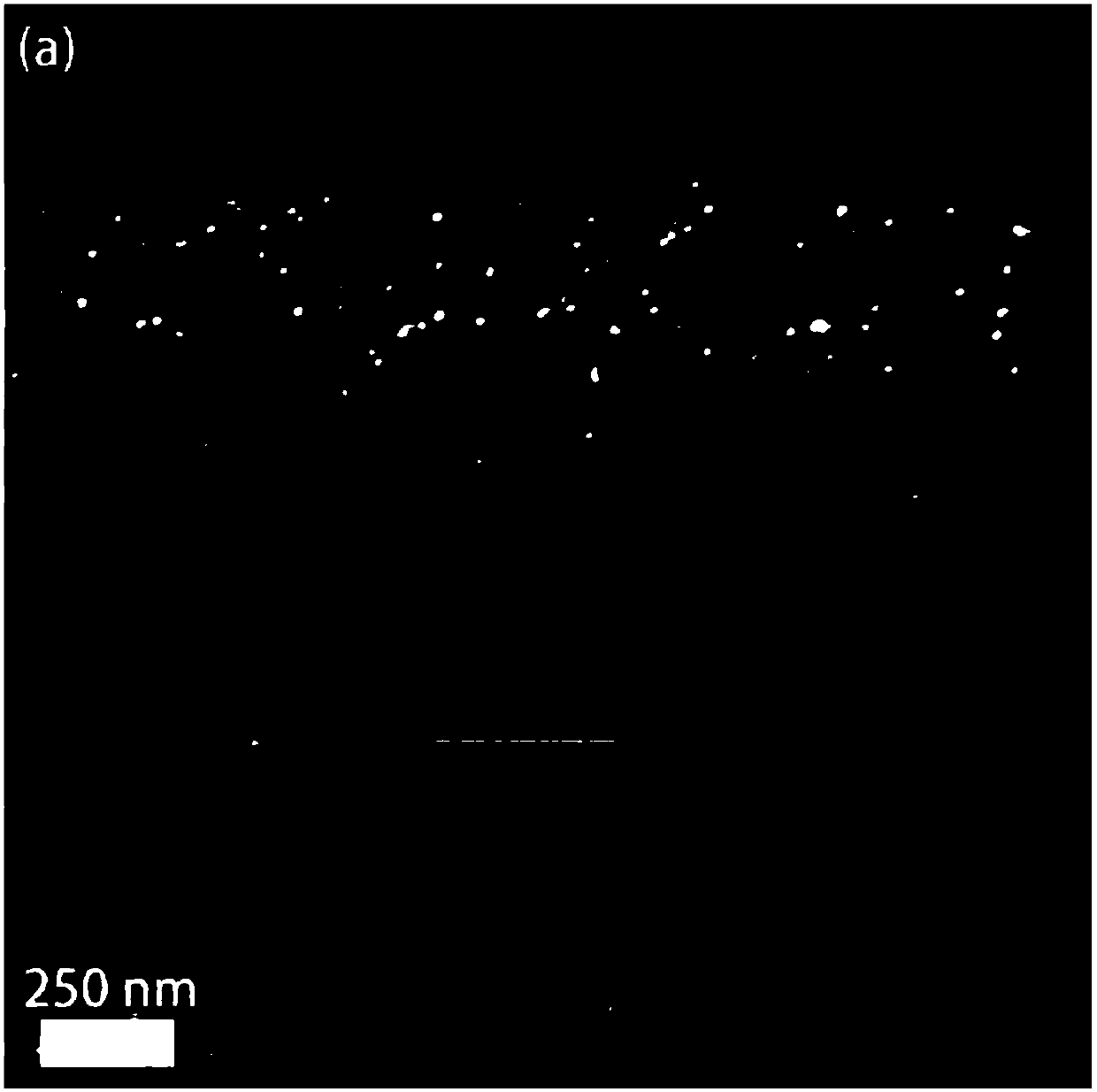

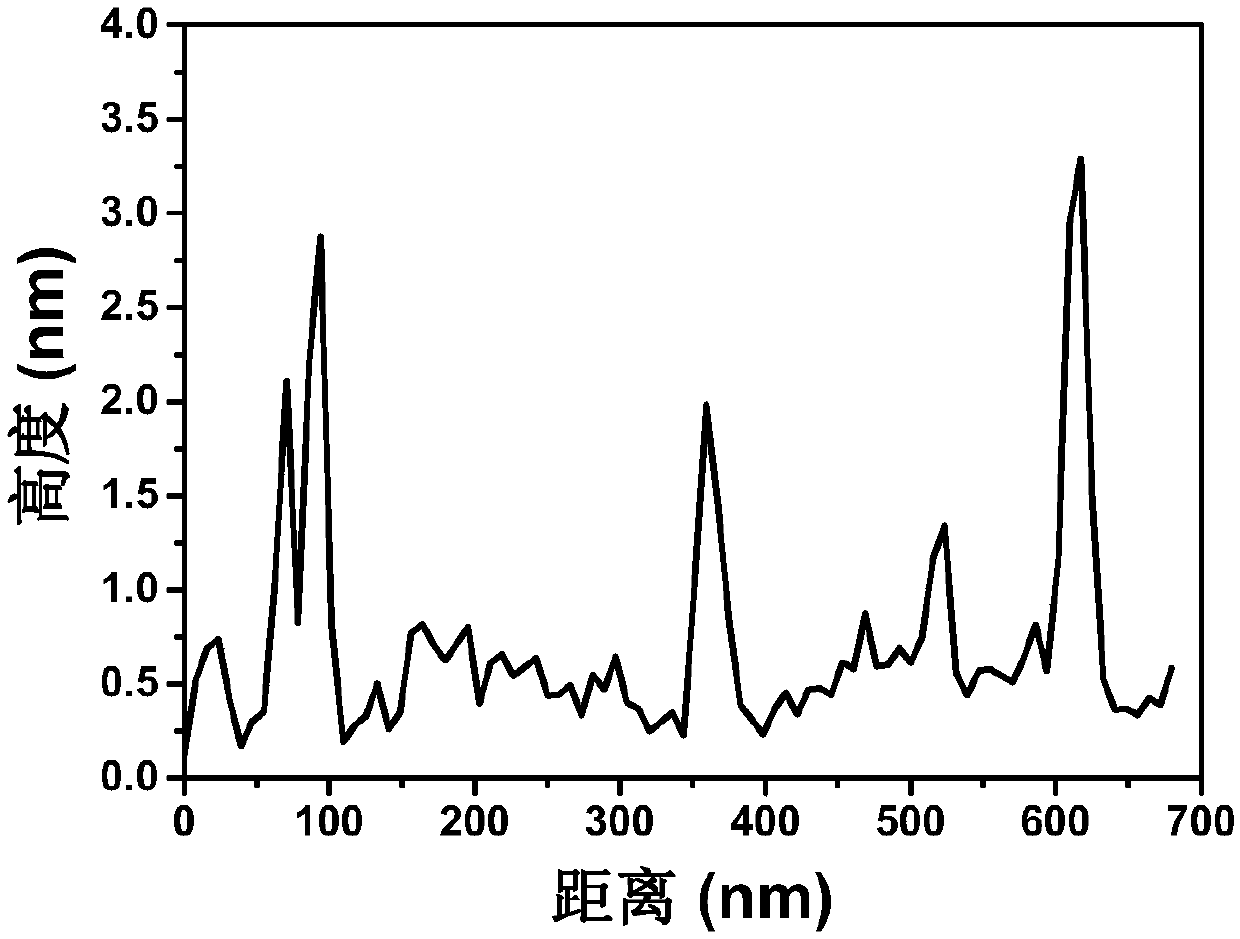

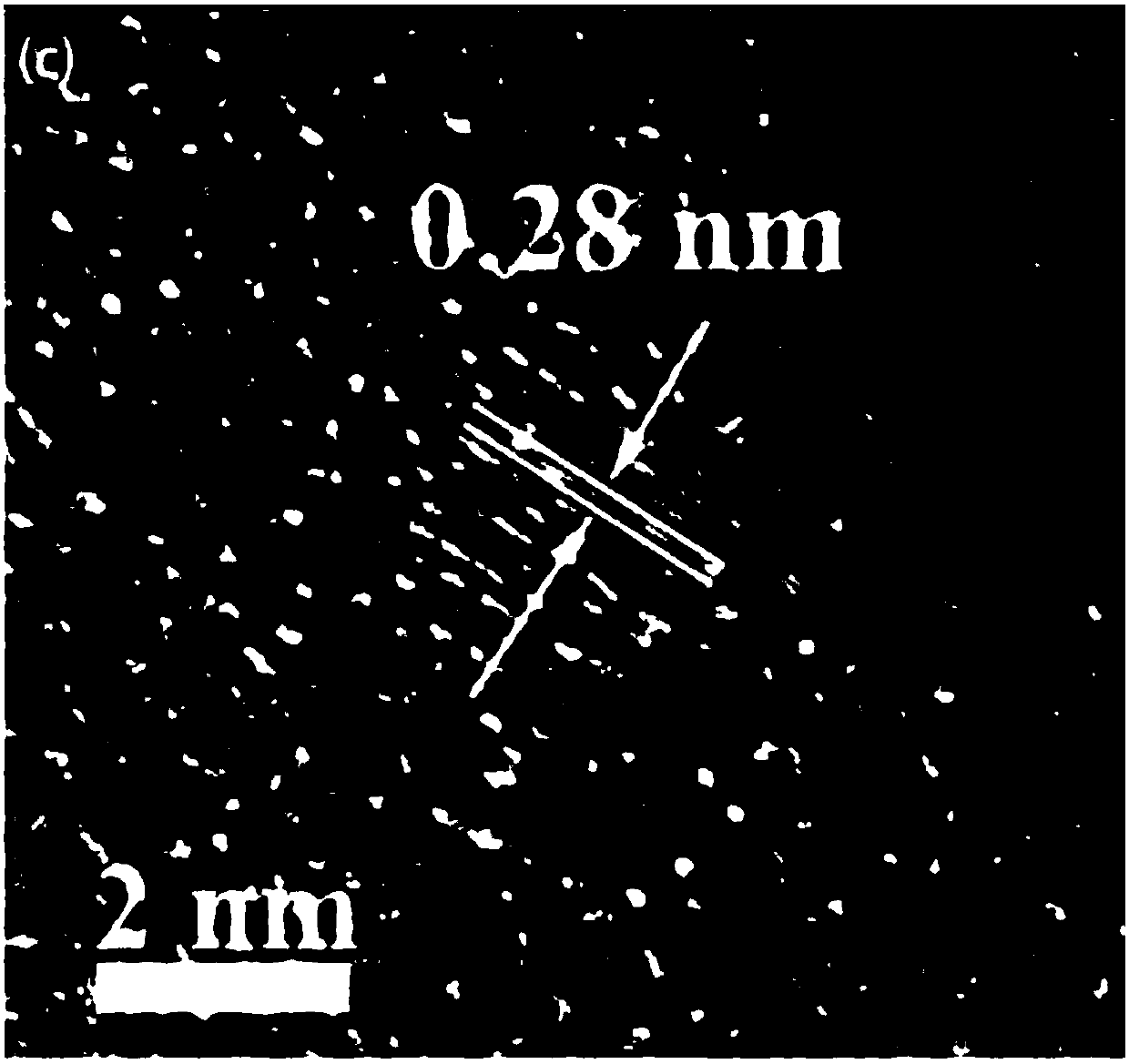

[0044] The atomic force microscope (AFM) image of the prepared graphene quantum dots is shown in Figure 1a shown, along the Figure 1a The height profile of the middle white...

Embodiment 2

[0049] (1) Dissolve 10 mg of NaOH in 90 ml of N-methylpyrrolidone, then add 100 mg of graphite, stir to disperse the graphite evenly, and obtain a mixed solution;

[0050] (2) Then the mixed solution is placed in an ultrasonic cleaner, and the ultrasonic emission power is adjusted to 160W, and the ultrasonic time is 6h; then the resulting solution is placed in an ultrasonic cell disruptor, and the ultrasonic emission power is adjusted to be 300W, and the ultrasonic time is 2h; Microwave radiation heating, microwave radiation power is 700W, radiation temperature is 110°C, heating for 0.1h;

[0051] (3) After the reaction, the resulting reaction solution was dialyzed with distilled water for 7 days using a 500 Da dialysis bag, filtered and concentrated to 450 μg / ml by rotary evaporation to obtain graphene quantum dots.

[0052] The particle size of the prepared graphene quantum dot is 1-4nm.

[0053] N-methylpyrrolidone also has fluorescence, and its fluorescence spectrum is sh...

Embodiment 3

[0057] (1) Dissolve 50mg NaOH in 80ml N-methylpyrrolidone, then add 1000mg graphite, stir to disperse the graphite evenly, and obtain a mixed solution;

[0058] (2) Then the mixed solution is placed in an ultrasonic cleaner, and the ultrasonic emission power is adjusted to 280W, and the ultrasonic time is 4h; then the resulting solution is placed in an ultrasonic cell disruptor, and the ultrasonic emission power is adjusted to be 240W, and the ultrasonic time is 0.5h; finally Heating by microwave radiation, the microwave radiation power is 800W, the radiation temperature is 110°C, and the heating time is 0.1h;

[0059] (3) After the reaction, the obtained reaction solution was dialyzed with distilled water for 5 days using a 1000 Da dialysis bag, filtered and concentrated to 500 μg / ml by rotary evaporation to obtain graphene quantum dots.

[0060] The particle size of the prepared graphene quantum dot is 4-7nm.

[0061] The fluorescence spectrum of the prepared graphene quant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com