Fade resistant color cast non-pressing pavement material and preparation method thereof

A pavement material and pouring technology, applied in the field of materials, can solve the problems of fading colored pavement, high strength of cement concrete pavement, and affecting the bonding between aggregates, etc., to improve weather resistance and durability, rapid strength growth, and early high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Preparation method of anti-fading color pouring type pressure-free pavement material:

[0042] 1) Weigh 10-15 parts of the pigment according to the mass parts and put it into 5-10 parts of water, stir well until the color is uniform;

[0043] 2) Preparation of dry powder: Mix and stir 100 parts of cement, 15-20 parts of fly ash, 100-200 parts of sand, 15-20 parts of expansion agent, 0.05-0.1 part of demulsifier and 0.001-0005 parts of aluminum powder to obtain dry powder ;

[0044] 3) Put 100 parts of dry powder prepared in step 2), 0.1-0.5 parts of water reducing agent, 3-5 parts of antioxidant, and 6-10 parts of anti-ultraviolet aging agent into the mixer at a speed of 200r / min for 60s;

[0045] 4) Add the pigment water prepared in step 1) and 10-20 parts of emulsified asphalt to the raw materials in step 3), and stir in the mixer at a speed of 200r / min for 30s;

[0046] 5) Finally, stir at a speed of 400r / min for 180s to obtain the anti-fading color cast pavement m...

Embodiment 1

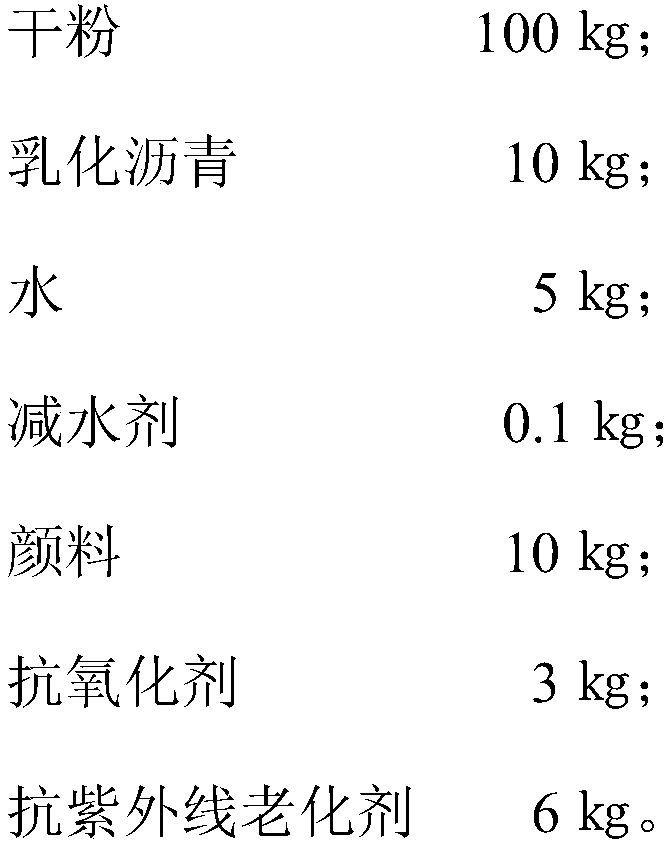

[0049] Take the following raw materials according to the parts by mass:

[0050]

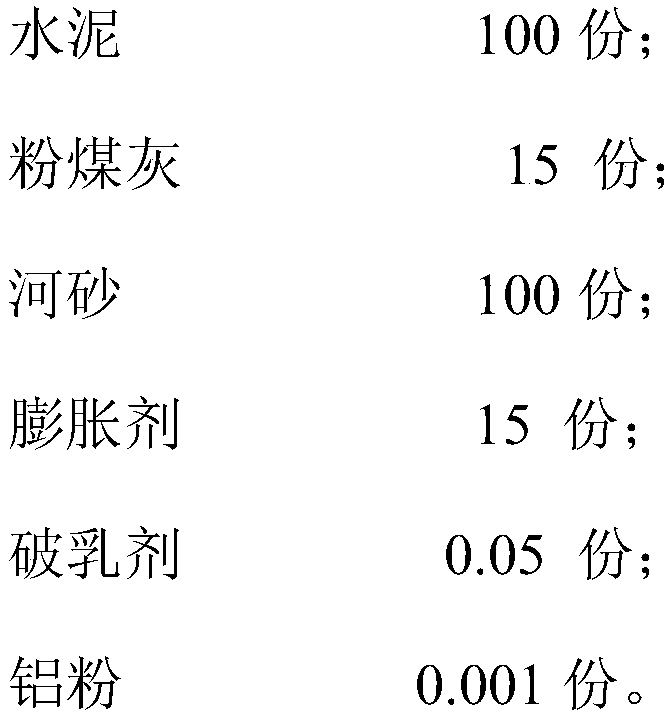

[0051] Wherein the dry powder is formed by mixing and stirring the following materials by mass:

[0052]

[0053] Weigh each raw material according to the above mixing ratio, put the weighed pigment into water, and mix it fully and evenly until the color is uniform. Weigh each raw material according to the formula, first put the dry powder and additives (water reducing agent, antioxidant, anti-ultraviolet aging agent) into the mixer and dry mix at a speed of 200r / min for 60s. Then add the prepared colored water and emulsified asphalt, stir at a speed of 200r / min for 30s; finally stir at a speed of 400r / min for 180s. The properties of the prepared mortar materials were tested, and the results are shown in Table 1.

Embodiment 2

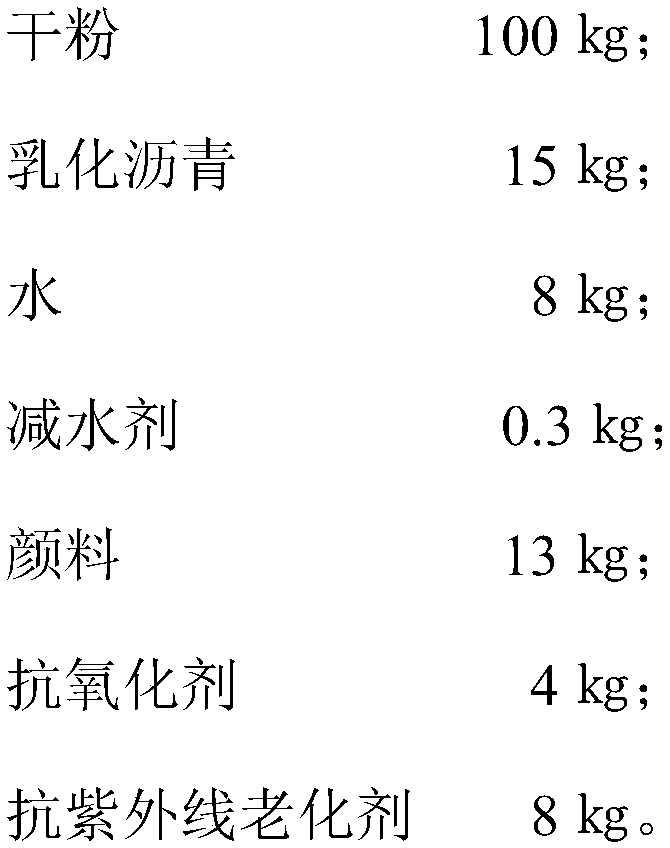

[0055] Take the following raw materials according to the parts by mass:

[0056]

[0057] Wherein the dry powder is formed by mixing and stirring the following materials by mass:

[0058]

[0059]

[0060] Weigh each raw material according to the above mixing ratio, put the weighed pigment into water, and mix it fully and evenly until the color is uniform. Weigh each raw material according to the formula, first put the dry powder and admixture into the mixer and dry mix at a speed of 200r / min for 60s. Then add the prepared colored water and emulsified asphalt, stir at a speed of 200r / min for 30s; finally stir at a speed of 400r / min for 180s. The properties of the prepared mortar materials were tested, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com