A kind of amino modified tio 2 Preparation method of leather fiber

A leather fiber, amino modification technology, applied in the direction of light-resistant fiber, fiber treatment, textile and papermaking, etc., can solve the problem of aging of the coating agent, and achieve increased rubbing fastness, good UV resistance, and strong stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides an amino modified TiO 2 The preparation method of leather fiber includes the following steps:

[0016] 1) Use silane coupling agent (3-aminopropyltriethoxysilane) to TiO 2 Carry out surface chemical modification to make TiO 2 With amino groups on the surface: 3-5g TiO 2 Add 0.5-1% silane coupling agent in volume fraction, mix and stir for 2-3h, control the temperature at 60-80℃, after the reaction, filter and dry at 110℃ for 10-20min.

[0017] 2) Use sodium chloroacetate to carboxylate the leather fiber, so that the leather fiber has more active groups:

[0018] 2.1) Add 20-30g of chloroacetic acid and 15-20mL of water to a three-necked flask, stir to dissolve, and at the same time add 30-50% sodium hydroxide solution to neutralize to obtain sodium chloroacetate;

[0019] 2.2) Soak 3-5g leather in 100-200mL deionized water, soak for 10-12h, and then place it in a water bath constant temperature oscillator to shake for 4-6h;

[0020] 2.3) Add the sodium chlo...

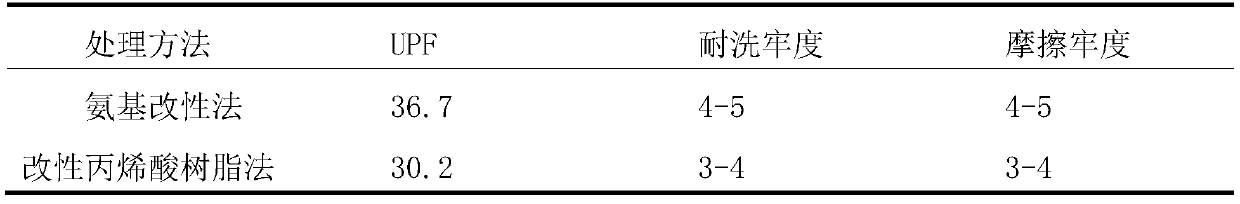

Embodiment 1

[0027] (1) 3g TiO 2 A silane coupling agent with a volume fraction of 0.5% was added, mixed and stirred for 3 hours, and the temperature was controlled at 60°C. After the reaction, it was filtered and dried at 110°C for 15 minutes.

[0028] (2) Add 20 g of chloroacetic acid and 15 mL of water into a three-necked flask, stir to dissolve, and simultaneously add 30% sodium hydroxide solution to neutralize to obtain sodium chloroacetate. Then 3g leather was immersed in 100mL deionized water for 10h, and then placed in a water bath constant temperature shaker for 4h. Add sodium chloroacetate to the wet leather for reaction, the temperature is 45 ℃, with NaHCO 3 Adjust the pH value of the system to remain at 7.5, and react for 6 hours.

[0029] (3) Put the product prepared in (1) and (2) above in a 100 mL beaker, add 0.05 g / mL zirconium sulfate solution, the pH of the system is 1.5, and stir and react for 3 hours. After the reaction, it was filtered, washed with deionized water 5 times,...

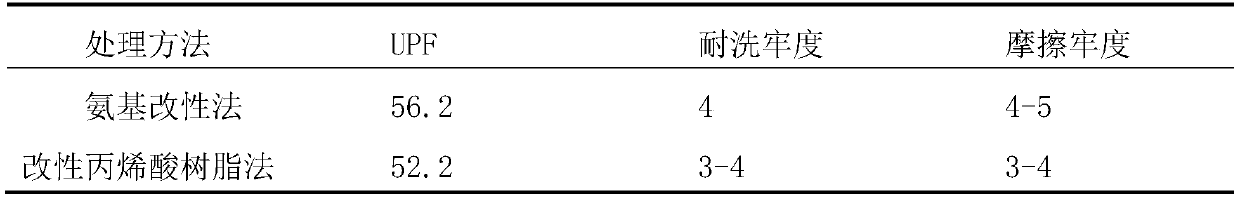

Embodiment 2

[0036] (1) Put 5g TiO 2 Add a silane coupling agent with a volume fraction of 1%, mix and stir for 3 hours, and control the temperature at 60°C. After the reaction, filter and dry at 110°C for 15 minutes.

[0037] (2) Add 22 g of chloroacetic acid and 15 mL of water to a three-necked flask, stir to dissolve, and at the same time add 30% sodium hydroxide solution to neutralize to obtain sodium chloroacetate. Then 3g leather was immersed in 100mL deionized water for 10h, and then placed in a water bath constant temperature shaker for 4h. Add sodium chloroacetate to the wet leather for reaction, the temperature is 45 ℃, with NaHCO 3 Adjust the pH value of the system to keep at 8, and react for 6 hours.

[0038] (3) Put the product prepared in (1) and (2) above in a 100 mL beaker, add 0.07 g / mL zirconium sulfate solution, the system pH is 1.5, and stir for 4 hours. After the reaction, it was filtered, washed with deionized water 5 times, and dried.

[0039] (4) Homemade containing 5g T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com