Small energy-saving and efficient domestic garbage incinerating treatment system

A domestic waste incineration and treatment system technology, which is applied in the field of small-scale energy-saving and high-efficiency domestic waste incineration treatment systems, can solve the problems of insufficient use of waste heat from flue gas, expensive crushing machinery, and high energy consumption for dehydration, and achieves simple structure and low manufacturing cost. Low cost, easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

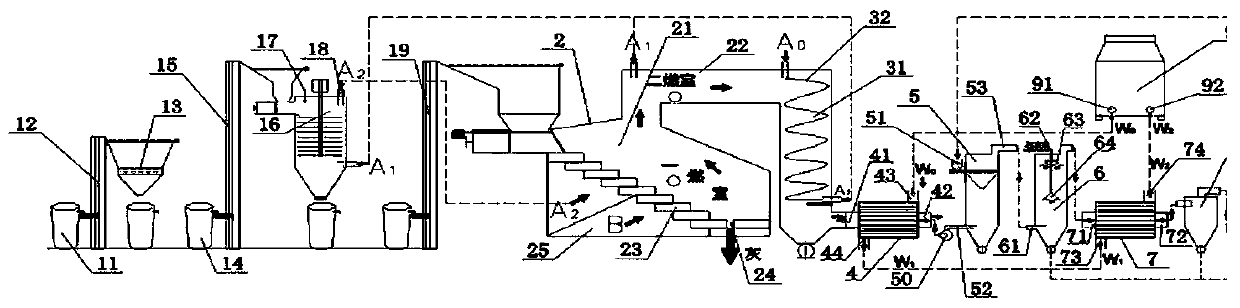

[0038] Embodiment one: if figure 1 As shown, the present invention is a small-scale energy-saving and high-efficiency domestic waste incineration treatment system, including a pre-incineration treatment system, an incineration system, a flue gas waste heat utilization device, and a flue gas treatment system. The flue gas treatment system includes a first gas-liquid heat exchange device 4 , the first induced draft fan 50, the excess alkali ash utilization tower 5, the semi-dry deacidification tower 6, the second gas-liquid heat exchange device 7, the cooling water tower 9, the cyclone dust collector 81, the bag filter 82, the second induced draft fan 83 and chimney 84.

[0039] The pre-incineration treatment system of this embodiment includes a domestic waste crushing device and a vertical rotary garbage drying device independently arranged; the domestic waste crushing device includes a first garbage can 11, a first garbage self-loading and unloading device 12 and a crusher dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com