Development method for determining copper smelting slag multi-element standard sample through X-ray fluorescence spectrometry

A technology for X-ray fluorescence spectroscopy and copper smelting slag is applied in the field of research and development of multi-element standard samples in the determination of copper smelting slag by X-ray fluorescence spectroscopy. The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

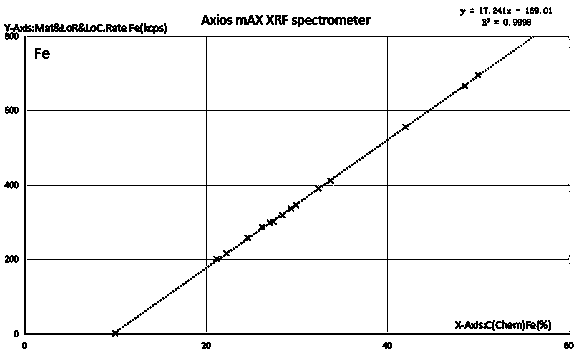

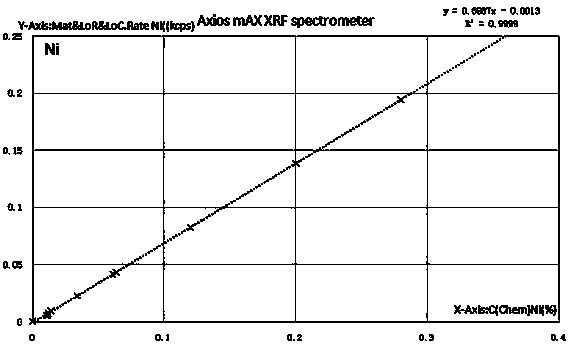

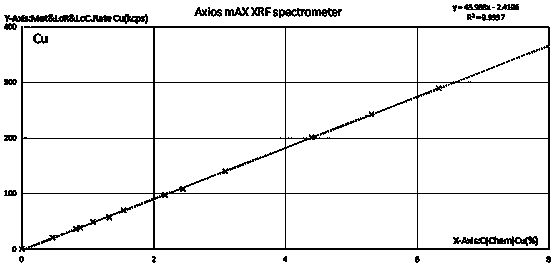

Image

Examples

Embodiment

[0032] Embodiment: a specific embodiment of the present invention is as follows:

[0033] A) Standard sample preparation method: use the copper smelting production slag from a company’s existing analysis results as the original material, and finally determine 13 slag samples of different grades as the standard sample after setting the composition. Put the 13 samples and the sub-samples preserved in the production into the ball mill, grind and mix them → pass through a 150-mesh (﹤0.106mm) sieve → fully mix them again, then divide them into 10 parts, and put them in the container respectively in a glass bottle.

[0034] B) Uniformity inspection: A) the samples contained in glass bottles, measure Cu, Fe, SiO for each bottle sample 2 , CaO, MgO, Al 2 o 3 Content, repeated measurement twice, using the variance F test method, test results: F α(0.05) , the sample uniformity is good. Inspection method: copper, iron, silicon dioxide-titration method; calcium oxide, magnesium oxide,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com