Preparation method of immunohistochemical detecting section

A technique of immunohistochemistry and tissue slicing, which is applied in the field of preparation of immunohistochemical detection slices, which can solve the problems of difficulty in satisfying diversity detection and the complexity of slice production, and achieve the effects of avoiding reagent evaporation, reducing reagent consumption, and easy humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing immunohistochemical detection slices, comprising the following steps:

[0031] Step 1: Obtain a paraffin section of the breast tissue sample to be tested, and spread the paraffin section on a polyimide plastic film (commercially available, with a tolerance temperature of 400°C and an embrittlement temperature of minus 200°C), and paraffin section Tightly adhere to the plastic film to form a paraffin section attached to the plastic film, and bake the slice at 60°C for 30 minutes after rolling; the thickness of the polyimide plastic film used in this step is 30 μm; the rolling method described in this step is to use The rubber roller rolls back and forth on the paraffin section of breast cancer;

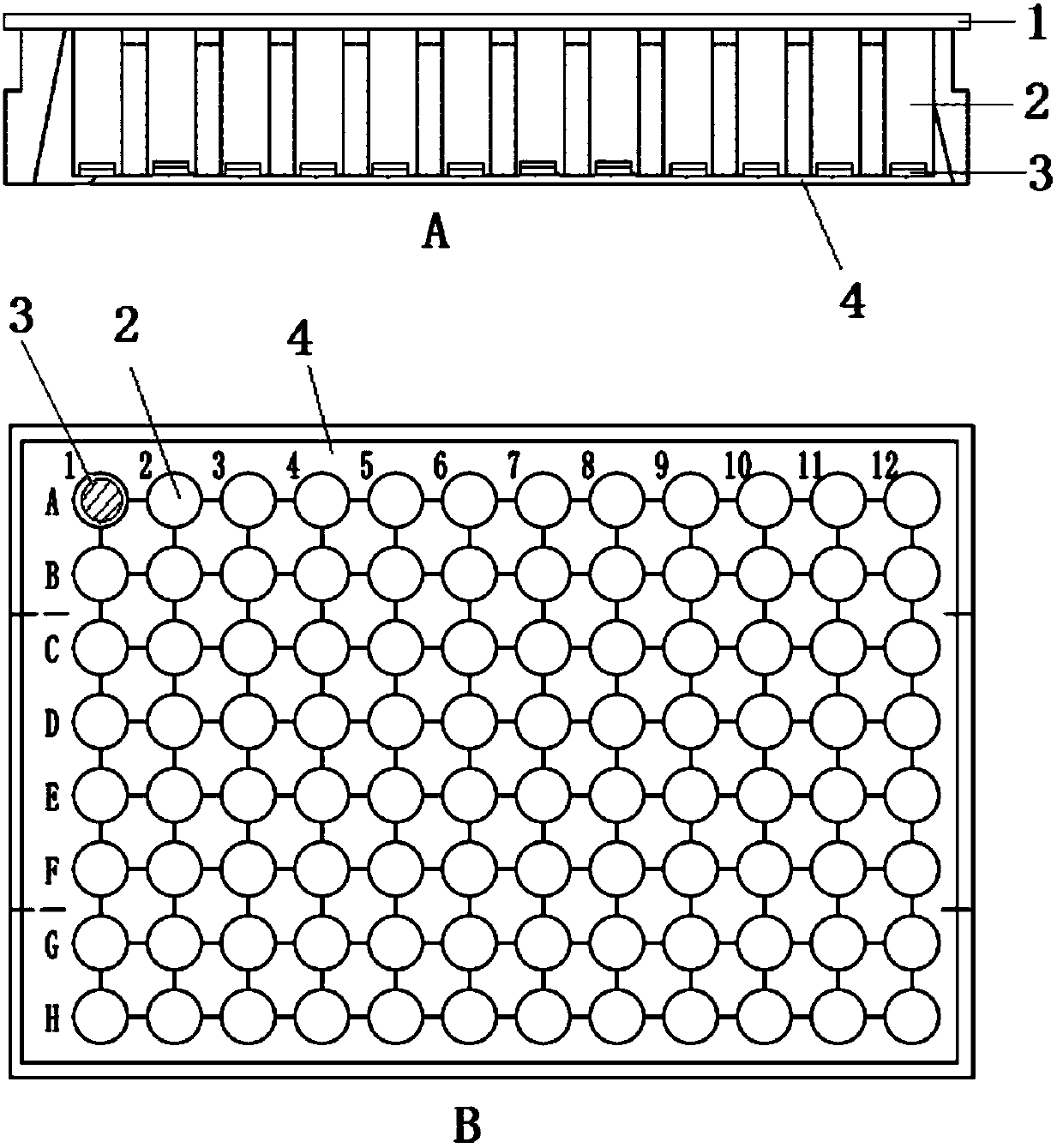

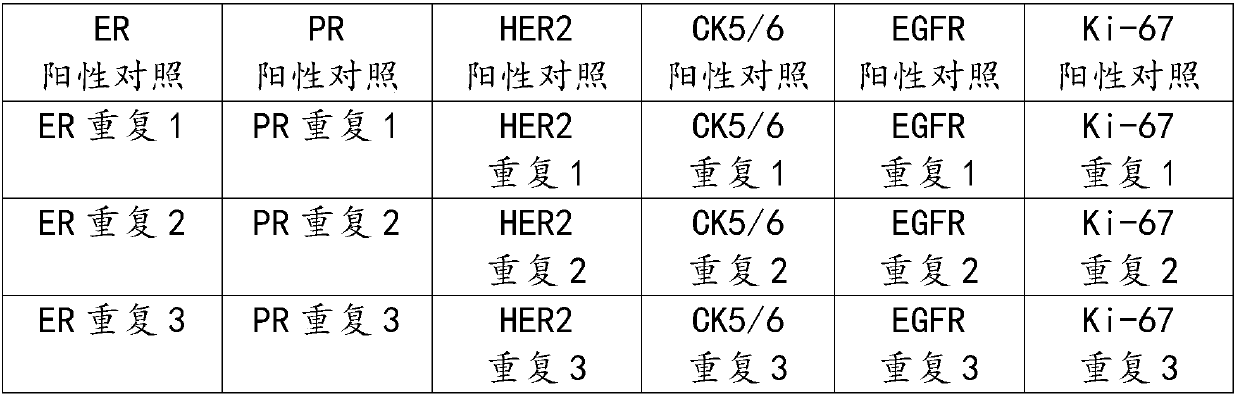

[0032] Step 2, punching the obtained paraffin section attached with a plastic film to obtain 18 (6 treatments in total, each treatment repeated 3 times) circular paraffin section attached with a plastic film whose diameter is 3mm; ...

Embodiment 2

[0049] This embodiment is a modification of Embodiment 1. Compared with Embodiment 1, the only changes are:

[0050] In step 1, the plastic film is selected polynaphthyl ester plastic film (commercially available, the tolerance temperature is 265 ℃, and the brittle temperature is lower than minus 196 ℃), the baking sheet temperature is 65 ℃, and the thickness of the polyester plastic film is 250 μm; this step The flattening method is to use a glass rod to roll back and forth on the paraffin section of breast cancer;

[0051] In step 2, the obtained paraffin section attached with a plastic film is punched to obtain a circular paraffin section attached with a plastic film with a diameter of 20 mm.

[0052] In this example, four six-well plates were used for immunofluorescent staining.

[0053] In the process of preparing 100 tissue sections according to the tissue section preparation method provided in this example, only 5 tissue sections had the plastic film fall off during th...

Embodiment 3

[0055] This embodiment is an improved example of embodiment 1. Compared with embodiment 1, the improvements only lie in:

[0056] In step 1, the plastic film is also subjected to the following pretreatment: first, the surface of the plastic film is coated with a mixture of egg white and anionic polyelectrolyte aqueous solution (the mass concentration of the aqueous solution is 0.5%) at a volume ratio of 5:2. drying, and then coating a cationic polyelectrolyte solution (the mass concentration of the aqueous solution is 0.5%) on the surface of the plastic film pre-laid paraffin section and drying, wherein the anionic polyelectrolyte is polyacrylic acid, and the cationic polyelectrolyte is polyvinylamine. The drying described in this example is air drying.

[0057] In this example, the above-mentioned pretreatment of the plastic film can not only improve the firmness of the combination of the tissue section and the plastic film, but also the plastic film has good hydrophilic prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Temperature tolerance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com