Polyvinyl chloride cable material with excellent flame-retardant property and preparation method thereof

A polyvinyl chloride cable, flame retardant technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of flammability, low oxygen index, etc., achieve long service life, good aging resistance, The effect of reducing the economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

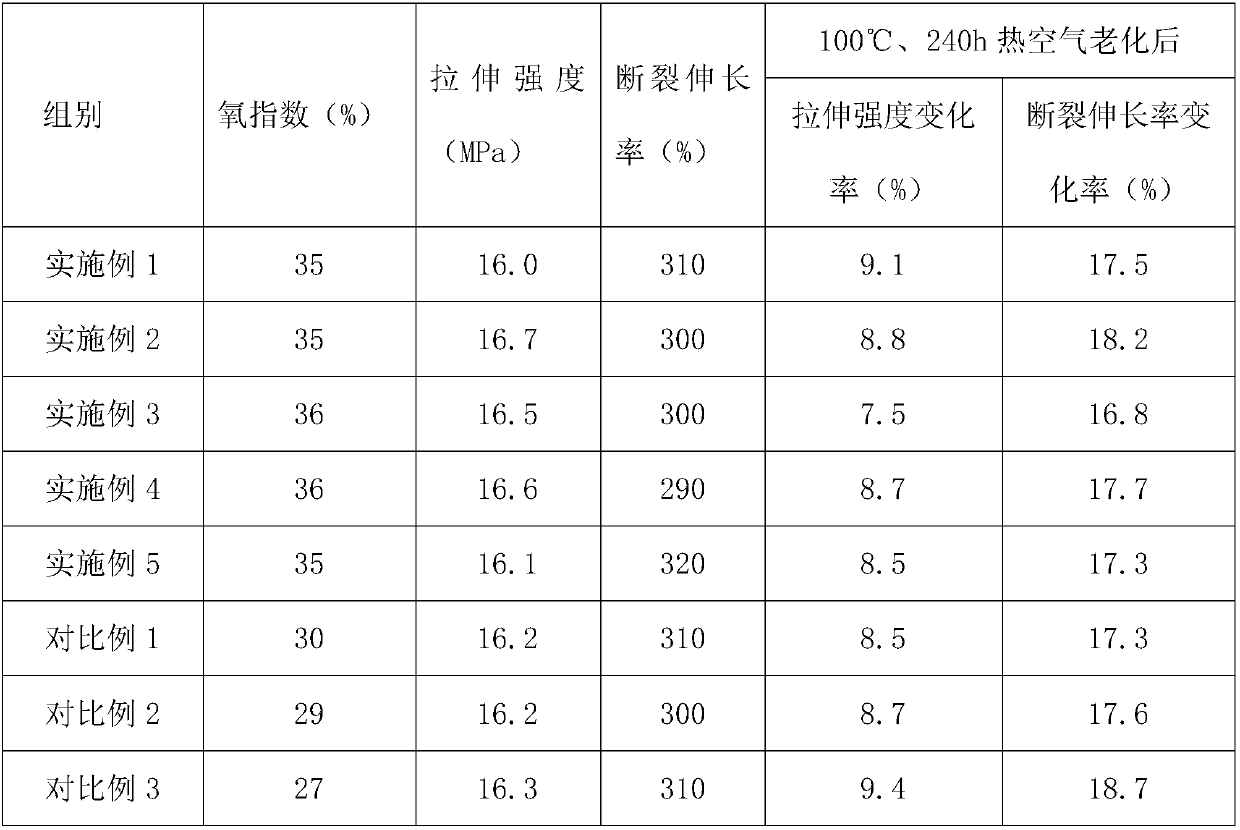

Examples

Embodiment 1

[0026] A polyvinyl chloride cable material with excellent flame retardancy, made of the following raw materials in parts by weight: 110 parts of PVC resin, 8 parts of dioctyl phthalate, 15 parts of light calcium carbonate, and 3 parts of fumed white carbon black 1 part, 1 part of turpentine, 0.5 part of dicumyl peroxide, 2 parts of antioxidant, 0.4 part of antioxidant, 1 part of p-hydroxybenzophenone, 2 parts of titanium dioxide, 1 part of barium stearate, 4 parts of antimony oxide parts, mullite 7 parts, titanium aluminum carbide 2 parts.

[0027] Wherein, the anti-aging agent is composed of anti-aging agent CPPD and anti-aging agent AW according to the weight ratio of 2:3; the antioxidant is antioxidant 1076.

[0028] In this embodiment, the preparation method of the polyvinyl chloride cable material with excellent flame retardant properties, the steps are as follows:

[0029] 1) Take mullite by weighing, after pulverizing, pass through a 60-mesh sieve to obtain mullite pow...

Embodiment 2

[0037] A polyvinyl chloride cable material with excellent flame retardancy, made of the following raw materials in parts by weight: 113 parts of PVC resin, 9 parts of dioctyl phthalate, 16 parts of light calcium carbonate, and 5 parts of fumed white carbon black 1.8 parts of turpentine, 0.8 parts of dicumyl peroxide, 2.3 parts of antioxidant, 0.5 parts of antioxidant, 1.4 parts of p-hydroxybenzophenone, 2.3 parts of titanium dioxide, 1.8 parts of barium stearate, 5.5 parts of antimony oxide parts, mullite 8.5 parts, titanium aluminum carbide 3.5 parts.

[0038] Wherein, the anti-aging agent is composed of anti-aging agent CPPD and anti-aging agent AW according to the weight ratio of 2:3; the antioxidant is antioxidant 1076.

[0039] In this embodiment, the preparation method of the polyvinyl chloride cable material with excellent flame retardant properties, the steps are as follows:

[0040] 1) take mullite, after pulverizing, cross 80 mesh sieves, obtain mullite powder;

[...

Embodiment 3

[0048] A polyvinyl chloride cable material with excellent flame retardancy, made of the following raw materials in parts by weight: 115 parts of PVC resin, 10 parts of dioctyl phthalate, 17 parts of light calcium carbonate, and 5 parts of fumed white carbon black 1.4 parts of turpentine, 0.7 parts of dicumyl peroxide, 2.5 parts of antioxidant, 0.6 parts of antioxidant, 1.5 parts of p-hydroxybenzophenone, 2.6 parts of titanium dioxide, 1.4 parts of barium stearate, 5 parts of antimony oxide parts, mullite 8 parts, titanium aluminum carbide 3 parts.

[0049] Wherein, the anti-aging agent is composed of anti-aging agent CPPD and anti-aging agent AW according to the weight ratio of 2:3; the antioxidant is antioxidant 1076.

[0050] In this embodiment, the preparation method of the polyvinyl chloride cable material with excellent flame retardant properties, the steps are as follows:

[0051] 1) take mullite, after pulverizing, cross 80 mesh sieves, obtain mullite powder;

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com