PE-ABS (polyethylene-acrylonitrile-butadiene-styrene) alloy and preparation method thereof

A technology of PE-ABS and ABS resin, applied in the field of PE-ABS alloy and its preparation, can solve the problems of low strength and poor wear resistance, and achieve the effects of low processing cost, excellent comprehensive performance and prolonged service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

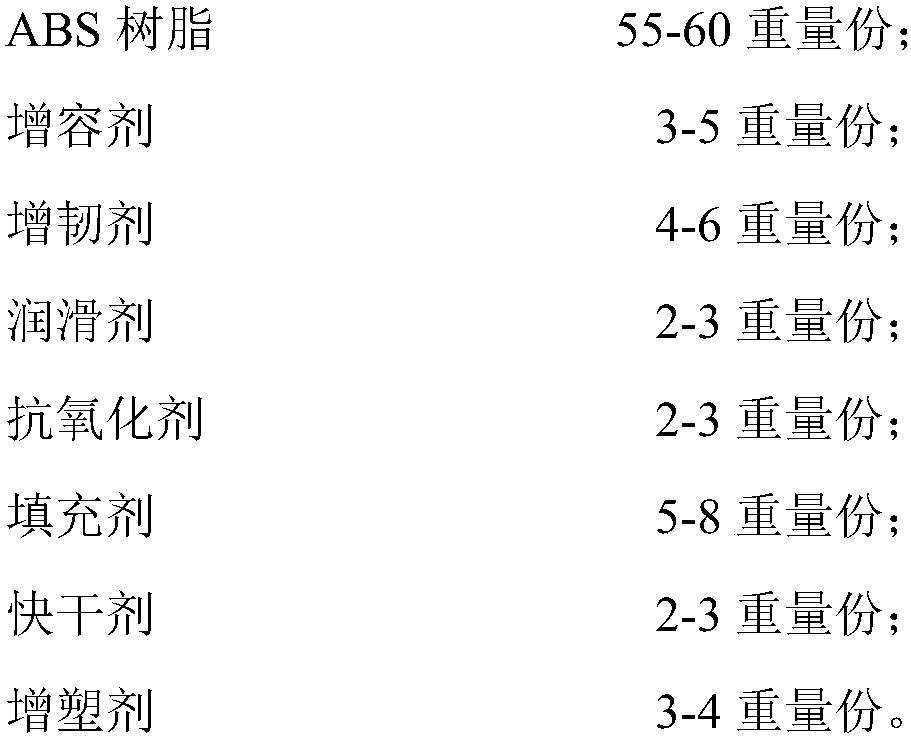

[0039] A PE-ABS alloy consisting of the following components:

[0040]

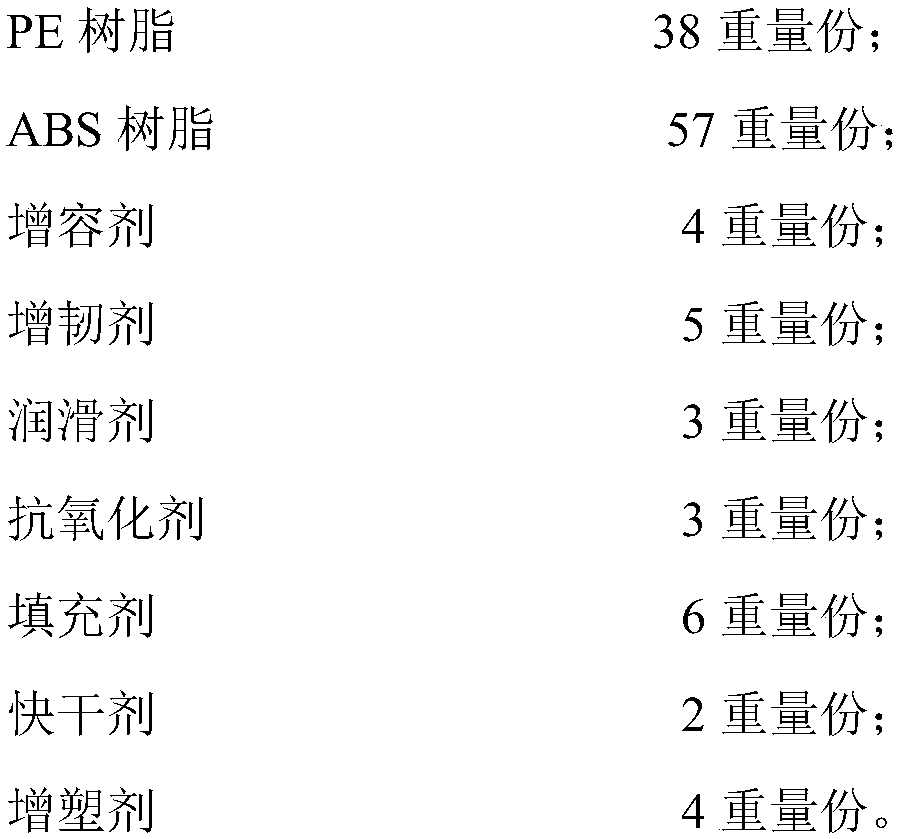

[0041] Specifically, it consists of the following components:

[0042]

[0043] Specifically, the compatibilizer is styrene-acrylonitrile-glycidyl methacrylate, ethylene-glycidyl ester, ethylene-propylene n-butyl ester-glycidyl ester and / or maleic anhydride grafted acrylonitrile- at least one of butadiene-styrene copolymers.

[0044] Specifically, the toughening agent is polyolefin.

[0045] Specifically, the lubricant is at least one of magnesium stearate, calcium stearate and / or polysiloxane.

[0046] Specifically, the antioxidant is at least one of 2-hydroxy-4-n-octyloxybenzophenone, sodium ethylparaben, sodium D-isoascorbate and / or ascorbyl palmitate.

[0047] Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com