Lossless plugging agent based on inorganic silicate and preparation and construction methods of lossless plugging agent

A technology of inorganic silicate and plugging agent, which is applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low strength, uneven gel, short service life, etc., and achieves high strength, gel Uniform, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

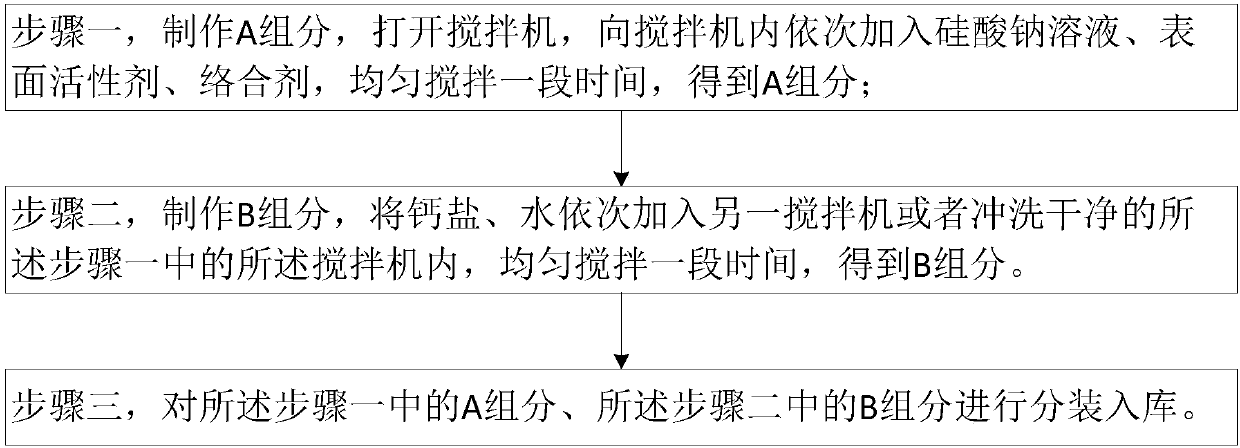

[0034] Such as figure 1 Shown, the preparation method of the nondestructive plugging agent based on inorganic silicate comprises the steps:

[0035] Step 1: Make component A, turn on the mixer, add sodium silicate solution, surfactant, and complexing agent to the mixer in sequence, and stir evenly for a period of time to obtain component A;

[0036] Step 2, making component B, adding calcium salt and water in turn to another blender or the mixer in step 1 that has been rinsed, and stirring evenly for a period of time to obtain component B.

[0037] Preferably, in the above-mentioned preparation method of non-destructive lost circulation plugging agent based on inorganic silicate, it also includes: step 3, distributing component A in step 1 and component B in step 2 into storage.

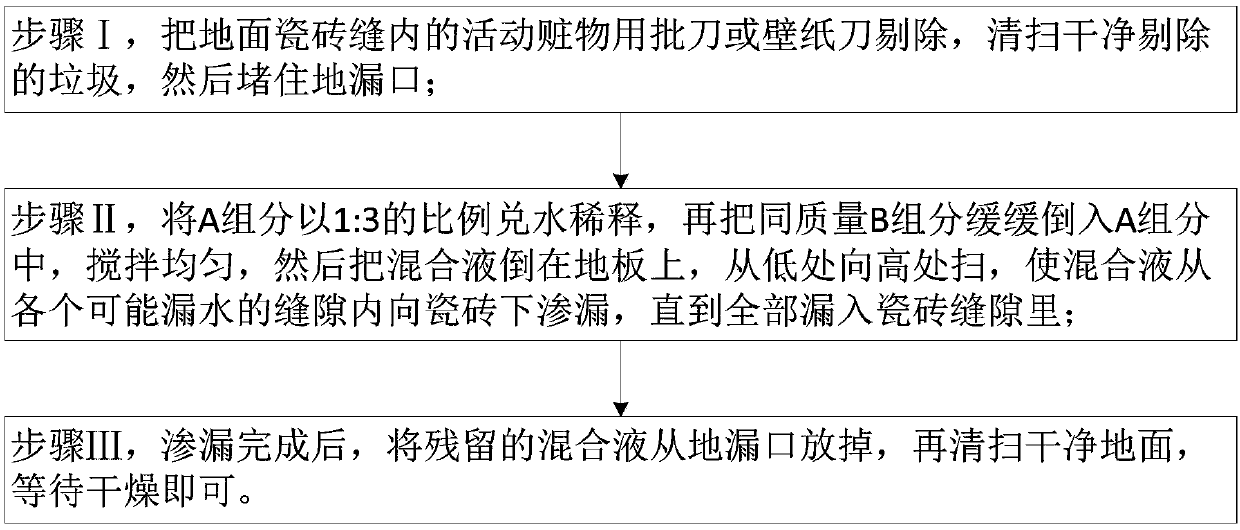

[0038] figure 2 It is a flowchart of the construction method of the non-destructive plugging agent based on inorganic silicate of the present invention;

[0039] Such as figure 2 As shown, the ...

Embodiment 1

[0044] Embodiment 1: (A component: sodium silicate solution 90%, sodium dodecylbenzene sulfonate 1%, EDTA9%; B component: concentration is the calcium nitrate solution 100% of 5%)

[0045] Preparation of component A: measure by weight, take 90kg of sodium silicate solution, 1kg of sodium dodecylbenzene sulfonate, and 9kg of EDTA, and slowly add them to the started mixer in turn. After all the materials are added, stir evenly for 30 Minutes, shut down, put into warehouse, obtain about 100kg of A component.

[0046] Preparation of component B: measure by weight, take 5kg of calcium nitrate and 95kg of water, and slowly add them into the started mixer in turn. After all the materials are added, stir evenly for 30 minutes, stop the machine, put them into the warehouse, and get B The components are about 100kg.

[0047]Then, use a batch knife or a wallpaper knife to remove the movable spoils in the joints of the floor tiles, clean up the ground garbage, and then block the floor dr...

Embodiment 2

[0048] Embodiment 2: (A component: potassium silicate solution 88%, sodium dodecylbenzenesulfonate 1%, EDTA-4Na11%; B component: concentration is 8% calcium chloride solution 100%)

[0049] Preparation of component A: measure by weight, take 88kg of potassium silicate solution, 1kg of sodium dodecylbenzenesulfonate, and 11kg of EDTA-4Na, and slowly add them to the started mixer in sequence. Stir for 1 hour, stop the machine, put it into storage, and obtain about 100kg of component A.

[0050] Preparation of component B: measure by weight, take 8kg of calcium chloride and 92kg of water, and slowly add them into the started mixer in turn. After all the materials are added, stir evenly for 1 hour, stop the machine, put them into the warehouse, and get B The components are about 100kg.

[0051] Then, use a batch knife or a wallpaper knife to remove the movable spoils in the joints of the floor tiles, clean up the ground garbage, and then block the floor drain; take 5kg of compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com