Non-scintillation core-shell structure quantum dot and preparation method thereof

A core-shell structure and quantum dot technology, applied in the field of non-scintillation core-shell structure quantum dots and their preparation, can solve the problems of reduced device efficiency, unstable luminescence, loss of tracer targets, etc., and achieves uniform size distribution and stable fluorescence performance. , the effect of good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing quantum dots with a non-blinking core-shell structure described in the above technical solution, comprising the following steps:

[0037] (1) mixing cadmium source, zinc source, fatty acid and phosphorus-free organic solvent, heating under anaerobic conditions to obtain cadmium and zinc mixed solution;

[0038] (2) Under anaerobic conditions, the mixed solution of elemental selenium and sulfur source is injected into the mixed solution of cadmium and zinc, and a nucleation reaction is carried out to obtain a compound containing Zn x Cd 1-x Se y S 1-y nucleosome mixture;

[0039] (3) under anaerobic conditions, the mixed solution of sulfur source and zinc source is added dropwise to the mixed solution obtained in the step (2), and the shell growth reaction is carried out to obtain non-scintillation core-shell structure quantum dots;

[0040] In the mixed solution of the sulfur source and the zinc source, the ...

Embodiment 1

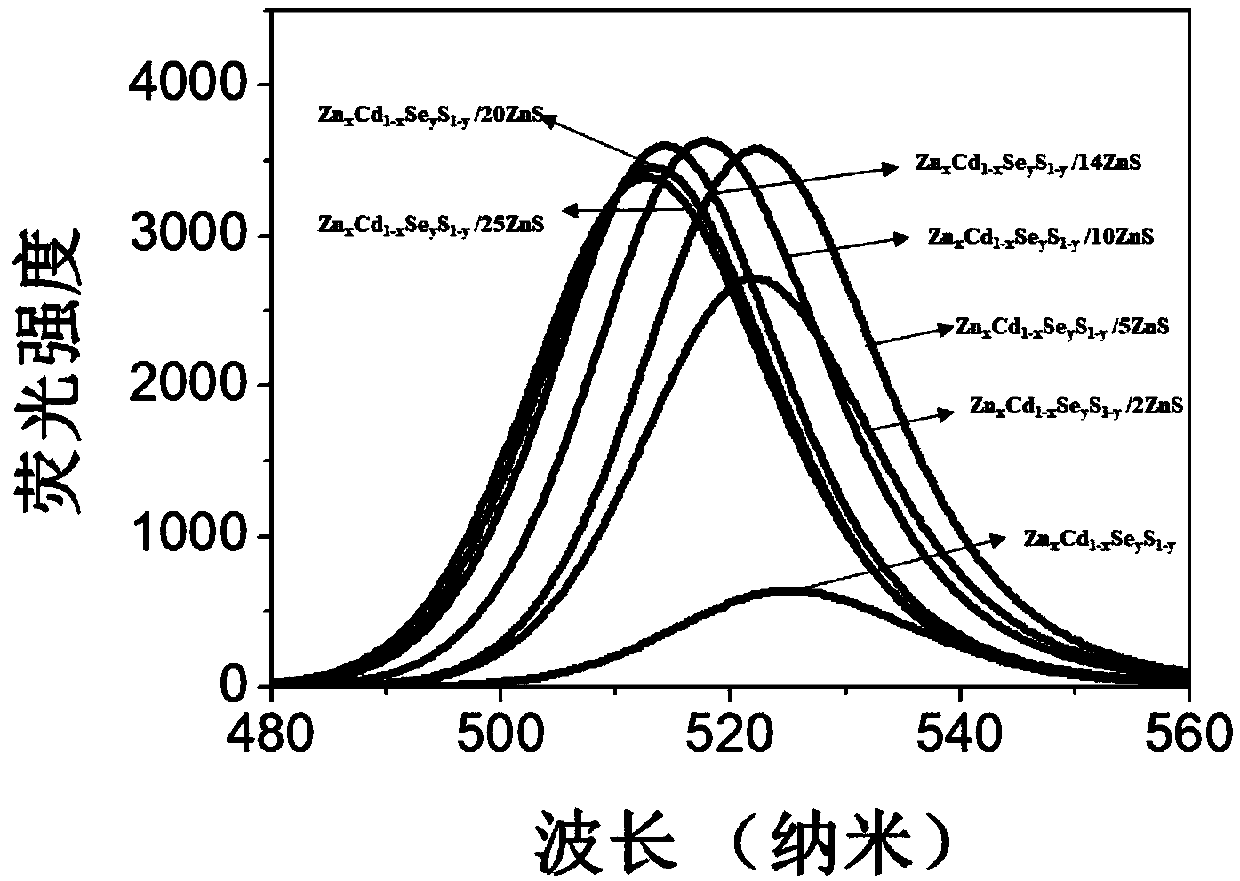

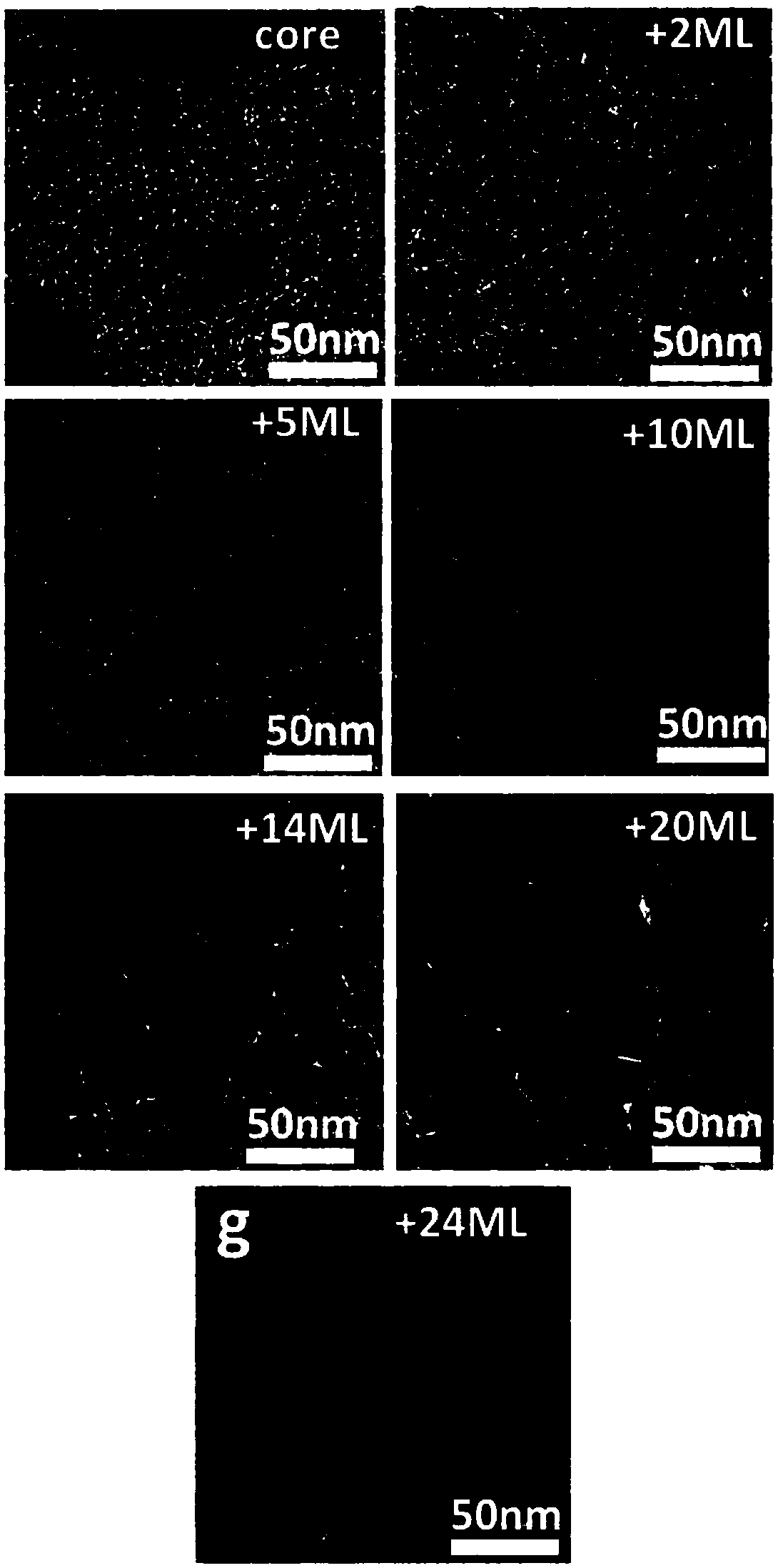

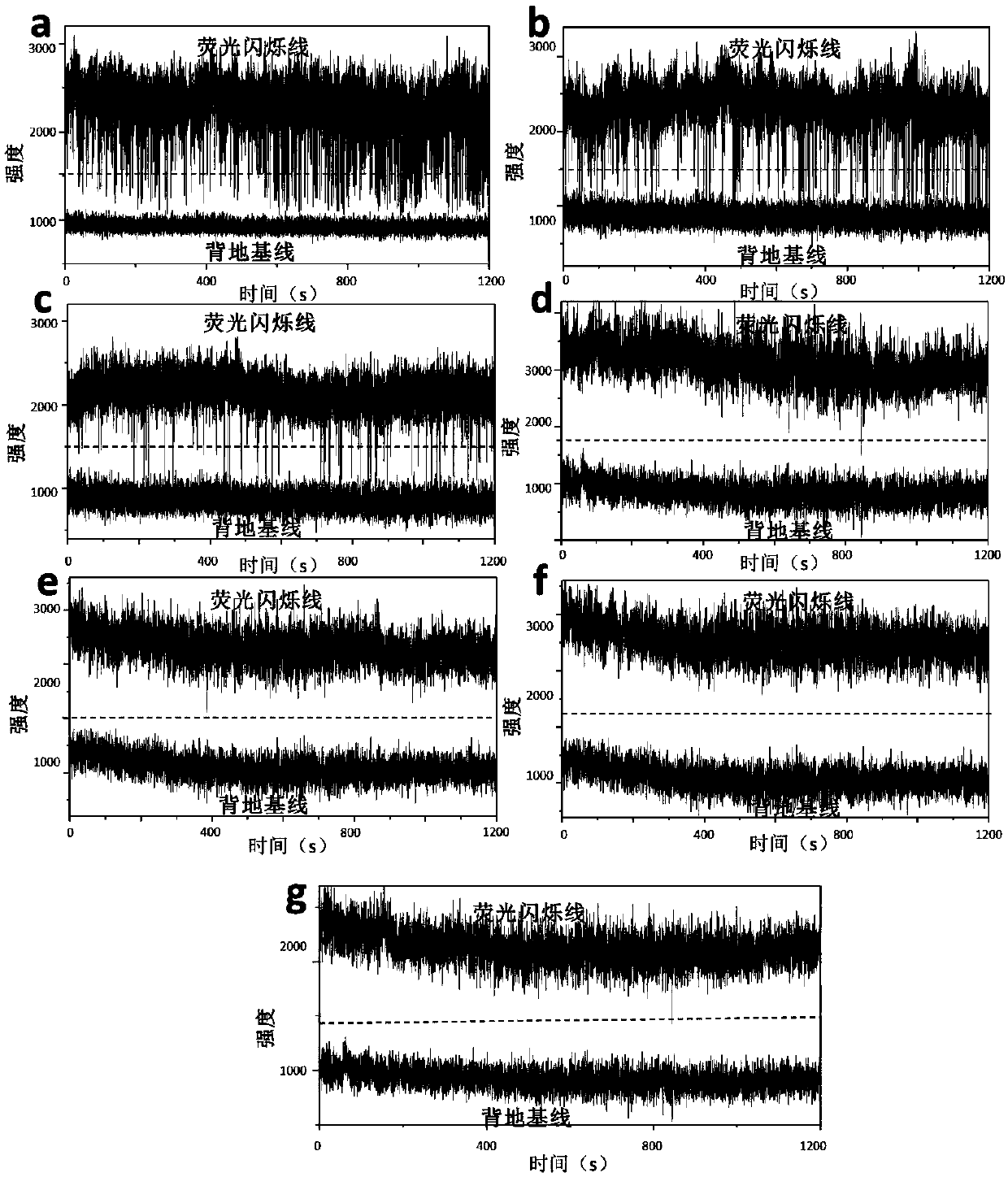

[0059] Take 0.4mmol of zinc acetate, 0.1mmol of cadmium oleate, 2mmol of oleic acid and 20mL of liquid paraffin, mix them, raise the temperature to 290°C at a rate of 15°C / min under nitrogen protection, inject 0.25mmol of Se powder and 0.02mmol of octane mercaptan Mix the solution and react at 290°C for 30 minutes to obtain Zn-containing 0.8 Cd 0.2 Se 0.5 S 0.5A mixed solution of quaternary alloy quantum dot nuclei. Keep the crystal nucleus mixed solution at 290°C, drop the octadecene solution of zinc oleate and octaalkylmercaptan into the crystal nucleus mixed solution, the total volume is 60 ml; drop zinc oleate and octadecyl mercaptan according to the molar ratio of 1:1.5 Alkyl mercaptans were added dropwise with 30mmol zinc oleate and 45mmol octaalkyl mercaptans at a rate of 6mL / h, and Zn with different shell thicknesses were obtained at different times. 0.8 Cd 0.2 Se 0.5 S 0.5 / ZnS non-blinking core-shell quantum dots, with a total of 25 layers.

[0060] The corre...

Embodiment 2

[0066] Take 0.45mmol of zinc acetate, 0.05mmol of cadmium oleate, 2mmol of oleic acid and 20mL of liquid paraffin to mix, gradually raise the temperature to 280°C at a rate of 15°C / min under nitrogen protection, inject 0.15mmol of Se powder and 0.4mmol of hexaalkyl bidentate A mixed solution of mercaptans, followed by reaction at 280°C for 30min, to obtain Zn-containing 0.9 Cd 0.1 Se 0.3 S 0.8 A mixed solution of quaternary alloy quantum dot nuclei. Keep the crystal nucleus mixture at 280°C, drop zinc oleate and hexaalkyl bidentate mercaptan octadecene solution into the crystal nucleus mixture, with a total volume of 30 ml; drop zinc oleate in a molar ratio of 1:1.5 and hexaalkyl tridentate mercaptan, the total amount of dripping is 15mmol of zinc oleate, hexaalkyl tridentate mercaptan is 22.5mmol, and the rate of addition is 6mL / h, and Zn is obtained after 120min. 0.9 Cd 0.1 Se 0.3 S 0.8 / ZnS non-blinking core-shell quantum dots, with a total of 16 layers.

[0067] Te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com