Smart type autonomous underwater vehicle (AUV) shell structure and preparation method thereof

A shell structure, intelligent technology, applied in the direction of chemical instruments and methods, underwater operation equipment, synthetic resin layered products, etc., can solve the problems of large metals, complex level restrictions, complex mechanical force requirements, etc., to achieve good results Effects of pressure resistance, ensuring safety and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] On the other hand, the present invention also provides a method for preparing the above-mentioned intelligent AUV shell structure, including:

[0041] Step 1: Preparation of the rigid layer: The rigid layer of the multi-dimensional hybrid fiber reinforced resin composite material is prepared by using the three-dimensional woven prefabricated fabric structure, and the optical fiber hybrid is selected as the intelligent sensing component in the hybrid multi-dimensional fabric. After the surface weaving is completed, the impregnation is carried out by vacuum introduction of the resin matrix. The vacuum degree during the impregnation process is controlled at 0.06-0.1MPa. After the impregnation is completed, the rigid layer is finally formed by thermosetting molding. The resin matrix content of the rigid layer of the material is controlled between 20% and 40%;

[0042]Step 2: Preparation of reinforcement layer: The surface of the rigid layer obtained in step 1 is prepared by...

Embodiment 1

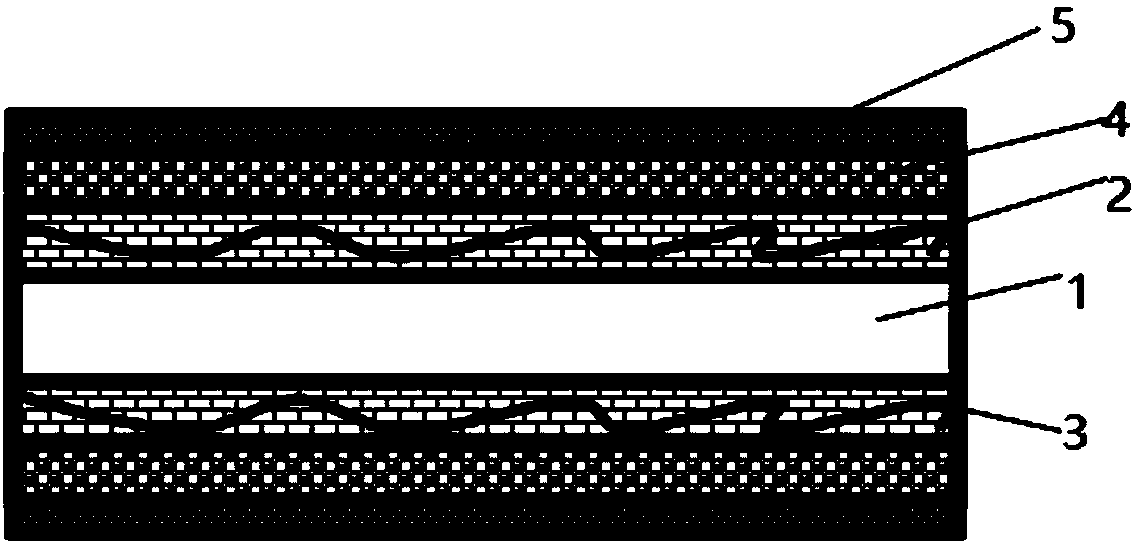

[0047] The shell structure of the specific embodiment of the present invention is composed of a metal airtight cavity, a rigid layer of multi-dimensional hybrid fiber reinforced resin matrix composite material, a reinforced layer of two-dimensional wound hybrid fiber reinforced resin matrix composite material, and a multi-dimensional carbon fiber reinforcement of the outermost layer from the inside to the outside. Composition of anti-seepage layer of rubber matrix;

[0048] The innermost layer is an aluminum alloy cylindrical cavity with a diameter of 10cm and a length of 1 meter;

[0049] The rigid layer of multi-dimensional hybrid fiber-reinforced resin matrix composites was prepared by using a three-dimensional four-way fabric structure. The hybrid fabric uses T300 carbon fiber as the main fiber and alumina as the auxiliary fiber. The ratio of carbon fiber and auxiliary fiber is 10:1. In the hybrid multi-dimensional fabric The high-conductivity glass fiber hybrid of 8-10μm ...

Embodiment 2

[0053] The shell structure of the specific embodiment of the present invention is composed of a metal airtight cavity, a rigid layer of multi-dimensional hybrid fiber reinforced resin matrix composite material, a reinforced layer of two-dimensional wound hybrid fiber reinforced resin matrix composite material, and a multi-dimensional carbon fiber reinforcement of the outermost layer from the inside to the outside. Composition of anti-seepage layer of rubber matrix;

[0054] The innermost layer is a titanium alloy cylindrical cavity with a diameter of 50 cm and a length of 5 meters;

[0055] The rigid layer of multi-dimensional hybrid fiber-reinforced resin-based composites was prepared by using a three-dimensional five-directional fabric structure. The hybrid fabric uses T800 carbon fiber as the main fiber and glass fiber as the auxiliary fiber. The ratio of carbon fiber and auxiliary fiber is 1:1. In the hybrid multi-dimensional fabric The high-conductivity glass fiber hybrid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com