High-temperature-resistance PVC wood-plastic composite material and preparation method thereof

A wood-plastic composite material and high-temperature-resistant technology, which is applied in the field of PVC wood-plastic materials, can solve the problems of light weight, impact resistance, high-temperature resistance and flame retardancy, unfavorable market promotion, high material weight, etc., and achieves low preparation cost and low raw material Wide range of sources, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

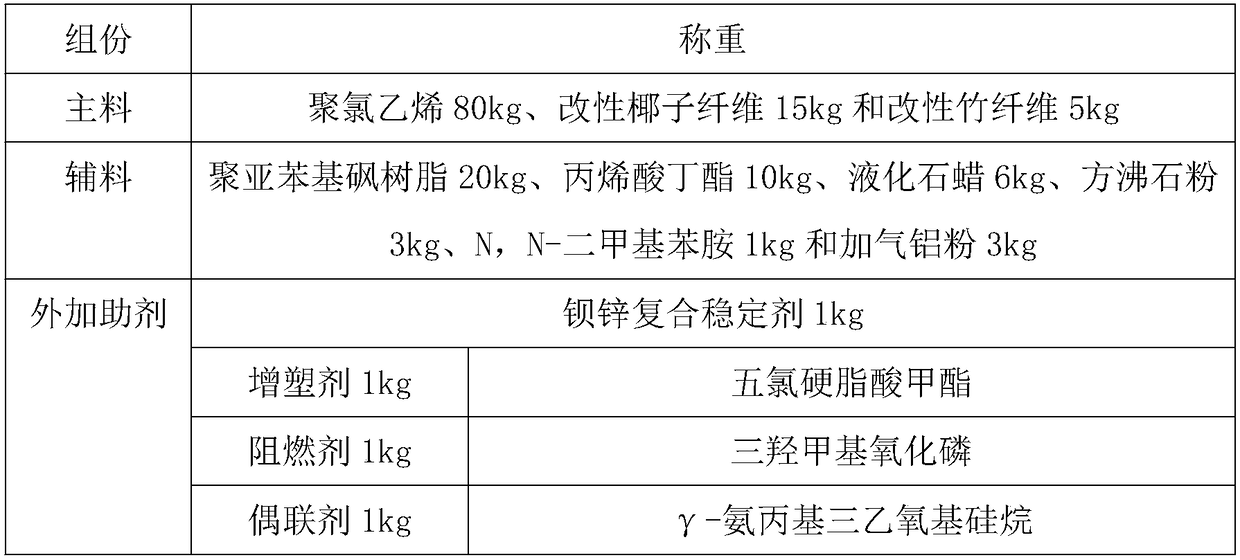

[0022] A high temperature-resistant PVC wood-plastic composite material is prepared by weighing the raw materials in the following table 1:

[0023] Table 1

[0024]

[0025] The above-mentioned modified coconut fiber is obtained through the following steps: take 15 kg of coconut fiber and place it in a grinder to grind until the fiber length is less than or equal to 100 μm, and the aspect ratio is less than 10; after the grinding treatment, use an acrylic acid copolymer with a temperature of 45 ° C to grind The last coconut fiber is soaked for 6h; then the coconut fiber after soaking is coated with low-carbon polyhydric alcohol with a temperature of 45°C, and the bulk density of the coconut fiber is controlled at 2.0g / cm 3 Below, promptly make the required modified coconut fiber of raw material of the present invention;

[0026] The above-mentioned modified bamboo fiber is obtained through the following steps: adding water to 5kg of bamboo fiber to adjust the water conten...

Embodiment 2

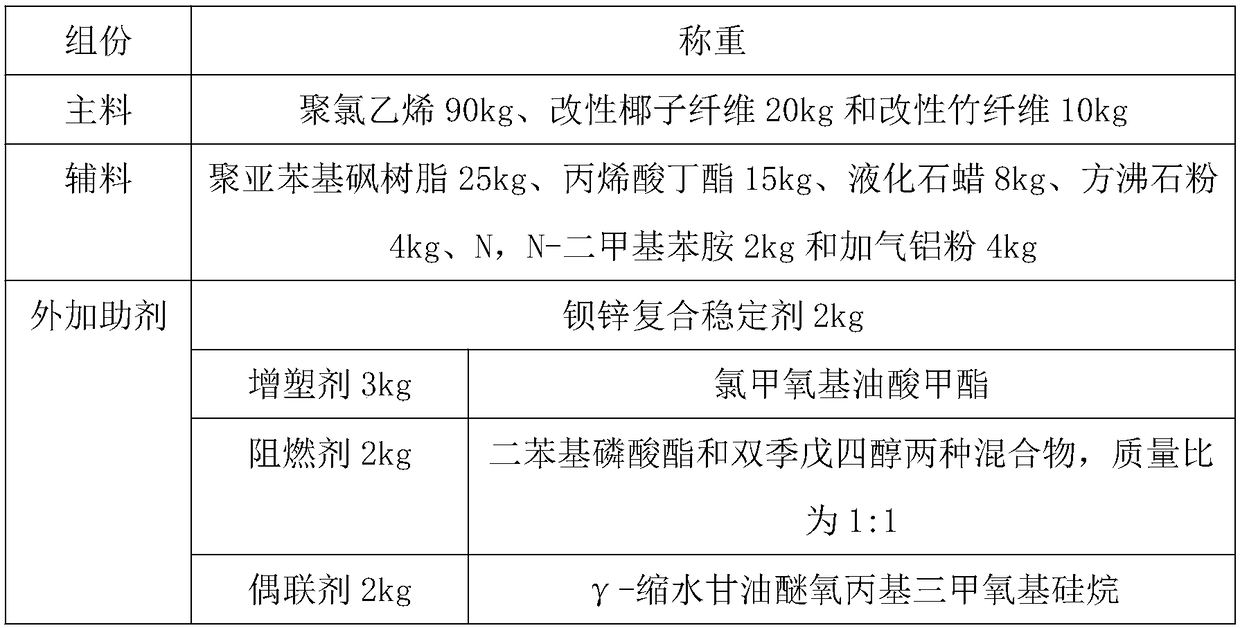

[0032] A kind of high temperature resistant PVC wood-plastic composite material and preparation method thereof, take the raw material of following table 2 to prepare:

[0033] Table 2

[0034]

[0035] The above-mentioned modified coconut fiber is obtained through the following steps: take 20kg of coconut fiber and place it in a grinder to grind until the fiber length is less than or equal to 80 μm, and the aspect ratio is less than 10; after the grinding treatment, use an acrylic acid copolymer with a temperature of 50 ° C to grind After soaking the coconut fiber for 7 hours; then use low-carbon polyhydric alcohol with a temperature of 50°C to coat the soaked coconut fiber, and the bulk density of the coconut fiber is controlled at 1.5g / cm 3 Below, promptly make the required modified coconut fiber of raw material of the present invention;

[0036] The above-mentioned modified bamboo fiber is obtained through the following steps: adding water to 10kg of bamboo fiber to adj...

Embodiment 3

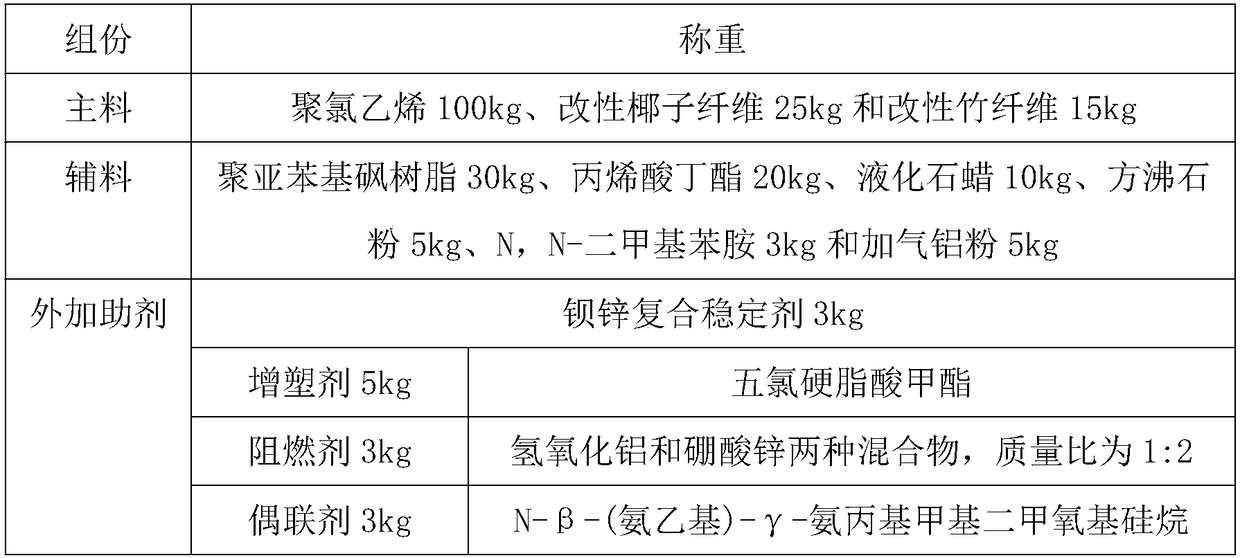

[0042] A high temperature-resistant PVC wood-plastic composite material is prepared by weighing the raw materials in the following table 3:

[0043] table 3

[0044]

[0045] The above-mentioned modified coconut fiber is obtained through the following steps: take 25kg of coconut fiber and place it in a grinder to grind until the fiber length is less than or equal to 100 μm, and the aspect ratio is less than 10; after the grinding treatment, use acrylic acid copolymer with a temperature of 55 ° C to The ground coconut fiber is soaked for 8 hours; then the soaked coconut fiber is coated with low-carbon polyhydric alcohol at a temperature of 55°C, and the bulk density of the coconut fiber is controlled at 2.0g / cm 3 Below, promptly make the required modified coconut fiber of raw material of the present invention;

[0046] Above-mentioned modified bamboo fiber is made through the following steps: 15kg bamboo fiber is added with water to adjust water content to 70%, sprays EM ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com