Surface modification nuclear power station control rod drive mechanism claw

A surface modification and driving mechanism technology, which is applied in the control of nuclear reactions, nuclear power generation, nuclear engineering, etc., can solve the problems of unfavorable batch production, low product qualification rate, and weak process controllability, so as to avoid secondary excitation Radiation dose, simple technical process, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

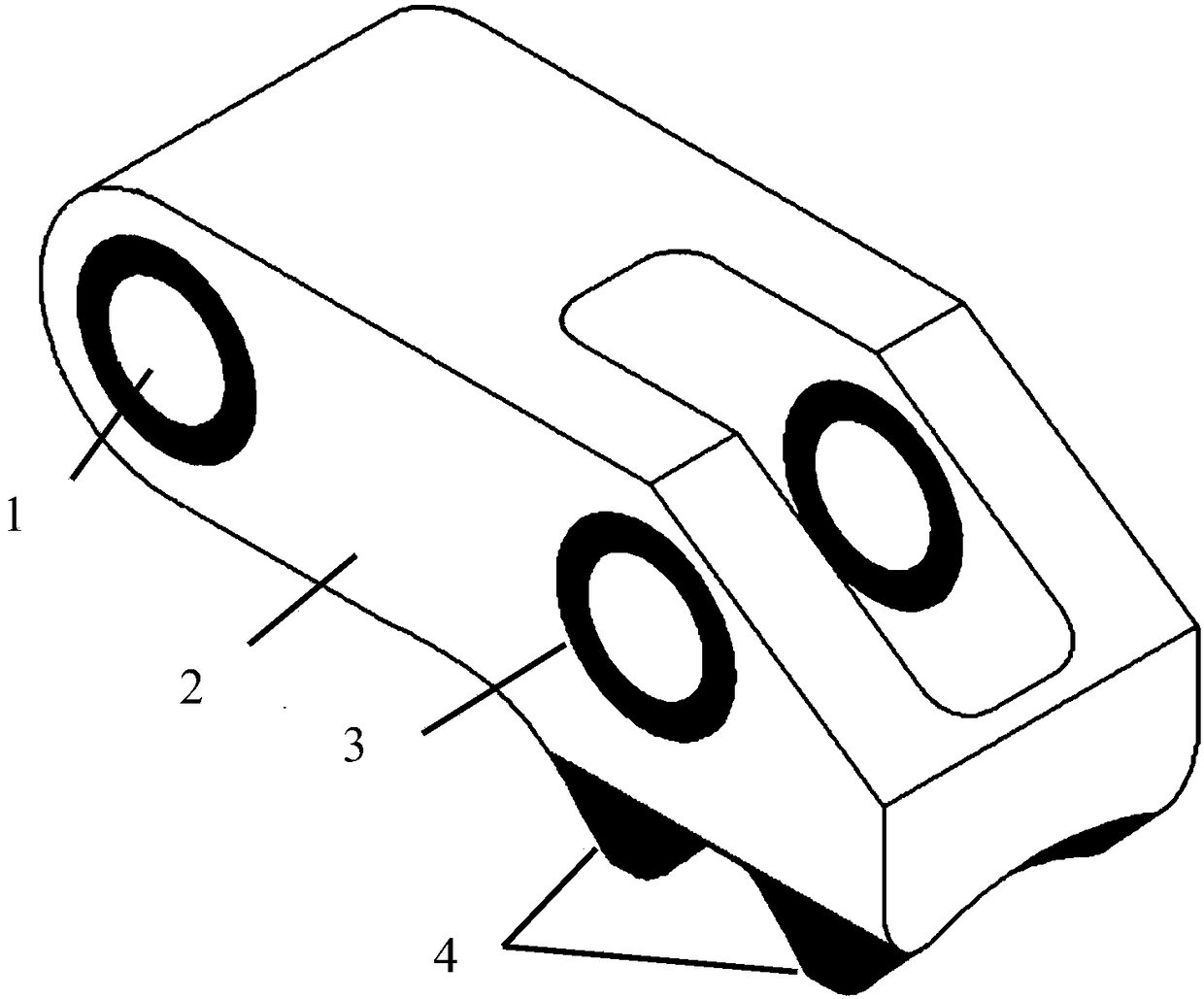

[0029] figure 1 It is a schematic diagram of the claws of the traditional surfacing control rod drive mechanism. Generally, 304LN stainless steel claw base 2 is used, and cobalt-based alloys are respectively surfacing on the first shaft hole, the second shaft hole, and the double hook teeth to form the first shaft hole surfacing layer 1, Shaft hole 2 surfacing layer 3, double hook tooth surfacing layer 4, to increase the wear resistance of these moving contact parts.

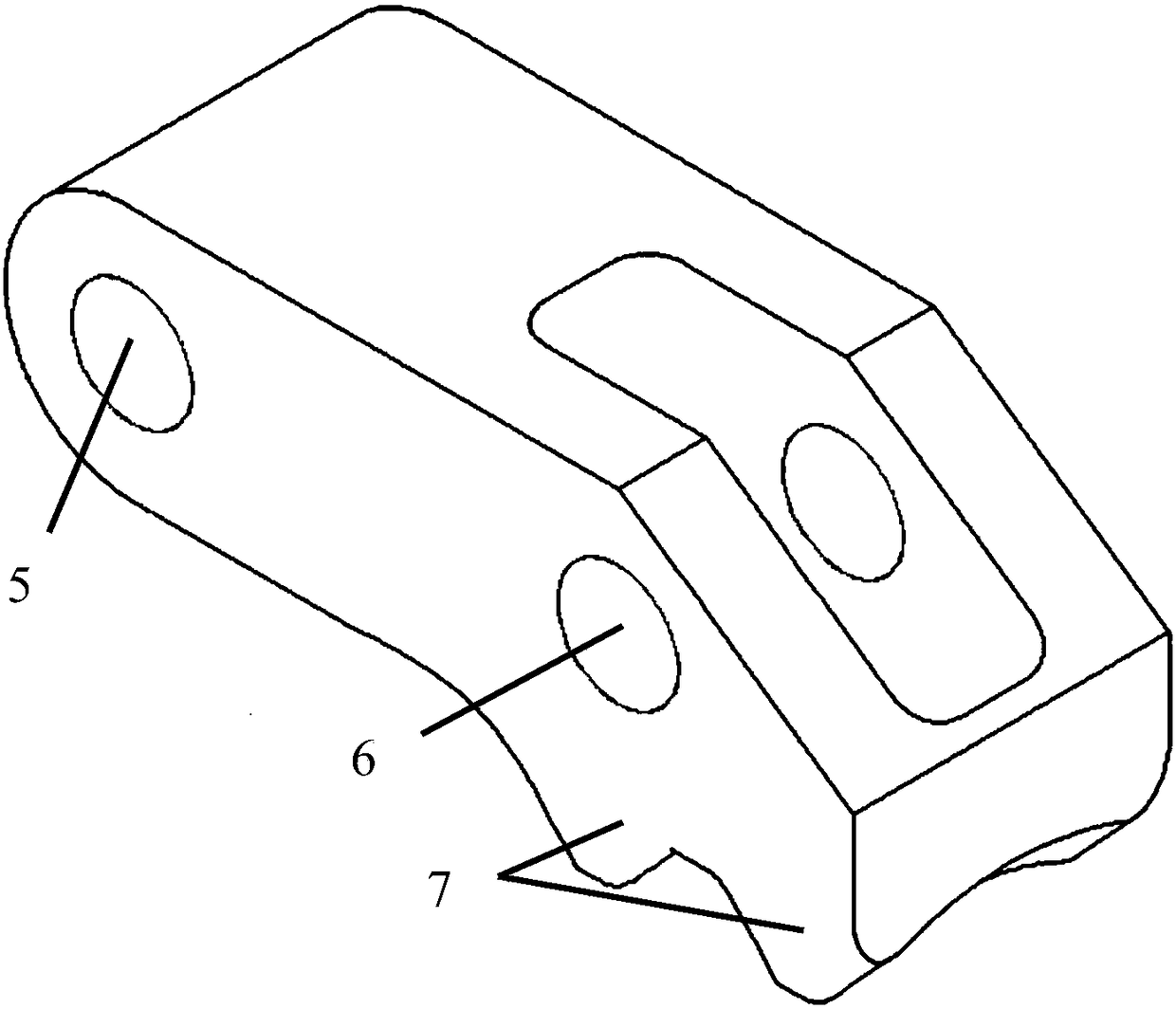

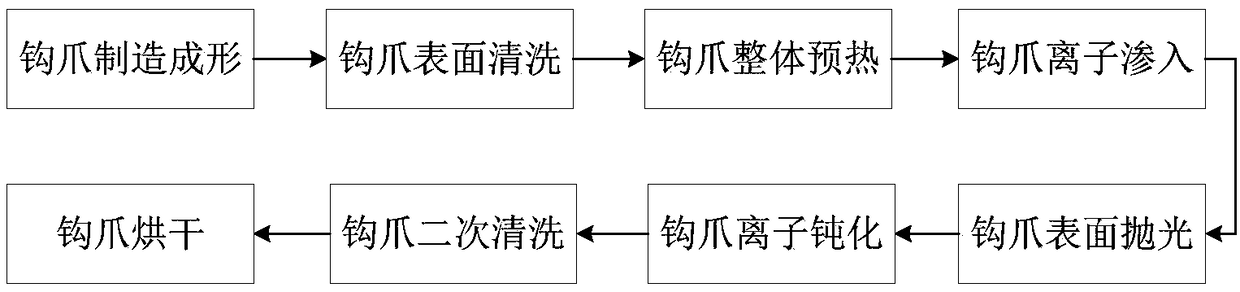

[0030] Such as figure 2 and 3 As shown, the claw of the surface-modified nuclear power plant control rod drive mechanism provided by the present invention is first manufactured and shaped, and has an integrated structure, including typical features such as the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com