Surface-modified nuclear power plant voltage stabilizer sprayer rotary water core

A surface modification, nuclear power plant technology, applied in spraying devices with movable outlets, spraying devices, metal material coating processes, etc., can solve problems such as complex structure, achieve simple technical process, simple surface modification technology and improved Effects on longevity and operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

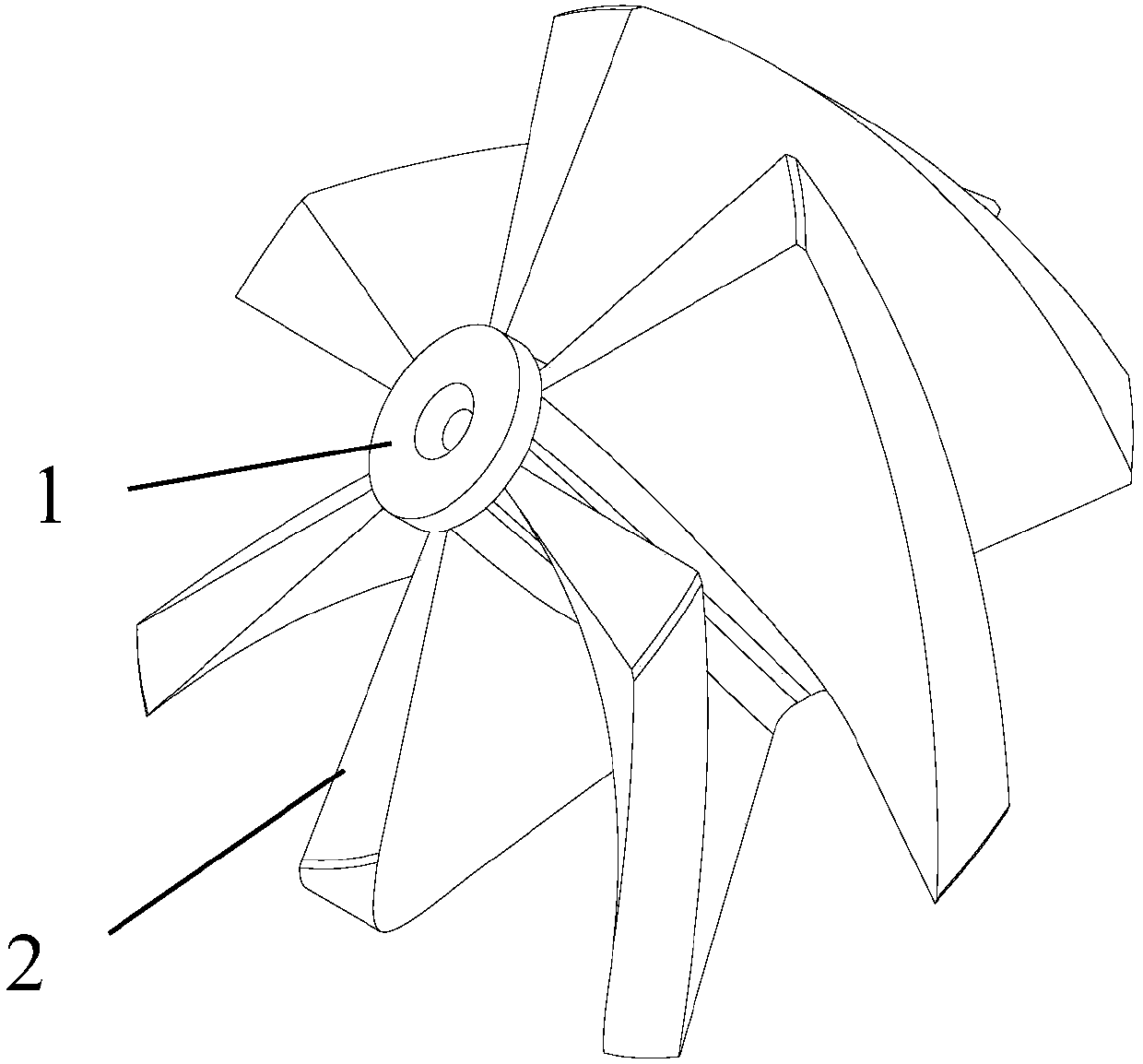

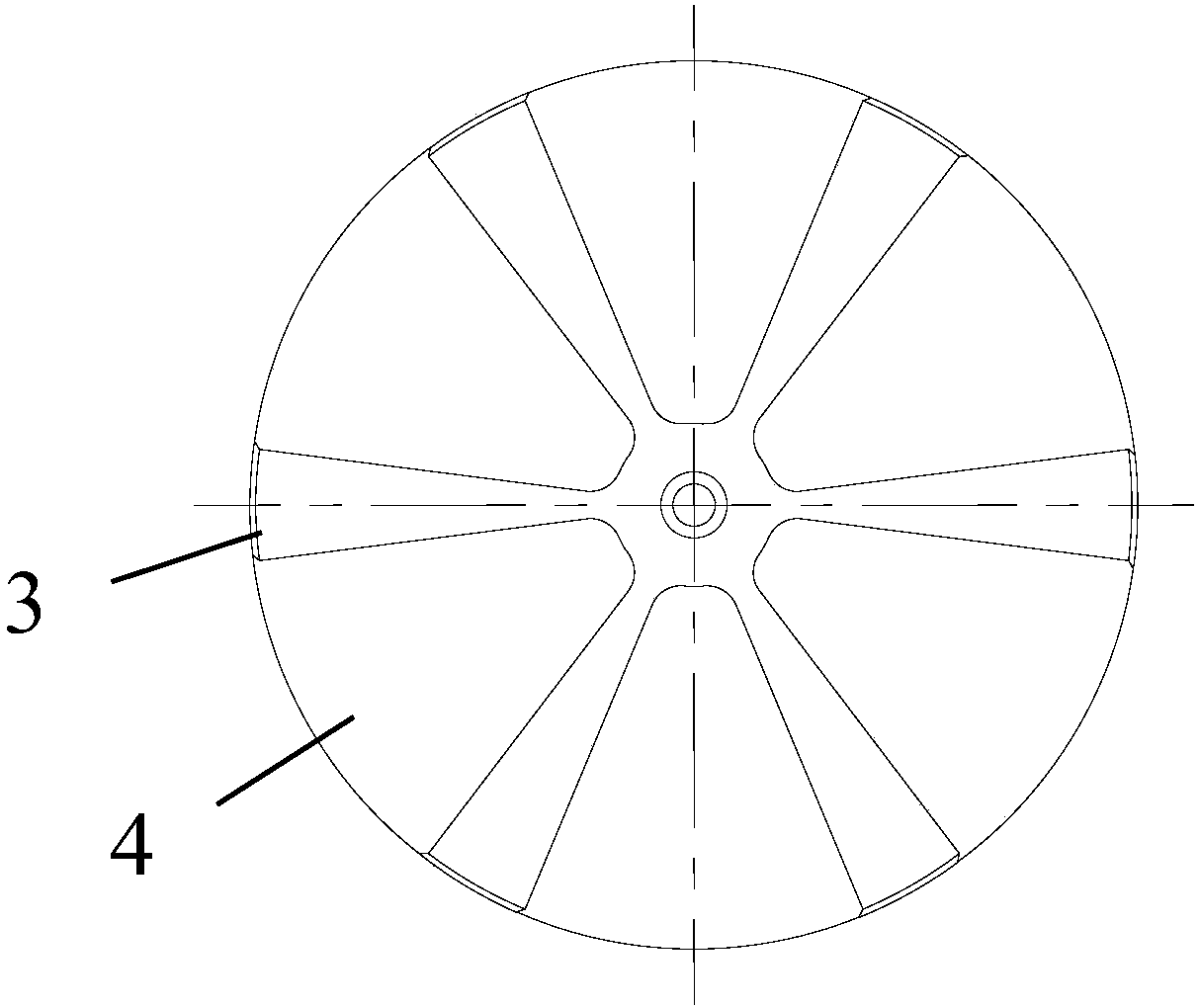

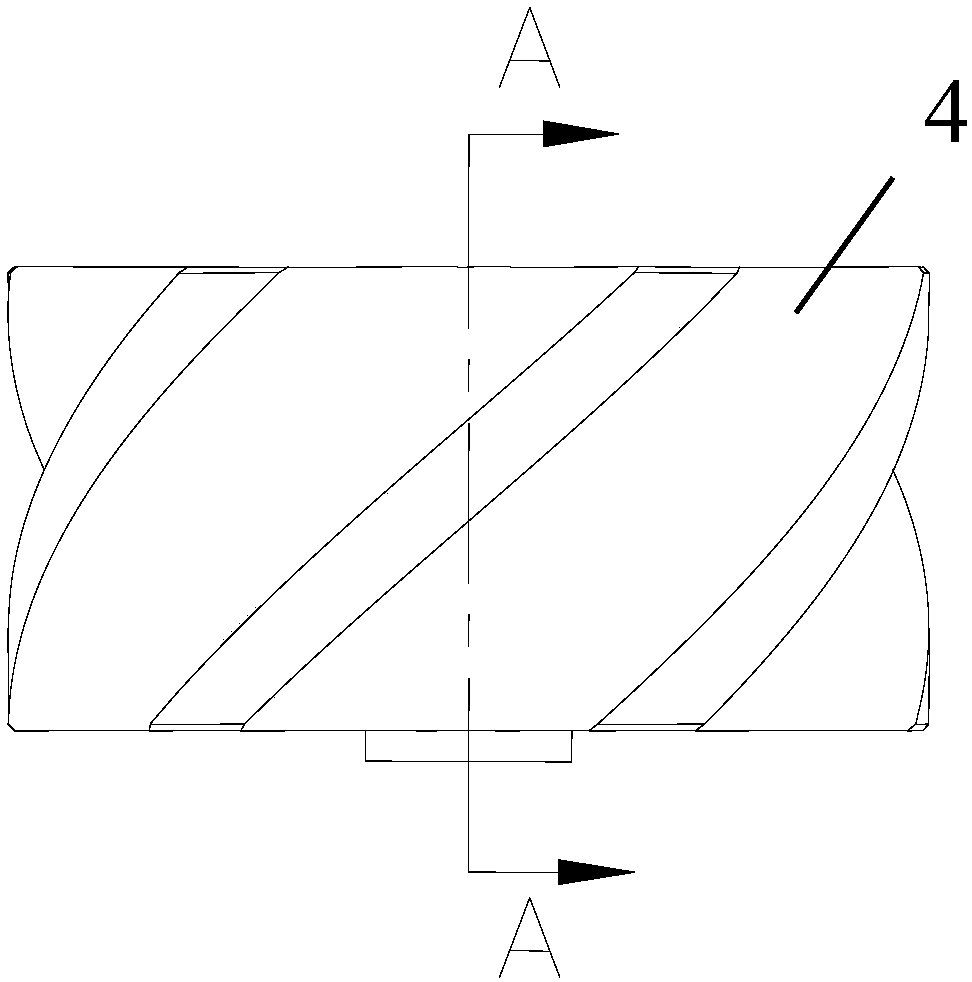

[0031] Such as Figure 1-3 As shown, the surface-modified nuclear power plant pressurizer sprayer water spin core provided by the present invention includes two parts: a water spin core main body 1 and a water spin splitter plate 2 . The main body 1 of the water vortex core is cylindrical, and the water vortex distributor plate 2 has 6 evenly distributed spiral blades, which are distributed along the circumferential direction of the main body 1 of the water vortex core. Adjacent blades form a spiral groove flow channel 4 with large flow channel area, small flow resistance and strong pressure adaptability.

[0032] Such as Figure 4 As shown, the water swirl core also has a supplementary flow channel 6, and the lower end of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com