Boron extracting method

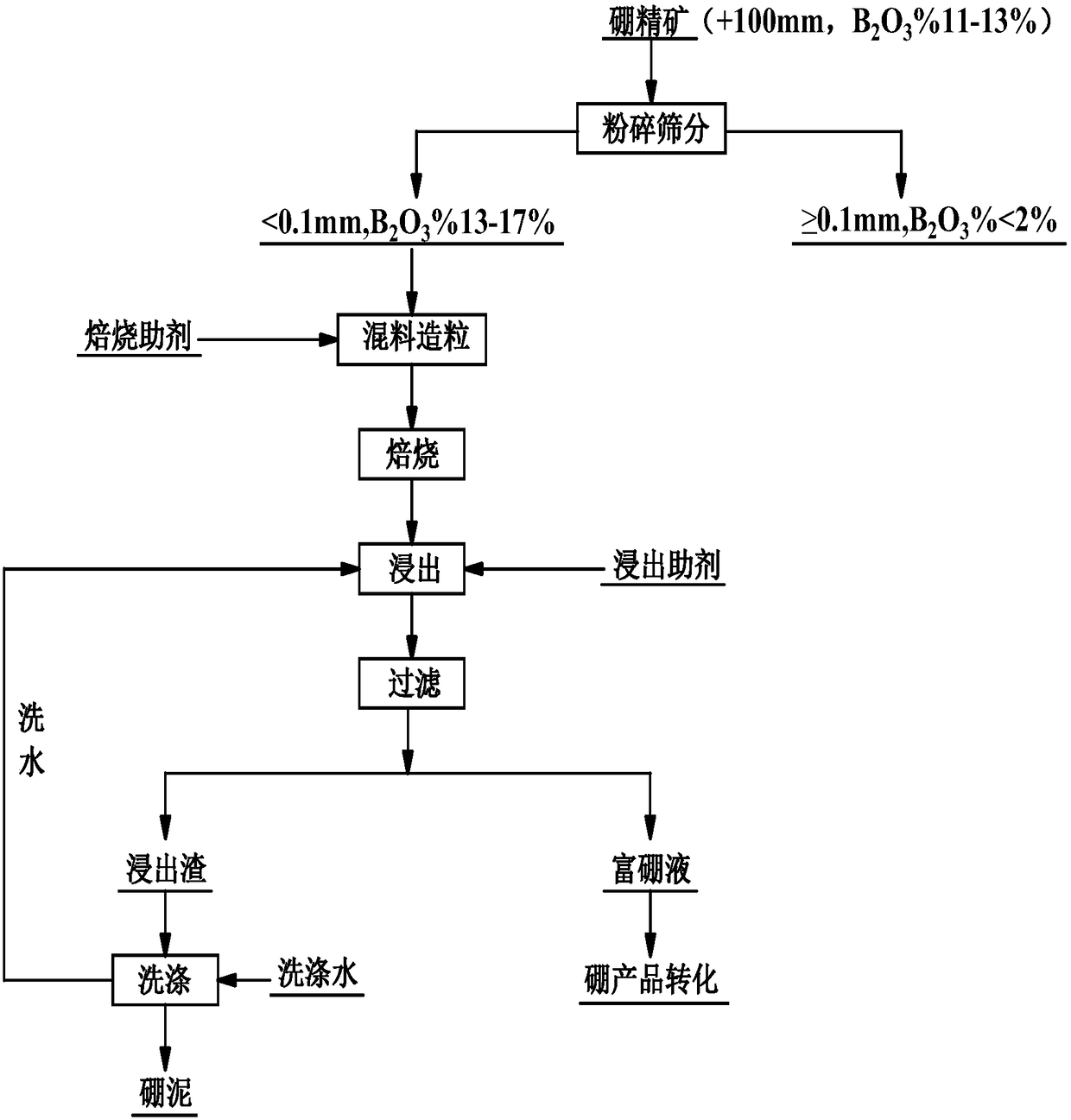

A boron ore and boron-rich technology, applied in chemical instruments and methods, borates, boron compounds, etc., can solve the problems of incomplete roasting of ore powder, slow filtration speed, high sodium roasting temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A method for extracting boron from boron concentrate, said method comprising the steps of:

[0070] This embodiment uses boron concentrate containing B 2 o 3 9%, MgO 25%, SiO 2 20%, Fe 10%.

[0071] (1) Carry out ball milling with 100g of boron concentrate, the part of ball milling ore powder particle size≤75 μ m accounts for 51% of the total mass of all boron concentrate ore, and screen out the ore powder with particle size greater than 0.1mm;

[0072] (2) Adding soda lime that accounts for 5% of the mass fraction of the mineral powder in the mineral powder, after ball milling and mixing for 0.5h, the mineral powder is pressed into block;

[0073] (3) Putting the prepared sample into a roasting furnace and roasting in an air atmosphere, the roasting temperature is 650° C., and after roasting for 4 hours, boiled boron ore is obtained, and the reaction activity is 91%;

[0074] (4) Add water and 5% sodium carbonate and 0.5% activated carbon to the boiled boron ore,...

Embodiment 2

[0077] A method for extracting boron from boron concentrate, said method comprising the steps of:

[0078] This embodiment uses boron concentrate containing B 2 o 3 20%, MgO 37%, SiO 2 35%, Fe 18%.

[0079] (1) Carry out ball milling with 100g of boron concentrate, the part of the ball milled ore powder particle size≤75 μm accounts for 90% of the total mass of all boron concentrates, and screen out the ore powder with a particle size greater than 0.1mm;

[0080] (2) Add quicklime and 2% coke powder that account for 25% of the mass fraction of the mineral powder in the mineral powder, and after ball milling and mixing for 3 hours, the mineral powder is pressed into block;

[0081] (3) Putting the prepared sample into a roasting furnace and roasting under an oxygen atmosphere, the roasting temperature is 900°C, and after roasting for 0.5h, boron ore is obtained, and the reaction activity is 93%;

[0082](4) Add water and 35% sodium bicarbonate and 5% activated carbon to the...

Embodiment 3

[0085] A method for extracting boron from boron concentrate, said method comprising the steps of:

[0086] This embodiment uses boron concentrate containing B 2 o 3 13%, MgO 30%, SiO 2 25%, Fe 16%.

[0087] (1) Carry out ball milling with 100g of boron concentrate, the part of ball milled ore powder particle size≤75 μ m accounts for 86% of the total mass of all boron concentrate ore, and screen out the ore powder with particle size greater than 0.1mm;

[0088] (2) Add limestone that accounts for 15% of the mass fraction of ore powder and coke powder that accounts for 1% of the mass fraction of ore powder to the ore powder, and after ball milling and mixing for 1 hour, the ore powder is pressed into block;

[0089] (3) Putting the prepared sample into a roasting furnace and roasting in an air atmosphere, the roasting temperature is 700°C, after roasting for 1.5 hours, boron ore is obtained, and the reaction activity is 92%;

[0090] (4) Add water, sodium carbonate account...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com