A kind of hollow foam material and its preparation method and application

A foam material and hollow technology, applied in the field of foam materials, can solve the problems of low fluid mass transfer efficiency, poor mechanical properties, poor corrosion resistance, etc., and achieve high mass transfer efficiency and mechanical properties, improved structural stability, and simple technical process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

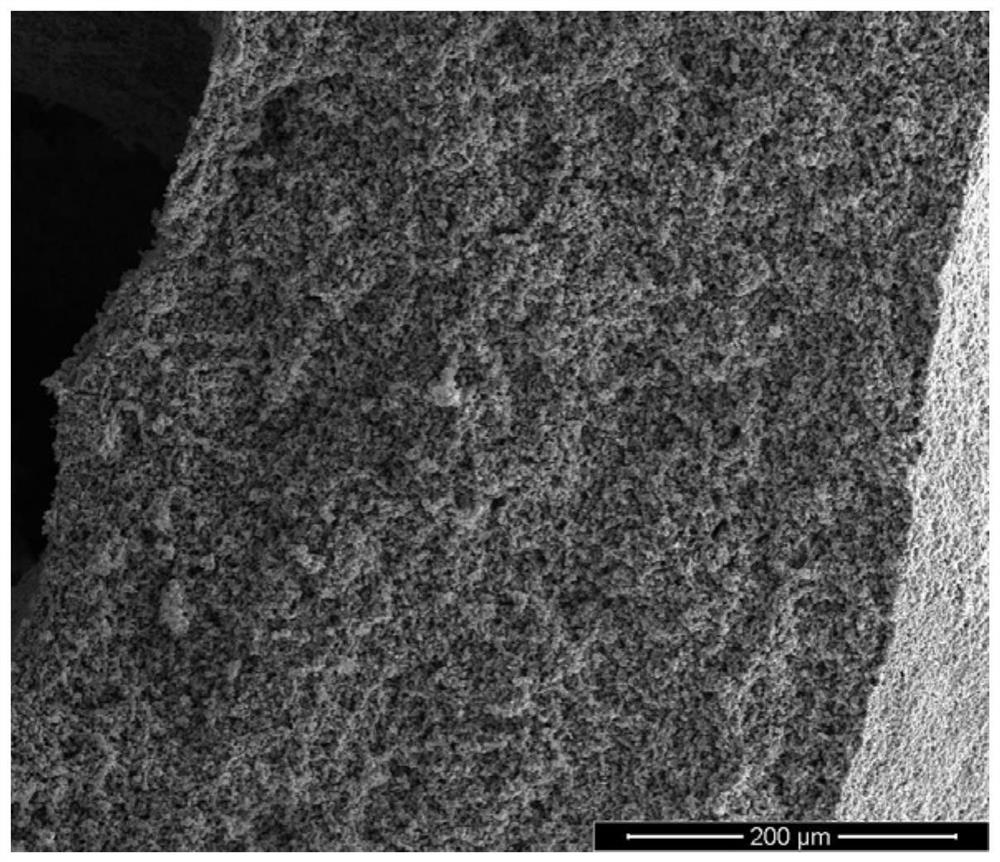

[0061] The preparation process of this embodiment is the preparation process of the hollow foam silicon carbide material with the microchannel wall of the porous structure:

[0062] (1) Preparation of thickening slurry: mix polyvinyl alcohol powder, epoxy resin, curing agent, and ethanol through ball milling to make thickening slurry, and mix polyvinyl alcohol, epoxy resin, curing agent, and ethanol The ratio is 50-500g: more than 0-500g: 10-100g: 1000mL (that is, for every 1000mL solvent in the slurry, there are 50-500g polyvinyl alcohol powder, more than 0-500g epoxy resin and 10-100g epoxy resin corresponding curing agent).

[0063] (2) Preparation of microchannel tube wall green body layer slurry: silicon carbide powder (average particle size 5 μm), silicon powder (average particle size 3.5 μm), phenolic resin, p-toluenesulfonic acid (curing agent), ethanol According to the ratio of 50-500g: 50-500g: 50-200g: (greater than 0 to 0.2) times the mass of phenolic resin: 1000m...

Embodiment 2

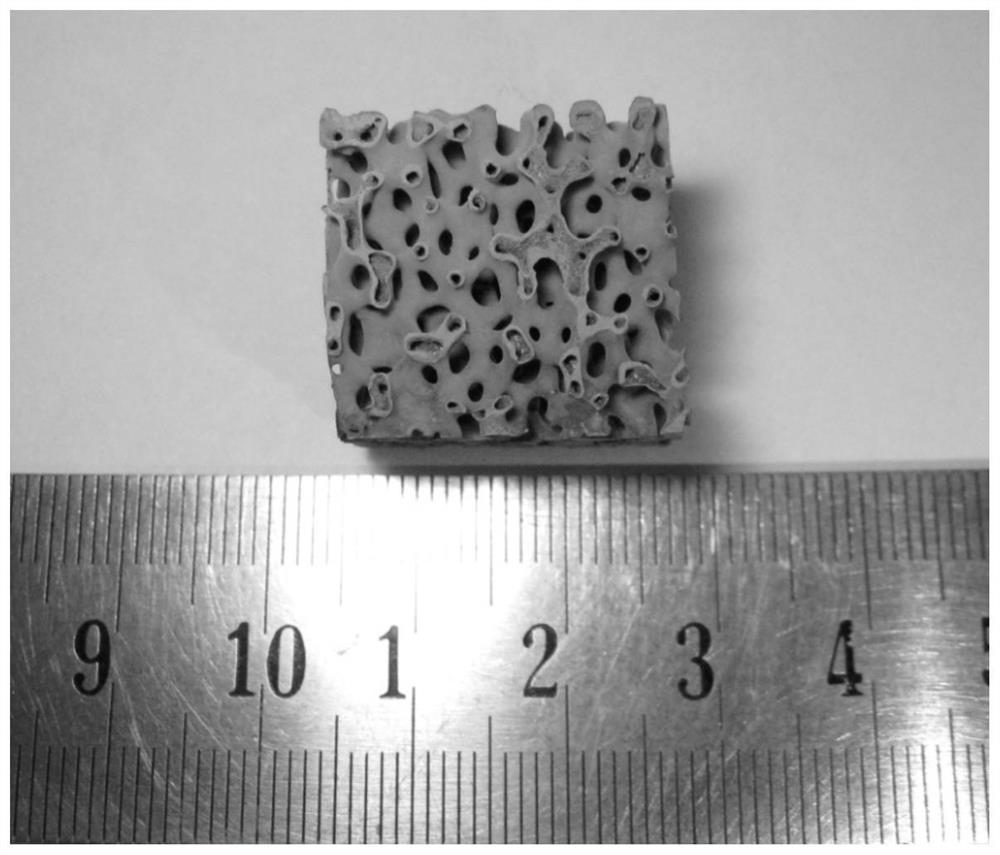

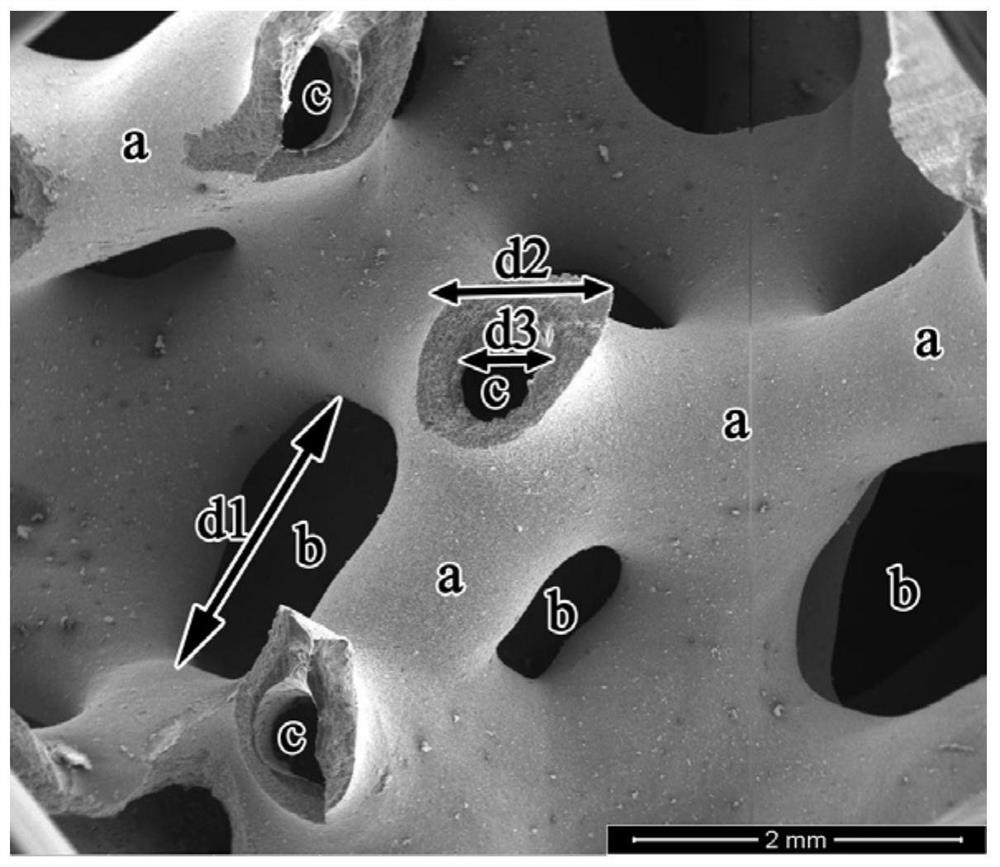

[0070]The preparation process of this embodiment is the preparation process of a hollow silicon carbide foam material with a microchannel wall of a dense structure: the difference between this embodiment and Example 1 is that the molding process described in step (6) is: the molding precursor The body is placed in a vacuum sintering furnace, and silicon powder particles with an average particle size of 3mm are evenly placed on the shaped precursor sample. Under vacuum conditions, the temperature is 900-2500°C, and the holding time is 10min-6h. In the obtained hollow foam material, the average size of the macroscopic three-dimensional interconnected openings is 0.5 mm. The supporting framework itself is a three-dimensionally connected microchannel with a hollow structure, the average size of the inner diameter of the hollow microchannel is 250 μm, and the average size of the outer diameter is 550 μm. The wall of the microchannel is a dense structure, and its chemical compositi...

Embodiment 3

[0072] The preparation process of this example is the preparation process of a hollow foamed alumina material with a microchannel wall of a porous structure: the difference between this example and Example 1 is that the epoxy resin in step (1) is replaced by polyurethane. In step (2), the slurry of the microchannel tube wall green body layer is composed of: alumina powder (average particle size 5 μm), phenolic resin, p-toluenesulfonic acid (curing agent), and ethanol in proportions of 50 to 500 g: 50 to 200g: (greater than 0 to 0.2) times the mass of phenolic resin: 1000mL. The polyurethane resin foam whose average pore diameter is 3 mm in step (3) is replaced with the polyurethane resin foam material whose average mesh size is 5 mm. In step (3), the thickness of the skeleton ribs supporting the skeleton reaches a pre-designed value of 600 μm. In the obtained hollow foam material, the average size of the macroscopic three-dimensional interconnected openings is 4mm. The suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com