Method for combined extraction of alpinia officinarum hance volatile oil and galangin from alpinia officinarum hance

A technology of galangin and combined extraction is applied in the directions of fat oil/fat production, bulk chemical production, fat production, etc., and can solve problems such as inability to efficiently extract and utilize, residual galangin not being effectively extracted and utilized, waste of raw materials, and the like, Achieve the effect of enhancing the usable value, scientific and reasonable and efficient technical approach, and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

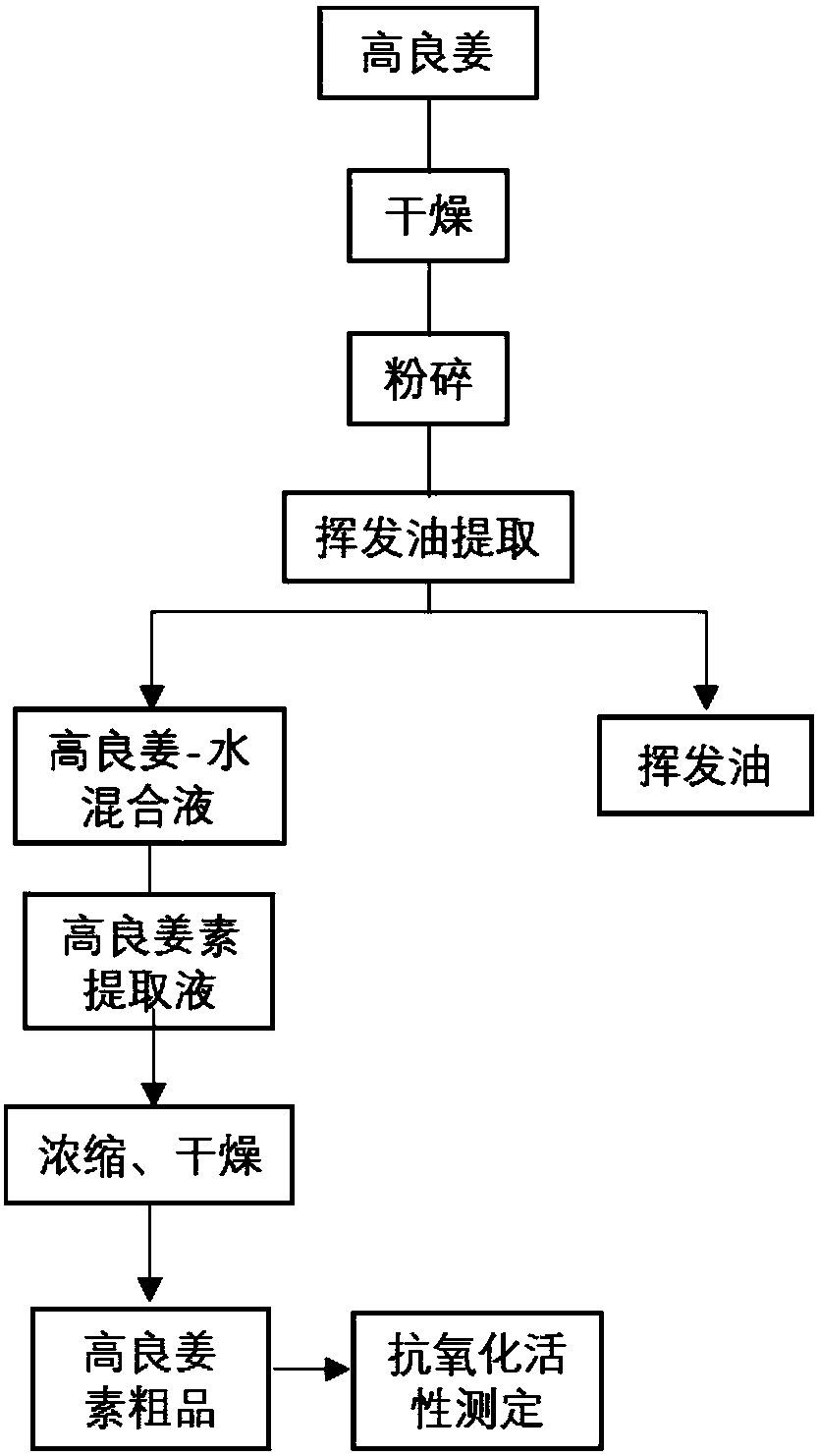

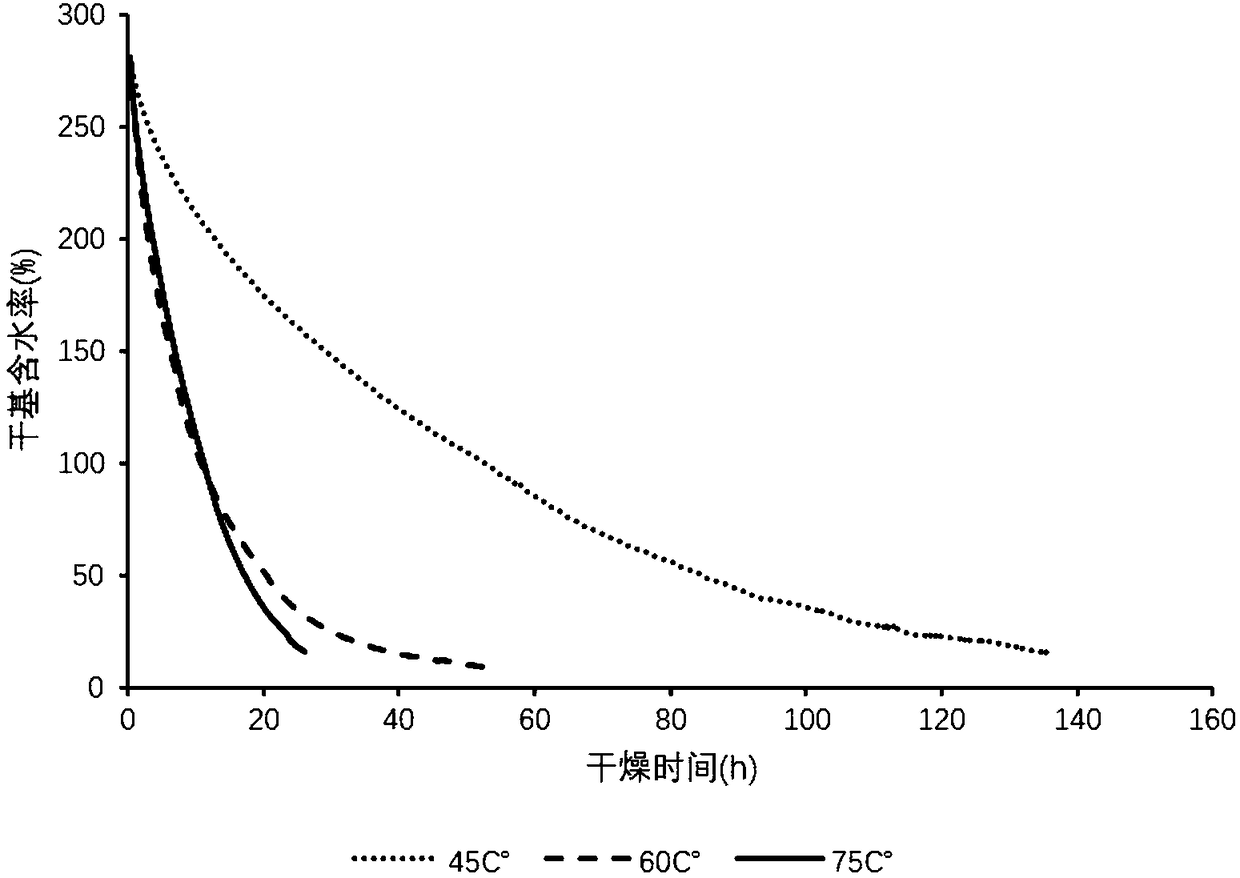

[0044] S1. Drying: fresh galangal is used as raw material, after being selected and cleaned, cut into pieces, remove the remaining stems and leaves, and then put them into heat pumps that have been preheated to 60°C for drying until the water content is 11% or less.

[0045] S2. Crush: Take the galangal obtained in S1, cut it into small pieces and remove the remaining stems and leaves, then immediately crush and sieve the galangal with a mesh number of 40 to obtain galangal powder.

[0046] S3. Extraction of volatile oil: take a certain amount of S2 gained galangal powder in supercritical CO 2 In the reaction kettle, the extraction pressure is 20MPa, the extraction temperature is 40°C, and the extraction time is 1.5h. The volatile oil is collected to obtain the light yellow transparent galanga volatile oil and the residue.

[0047] S4. Extraction of galangin: in the residue obtained in step S3, add an ethanol solution with a volume percentage concentration of 57%, a solid-liq...

Embodiment 2

[0051] This embodiment provides a method for jointly extracting galangal volatile oil and galangin. Others are the same as in embodiment 1, except that the drying described in step S1 is dried with hot air at a drying temperature of 75°C until the water content is 11. % or less.

[0052] In this example, the yield of volatile oil was 2.13mL / 100g, and the content of galangin was 9.58g / 100g.

Embodiment 3

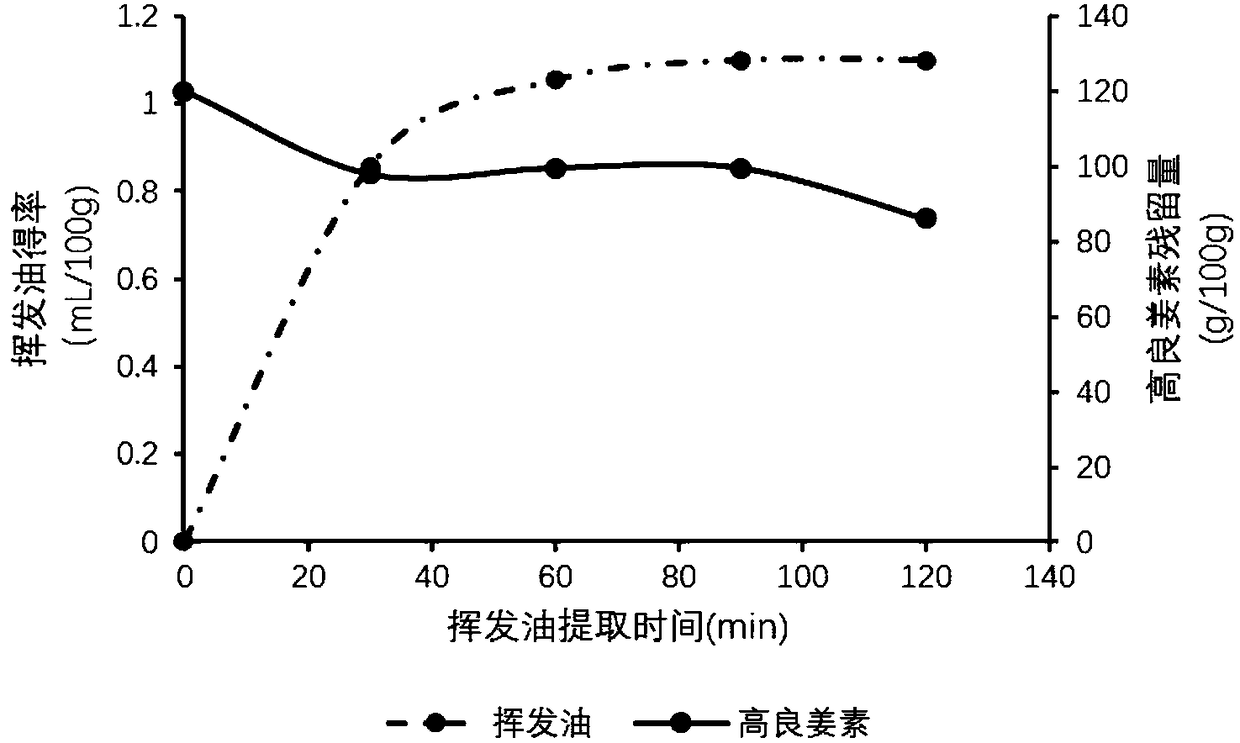

[0054] This embodiment provides a method for jointly extracting galangal volatile oil and galangin. Others are the same as in Example 1, except that the extraction of the volatile oil described in step S3 adopts steam distillation, and the soaking time is 0 to 10 h. The liquid ratio is calculated in g / mL, which is 1:5~1:20, and the extraction time is 30~240min. Preferably, the soaking time is 0.5h, the solid-liquid ratio is 1:10, and the extraction time is 70min.

[0055] The present embodiment volatile oil impurity is less, operation requirement and technical difficulty requirement are relatively low, can guarantee the yield of higher volatile oil and galangin, in the present embodiment, volatile oil yield is 1.14mL / 100g, and galangin content is 9.69g / 100g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com