Polyurethane foam dressing and preparation method thereof

A technology of polyurethane foam and water-based polyurethane, applied in the field of medicine, can solve problems such as secondary trauma, wound dressing adhesion, easy breeding of bacteria, etc., and achieve the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

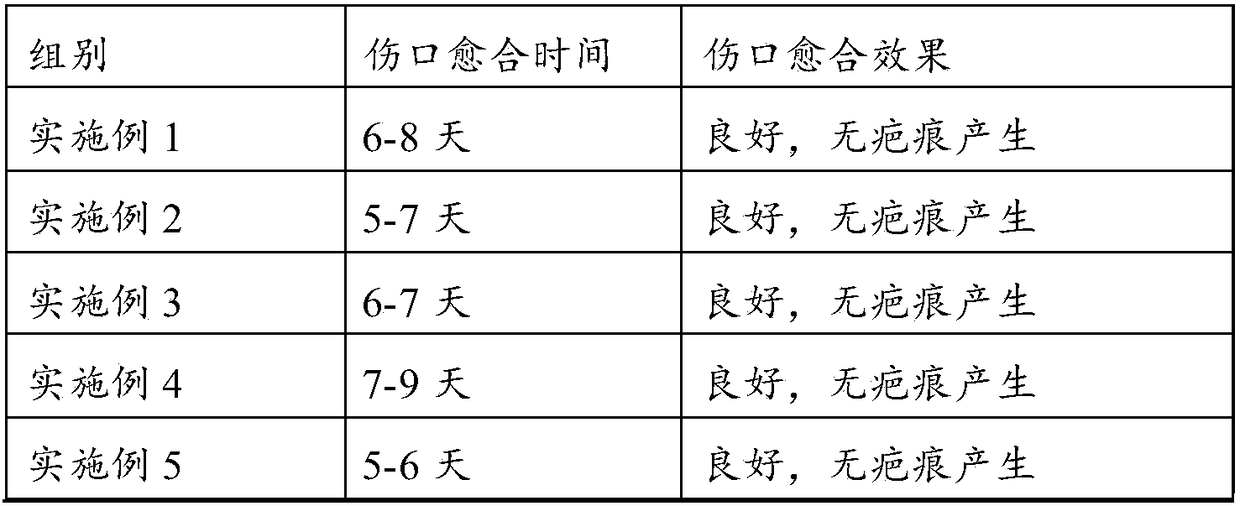

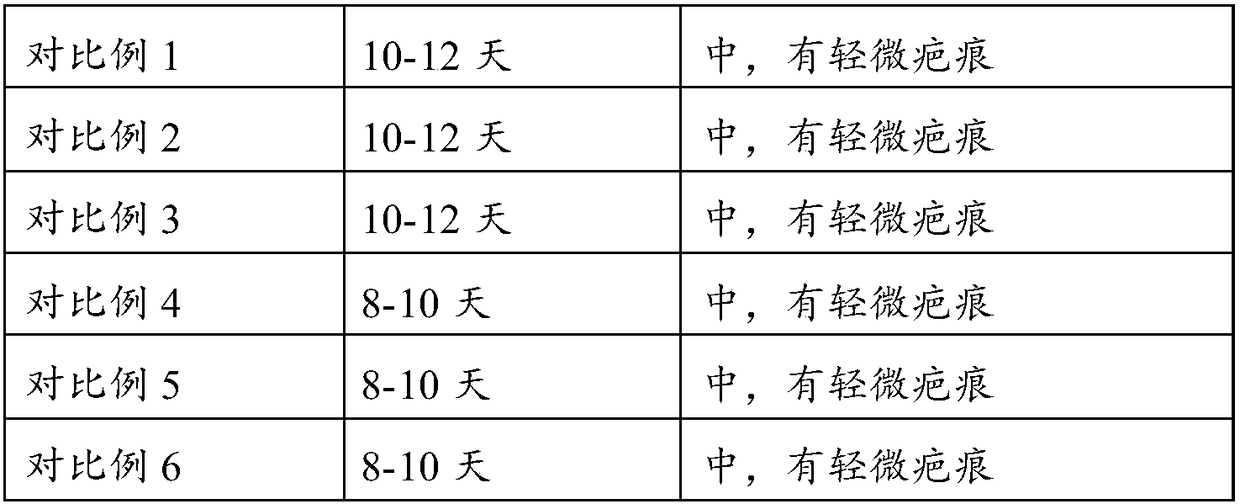

Examples

Embodiment 1

[0042] The preparation of embodiment 1 polyurethane foam dressing of the present invention

[0043] raw material:

[0044] 80 parts of Bayhydur 2547, 12 parts of carboxymethyl chitosan, 0.2 parts of tetrandrine, 0.1 part of tamoxifen, 60 parts of diphenylmethane diisocyanate (MDI), 2 parts of sodium lauryl sulfate, 1 part of stannous octoate , 2 parts of tetrahydrofuran, and 100 parts of purified water. Wherein the degree of substitution of carboxymethyl chitosan is 85%, and the degree of deacetylation is 90%.

[0045] Preparation:

[0046] ①Weigh Bayhydur 2547, tetrahydrofuran, carboxymethyl chitosan, tetrandrine, tamoxifen, sodium lauryl sulfate, stannous octoate, purified water respectively in the proportioning by weight, at room temperature, 2500r / min After stirring for 4 minutes under the same conditions.

[0047] ② Weigh and add the diphenylmethane diisocyanate (MDI) in the proportion by weight, continue stirring for 1 minute, put it into a foaming mold and keep it w...

Embodiment 2

[0048] Embodiment 2 The preparation of polyurethane foam dressing of the present invention

[0049] raw material:

[0050] 90 parts of Bayhydur2655, 15 parts of hydroxypropyl chitosan, 0.1 part of tetrandrine, 0.2 part of tamoxifen, 120 parts of diphenylmethane diisocyanate (MDI), 3 parts of silicone oil, 2 parts of stannous octoate, 3 parts of petroleum ether , 120 parts of purified water. Among them, the degree of substitution of hydroxypropyl chitosan is 80%, and the degree of deacetylation is 85%.

[0051] Preparation:

[0052] ① Weigh Bayhydur 2655, petroleum ether, hydroxypropyl chitosan, tetrandrine, tamoxifen, organic silicone oil, stannous octoate, purified water and stir at room temperature for 5 minutes under the condition of 2000r / min rear.

[0053] ②Weigh and add the diphenylmethane diisocyanate (MDI) in the proportion by weight, continue to stir for 1min, put it into a foaming mold and keep it warm at 60°C for 40 minutes, and cut it to obtain a polyurethane f...

Embodiment 3

[0054] Embodiment 3 The preparation of polyurethane foam dressing of the present invention

[0055] raw material:

[0056] 85 parts of Bayhydur 3100, 14 parts of chitosan quaternary ammonium salt, 0.6 part of tetrandrine, 0.6 part of tamoxifen, 70 parts of diphenylmethane diisocyanate (MDI), 2 parts of polysorbate (Tween), 2 parts of stannous octoate parts, 2 parts of tetrahydrofuran, and 100 parts of purified water. Wherein the degree of deacetylation of chitosan quaternary ammonium salt is 95%.

[0057] Preparation:

[0058] 1. Take Bayhydur 3100, tetrahydrofuran, chitosan quaternary ammonium salt, tetrandrine, tamoxifen, polysorbate (Tween), stannous octoate, purified water respectively in the proportioning by weight, at room temperature, 2000r / min After stirring for 5 min under the conditions.

[0059] ②Weigh and add the diphenylmethane diisocyanate (MDI) in the proportion by weight, continue to stir for 1min, put it into a foaming mold and keep it warm at 60°C for 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com