Preparation method of high-strength porous piezoelectric ceramic

An electro-ceramic, high-strength technology, applied in the field of preparation of high-strength porous piezoelectric ceramics, can solve the problems of not meeting market requirements, poor piezoelectric performance, low porosity, etc., to avoid breakdown, high porosity, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

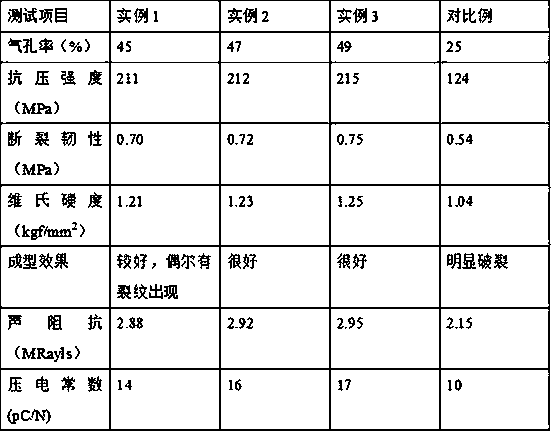

Examples

example 1

[0024]Mix and stir acrylamide, N,N-methylenebisacrylamide and tert-butanol for 10 minutes at a mass ratio of 2:1:3 to obtain a mixture, mix the mixture with deionized water at a mass ratio of 1:3 and place In the beaker, continue to stir for 11 minutes to obtain a self-made mixture; weigh 10g of citrus and 16g of spinach and mix them in a blender for 16 minutes to obtain a crushed product. Mix the crushed product with distilled water at a mass ratio of 1:5 and put Put the beaker into a beaker, place the beaker in an ultrasonic oscillator, conduct ultrasonic extraction for 45 minutes at a temperature of 60°C and a power of 180W, filter after extraction, collect the filtrate, and distill the filtrate under reduced pressure to obtain a self-made plant extract. Finally, mix the self-made plant extract with the above-mentioned self-made mixed solution at a volume ratio of 1:1, and ultrasonically treat it with a power of 200W for 10 minutes, let it stand for layers, separate and remo...

example 2

[0026] Mix and stir acrylamide, N,N-methylenebisacrylamide and tert-butanol for 11 minutes at a mass ratio of 2:1:3 to obtain a mixture, mix the mixture with deionized water at a mass ratio of 1:3 and place In the beaker, continue to stir for 13 minutes to obtain a self-made mixture; weigh 11g of citrus and 18g of spinach and mix them in a blender for 18 minutes to obtain a crushed product. Mix the crushed product with distilled water at a mass ratio of 1:5 and put put into a beaker, place the beaker in an ultrasonic oscillator, conduct ultrasonic extraction for 55 minutes at a temperature of 70°C and a power of 190W, filter after extraction, collect the filtrate, and distill the filtrate under reduced pressure to obtain a self-made plant extract. Finally, mix the self-made plant extract with the above-mentioned self-made mixed solution at a volume ratio of 1:1, and ultrasonically treat it with a power of 230W for 11 minutes, let it stand for layers, separate and remove the low...

example 3

[0028] Mix acrylamide, N,N-methylenebisacrylamide and tert-butanol with a mass ratio of 2:1:3 and stir for 12 minutes to obtain a mixture, mix the mixture with deionized water at a mass ratio of 1:3 and place In the beaker, continue to stir for 15 minutes to obtain a self-made mixture; weigh 12g of citrus and 20g of spinach and mix them in a blender for 20 minutes to obtain a crushed product. Mix the crushed product with distilled water at a mass ratio of 1:5 and put Put it into a beaker, place the beaker in an ultrasonic oscillator, conduct ultrasonic extraction for 60 minutes at a temperature of 80°C and a power of 200W, filter after extraction, collect the filtrate, and distill the filtrate under reduced pressure to obtain a self-made plant extract. Finally, mix the self-made plant extract with the above-mentioned self-made mixed solution at a volume ratio of 1:1, and ultrasonically treat it with a power of 260W for 12 minutes, let it stand for layers, separate and remove th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com