A kind of preparation method of liquid polycarboxylate water reducer

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixtures, can solve the problems of inability to react and synthesize, and achieve the effects of controllable reaction rate, simplified synthesis process, and avoiding detonation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

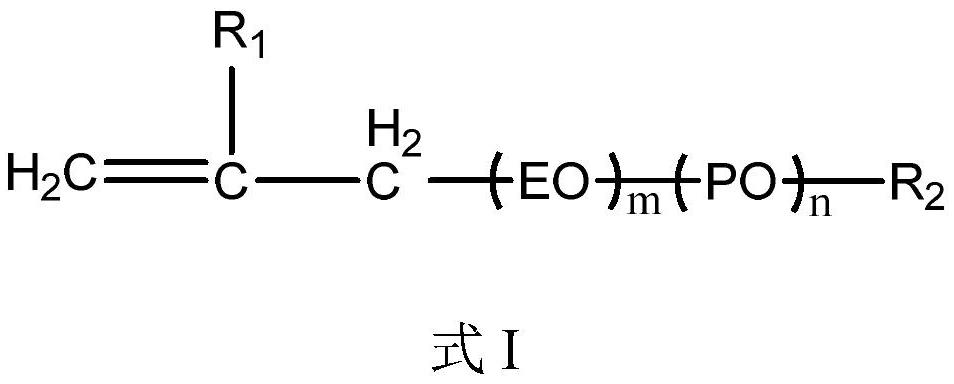

Method used

Image

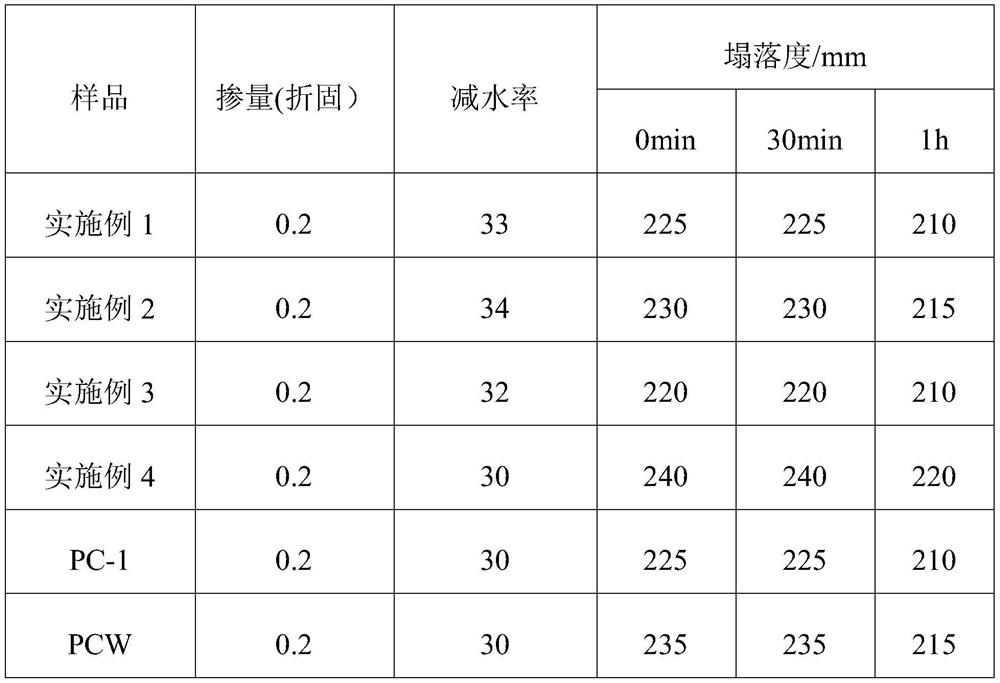

Examples

Embodiment 1

[0036] This embodiment provides a synthetic method of polycarboxylate water reducer, which specifically includes the following steps:

[0037] 1. Preparation of isopentenyl polyoxyethylene polyoxypropylene ether

[0038] (1) Add 60 g of prenol and 0.25 g of NaOH to the reaction kettle, and replace the air in the kettle with nitrogen.

[0039] (2) When the temperature of the kettle rises to 110°C, start to feed 1116g of ethylene oxide and 840g of propylene oxide, keep the polymerization reaction temperature at 130°C, and the reaction pressure at 0.35Mpa. The reaction product of polyoxyethylene polyoxypropylene ether.

[0040] (3) neutralize the above-mentioned reaction product, then degas in the reactor to obtain m=30, n=20, isopentenyl polyoxyethylene polyoxypropylene ether with an average molecular weight of 2553.16.

[0041] 2. Preparation of polycarboxylate water reducer

[0042] (1) Put 270 g of isopentenyl polyoxyethylene polyoxypropylene ether (m=30, n=20, average molec...

Embodiment 2

[0046] This embodiment provides a synthetic method of polycarboxylate water reducer, which specifically includes the following steps:

[0047] 1. Preparation of isobutylene-based polyoxyethylene polyoxypropylene ether

[0048] (1) Add 85 g of isopentenol and 0.35 g of KOH as an alkali catalyst into the reaction kettle, and replace the air in the kettle with nitrogen.

[0049] (2) When the temperature of the kettle rises to 100-110°C, start to feed 2440g of ethylene oxide and 800g of propylene oxide, keep the polymerization reaction temperature at 100-110°C, and the reaction pressure at 0.35Mpa. After aging for 3 hours, the obtained Reaction product of isopentenyl polyoxyethylene polyoxypropylene ether.

[0050] (3) neutralize the above-mentioned reaction product, then degas in the reactor to obtain m=51, n=15, isopentenyl polyoxyethylene polyoxypropylene ether with an average molecular weight of 3173.85.

[0051] 2. Preparation of polycarboxylate water reducer

[0052] (1) ...

Embodiment 3

[0056] This embodiment provides a synthetic method of polycarboxylate water reducer, which specifically includes the following steps:

[0057] 1. Preparation of isobutylene-based polyoxyethylene polyoxypropylene ether

[0058] (1) Add 86 g of isobutenol and 0.25 g of alkali catalyst NaOH into the reaction kettle, and replace the air in the kettle with nitrogen.

[0059] (2) When the temperature of the kettle rises to 100°C, 1720g of ethylene oxide and 830g of propylene oxide are introduced into the reactor, the polymerization temperature is kept at 100°C, and the reaction pressure is 0.25Mpa. The reaction product of oxyethylene polyoxypropylene ether.

[0060] (3) neutralize the above-mentioned reaction product, then degas in the reactor to obtain m=60, n=1, isobutylene-based polyoxyethylene polyoxypropylene ether with an average molecular weight of 2757.2.

[0061] 2. Preparation of polycarboxylate water reducer

[0062] (1) In the four-necked flask, add 280 g of isobutyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com