Rubber capable of expanding after contact of water, and preparation method thereof

A water-swelling and rubber technology, applied in the field of rubber preparation, can solve the problem of less research on expanded rubber, and achieve the effect of good stability and strong water retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

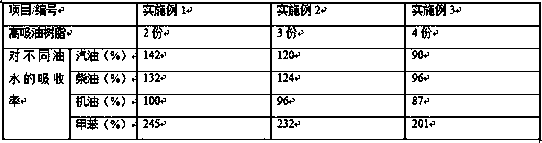

Embodiment 1

[0020] A water-swellable rubber, prepared from the following raw materials in parts by weight: 100 parts of EPDM rubber, 50 parts of carbon black, 5 parts of zinc oxide, 1 part of stearic acid, 0.8 parts of sulfur, accelerator CZ 2.5 parts, 0.4 parts of accelerator TT, 2 parts of anti-aging agent RD, 5 parts of calcium oxide, 3 parts of super oil-absorbing resin.

[0021] The preparation method is as follows: put the EPDM rubber into a Φ130mm×300mm type open mill for mastication, and after the surface of the rubber material is smooth, add carbon black, zinc oxide, anti-aging agent RD, calcium oxide, and accelerator CZ in order to promote Agent TT to prepare a mixture. A super oil-absorbing resin was added to the prepared mixed material, and further kneaded to obtain a mixed material. Add sulfur to the prepared mixed material, make triangular bags, roll, and knead the rubber material evenly. After the prepared rubber material is parked for 15-18 hours, it is scorched and vulc...

Embodiment 2

[0023] A water-swellable rubber, prepared from the following raw materials in parts by weight: 100 parts of EPDM rubber, 50 parts of carbon black, 5 parts of zinc oxide, 1 part of stearic acid, 0.8 parts of sulfur, accelerator CZ 2.5 parts, 0.4 parts of accelerator TT, 2 parts of anti-aging agent RD, 5 parts of calcium oxide, 3 parts of super oil-absorbing resin.

[0024] A water-swellable rubber was prepared in the same manner as in Example 1.

Embodiment 3

[0026] A water-swellable rubber, prepared from the following raw materials in parts by weight: 100 parts of EPDM rubber, 50 parts of carbon black, 5 parts of zinc oxide, 1 part of stearic acid, 0.8 parts of sulfur, accelerator CZ 2.5 parts, accelerator TT0.4 parts, anti-aging agent RD 2 parts, calcium oxide 5 parts, super oil-absorbing resin 4 parts.

[0027] A water-swellable rubber was prepared in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com