High-elasticity modified epoxy resin grouting material for stopping leakage and preparation method of high-elasticity modified epoxy resin grouting material

A technology of epoxy resin grouting and epoxy resin, which is applied in the field of building materials, can solve the problems of poor elasticity of the consolidated body and the failure to achieve the plugging effect, and achieve the effect of increasing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a modified epoxy resin grouting material for high elasticity plugging and a preparation method thereof.

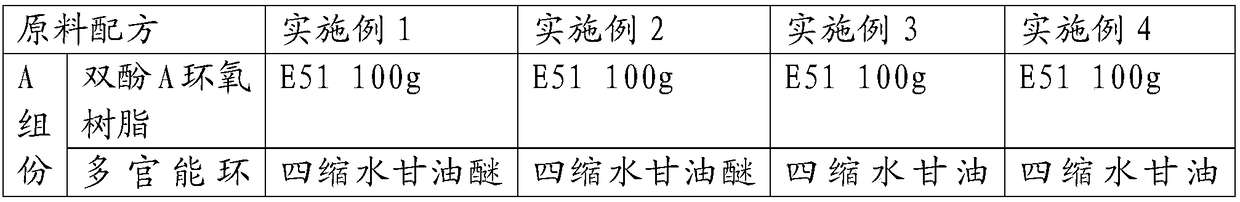

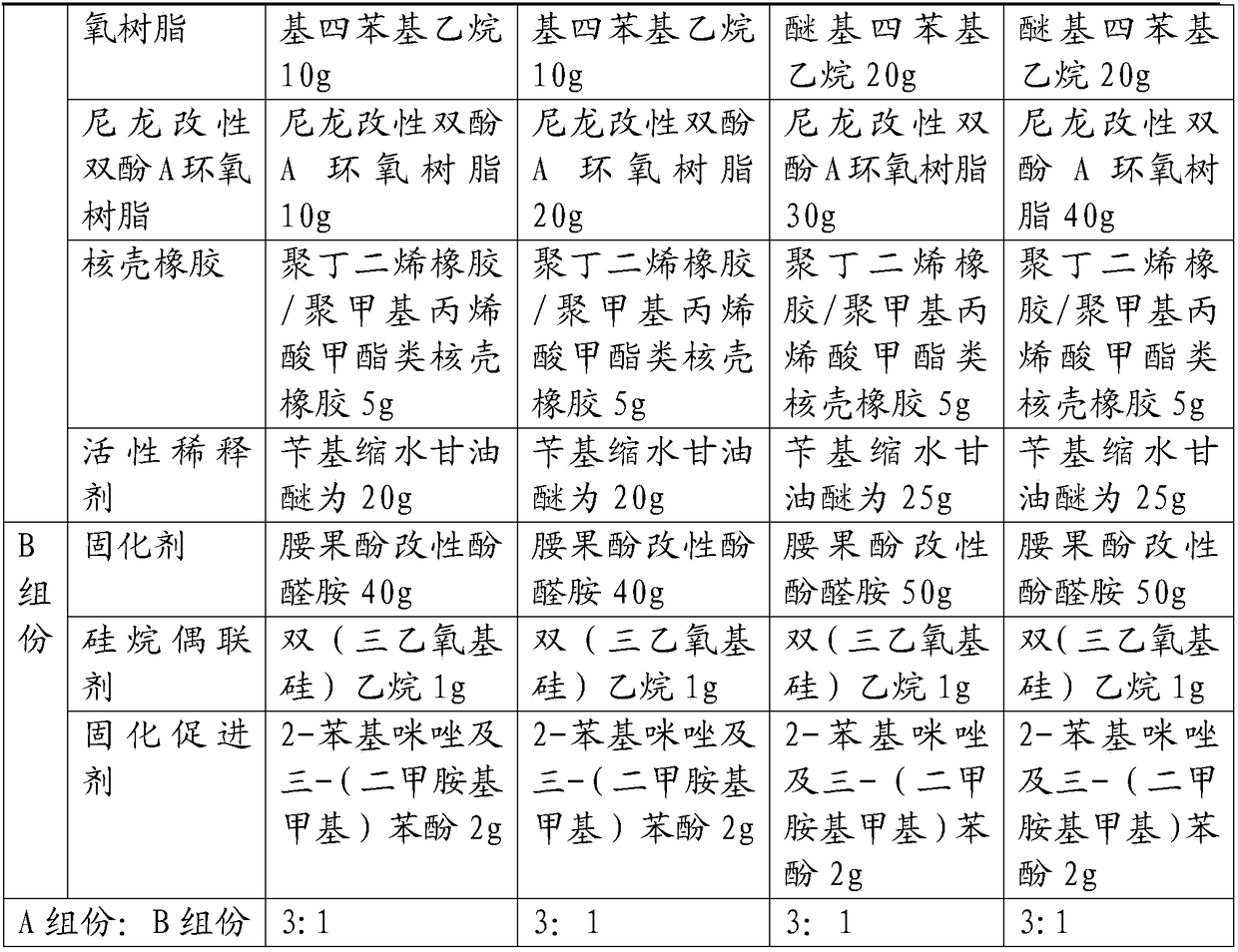

[0036] The raw material formula of the modified epoxy resin grouting material for high elasticity plugging is shown in Table 1.

[0037] The preparation steps of modified epoxy resin grouting material for high elasticity plugging are as follows:

[0038] A component by mass parts bisphenol A epoxy resin E51 100g, tetraglycidyl ether-based tetraphenylethane 10g, nylon modified bisphenol A epoxy resin 10g, polybutadiene rubber / polymethylmethacrylate 5g ester core-shell rubber, 20g benzyl glycidyl ether, stir well;

[0039] For component B, add 40 g of cardanol modified phenalkamine, 1 g of bis(triethoxysilyl)ethane, 2 g of 2-phenylimidazole and tris-(dimethylaminomethyl)phenol according to mass parts, and stir well.

[0040] When plugging building defects, mix component A and component B in a mass fraction ratio of 3:1, and stir evenly to obtain a cons...

Embodiment 2

[0042] This embodiment provides a modified epoxy resin grouting material for high elasticity plugging and a preparation method thereof.

[0043] The raw material formula of the modified epoxy resin grouting material for high elasticity plugging is shown in Table 1.

[0044] The preparation steps of modified epoxy resin grouting material for high elasticity plugging are as follows:

[0045] A component by mass parts bisphenol A epoxy resin E51 100g, tetraglycidyl ether-based tetraphenylethane 10g, nylon modified bisphenol A epoxy resin 10g, polybutadiene rubber / polymethylmethacrylate 5g ester core-shell rubber, 20g benzyl glycidyl ether, stir well;

[0046] For component B, add 40 g of cardanol modified phenalkamine, 1 g of bis(triethoxysilyl)ethane, 2 g of 2-phenylimidazole and tris-(dimethylaminomethyl)phenol according to mass parts, and stir well.

[0047] When plugging building defects, mix component A and component B in a mass fraction ratio of 3:1, and stir evenly to obtain a cons...

Embodiment 3

[0049] This embodiment provides a modified epoxy resin grouting material for high elasticity plugging and a preparation method thereof.

[0050] The raw material formula of the modified epoxy resin grouting material for high elasticity plugging is shown in Table 1.

[0051] The preparation steps of modified epoxy resin grouting material for high elasticity plugging are as follows:

[0052] A component by mass parts bisphenol A epoxy resin E51 100g, tetraglycidyl ether tetraphenylethane 20g, nylon modified bisphenol A epoxy resin 10g, polybutadiene rubber / polymethylmethacrylate 5g ester core-shell rubber, 25g benzyl glycidyl ether, stir well;

[0053] For component B, add 50 g of cardanol modified phenalkamine, 1 g of bis(triethoxysilyl)ethane, 2 g of 2-phenylimidazole and tris-(dimethylaminomethyl)phenol in parts by mass, and stir well.

[0054] When plugging building defects, mix component A and component B in a mass fraction ratio of 3:1, and stir evenly to obtain a consolidated body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com