UV embossed ink composition and preparation method thereof

An ink composition, glycerin technology, applied in ink, household appliances, applications, etc., can solve the problem of easy cracking in the process, and achieve the effect of reducing the cracking problem of the ink layer, stable performance, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

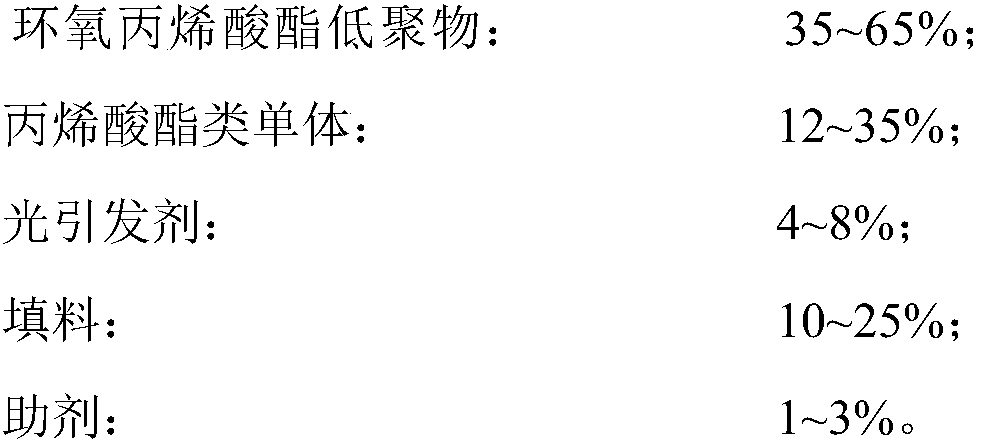

Method used

Image

Examples

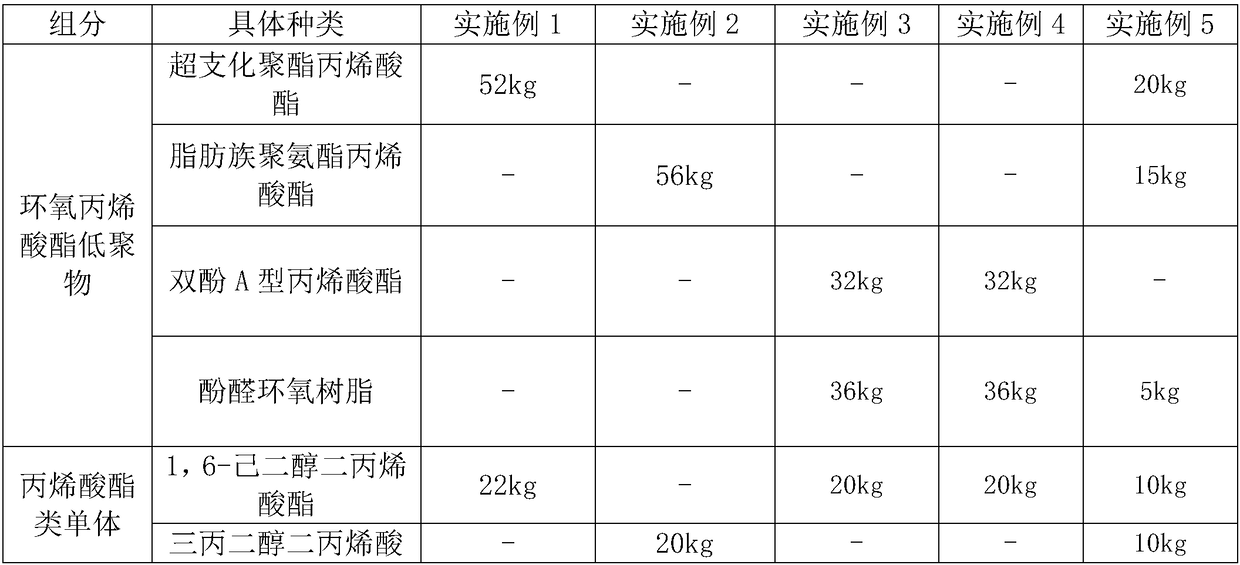

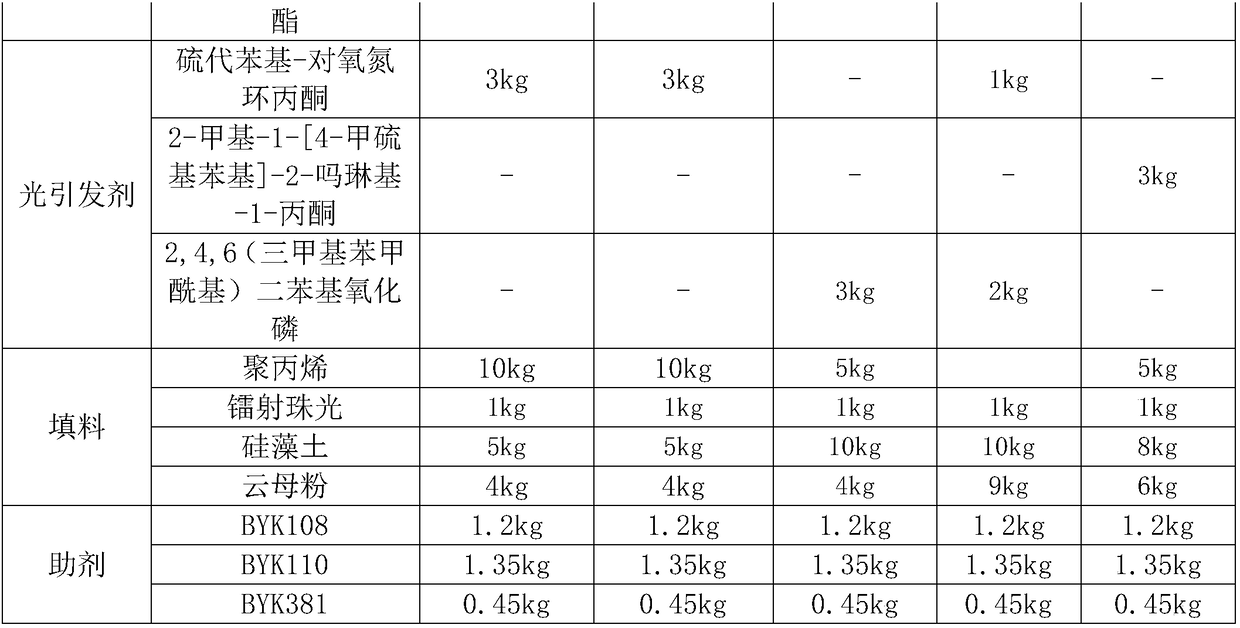

Embodiment 1~5

[0023] 1. Weigh the ingredients: Weigh each raw material according to the formula in Table 1 and place them in different stainless steel barrels for later use;

[0024] 2. The initiator is dissolved in the monomer, add the initiator, heat at constant temperature until the initiator is completely dissolved, and continue to stir at constant temperature for 1 hour;

[0025] 3. Dispersion: After the initiator is fully dissolved, add the remaining ingredients, place it on a mechanical high-speed stirrer, stir for 1 hour, fully stir it evenly, and let it stand for a while. After the system is stable, the prepared UV embossed ink .

[0026] Table 1

[0027]

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com