Preparation method of multifunctional toilet soap

A multi-functional soap technology, applied in the field of daily chemicals, can solve the problems of poor antibacterial and odor-removing properties of soap, volatile active ingredients, and single function, so as to improve water replenishment capacity, antibacterial property, The effect of improving the detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

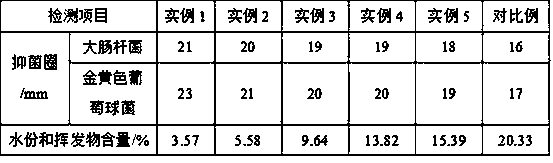

Examples

example 1

[0020]Mix sepiolite and water at a mass ratio of 1:8, soak for 30 minutes at a temperature of 45°C and a rotational speed of 380r / min, and then filter to obtain a pretreated sepiolite. Stone and aloe vera gel are mixed at a mass ratio of 1:5, and honey with a mass of 0.6 times the pretreated sepiolite is added to the mixture of pretreated sepiolite and aloe vera gel at a temperature of 55°C and a rotational speed of 300r Under the condition of stirring and mixing for 55 minutes, filter to obtain a filter cake, move the filter cake into a drying oven, and dry it at a constant temperature for 55 minutes at a temperature of 75°C to obtain 2 times pretreated sepiolite. Treated sepiolite and vaseline were mixed and added to the ball mill, and zirconia ball milling beads with 5 times the mass of pretreated sepiolite were added to the ball mill twice, and after ball milling and mixing for 25 minutes, modified sepiolite was obtained; grapefruit peel fibers were added to steam In the e...

example 2

[0022] Put the pomelo peel fiber into the steam explosion tank, and feed water vapor into the steam explosion tank at a rate of 60mL / min until the pressure inside the tank is 3.4MPa. After 15 minutes of pressure-holding treatment, open the valve at the bottom of the tank to release the pressure instantly, and get Thin grapefruit peel fibers, move the fine grapefruit peel fibers into a carbonization furnace, and carbonize at a temperature of 700°C under nitrogen protection conditions for 50 minutes at a constant temperature to obtain carbonized grapefruit peel fibers. Carbonize grapefruit peel fibers and stainless steel beads at a mass ratio of 1 : 4 mixed, and to the mixture of carbonized pomelo peel fiber and stainless steel beads, add milk with 0.4 times the mass of carbonized pomelo peel fiber and spider silk degradation solution with 0.4 times the mass of carbonized pomelo peel fiber, at a temperature of 55 ° C, a rotating speed of 300 r / Under the condition of in, stir and...

example 3

[0024] Mix sepiolite and water at a mass ratio of 1:8, soak for 30 minutes at a temperature of 45°C and a rotational speed of 380r / min, and then filter to obtain a pretreated sepiolite. Stone and aloe vera gel are mixed at a mass ratio of 1:5, and honey with a mass of 0.6 times the pretreated sepiolite is added to the mixture of pretreated sepiolite and aloe vera gel at a temperature of 55°C and a rotational speed of 300r Under the condition of stirring and mixing for 55 minutes, filter to obtain a filter cake, move the filter cake into a drying oven, and dry it at a constant temperature for 55 minutes at a temperature of 75°C to obtain 2 times pretreated sepiolite. Treated sepiolite and vaseline were mixed and added to the ball mill, and zirconia ball milling beads with 5 times the mass of pretreated sepiolite were added to the ball mill twice, and after ball milling and mixing for 25 minutes, modified sepiolite was obtained; grapefruit peel fibers were added to steam In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com