Preparation method of oligopeptide powder of marine-fish collagen and application thereof

A technology of oligopeptide and fish collagen, which is applied in the field of food processing, can solve the problems of waste of nutrients and other problems, and achieve the effects of reducing waste, delaying aging and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

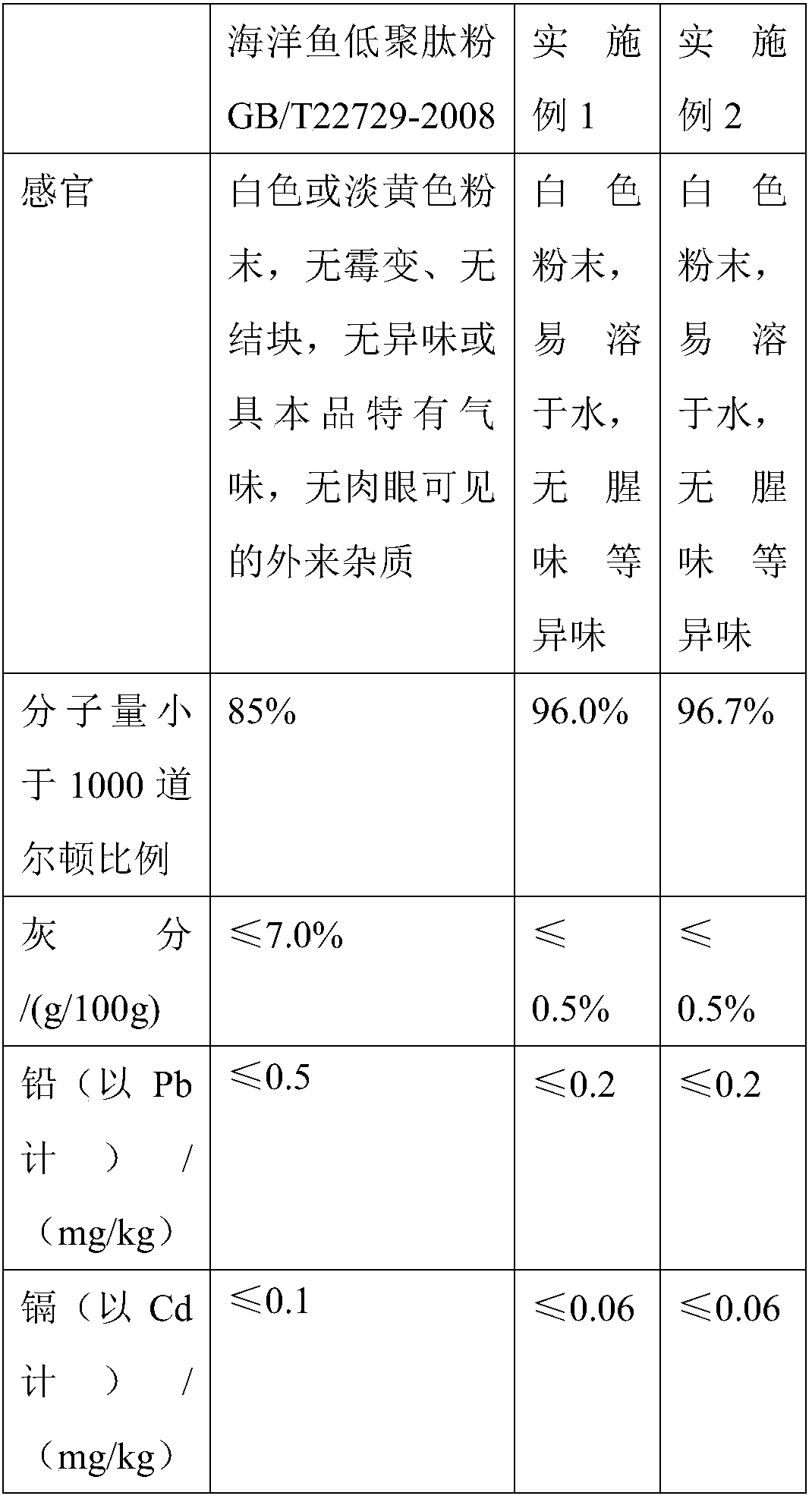

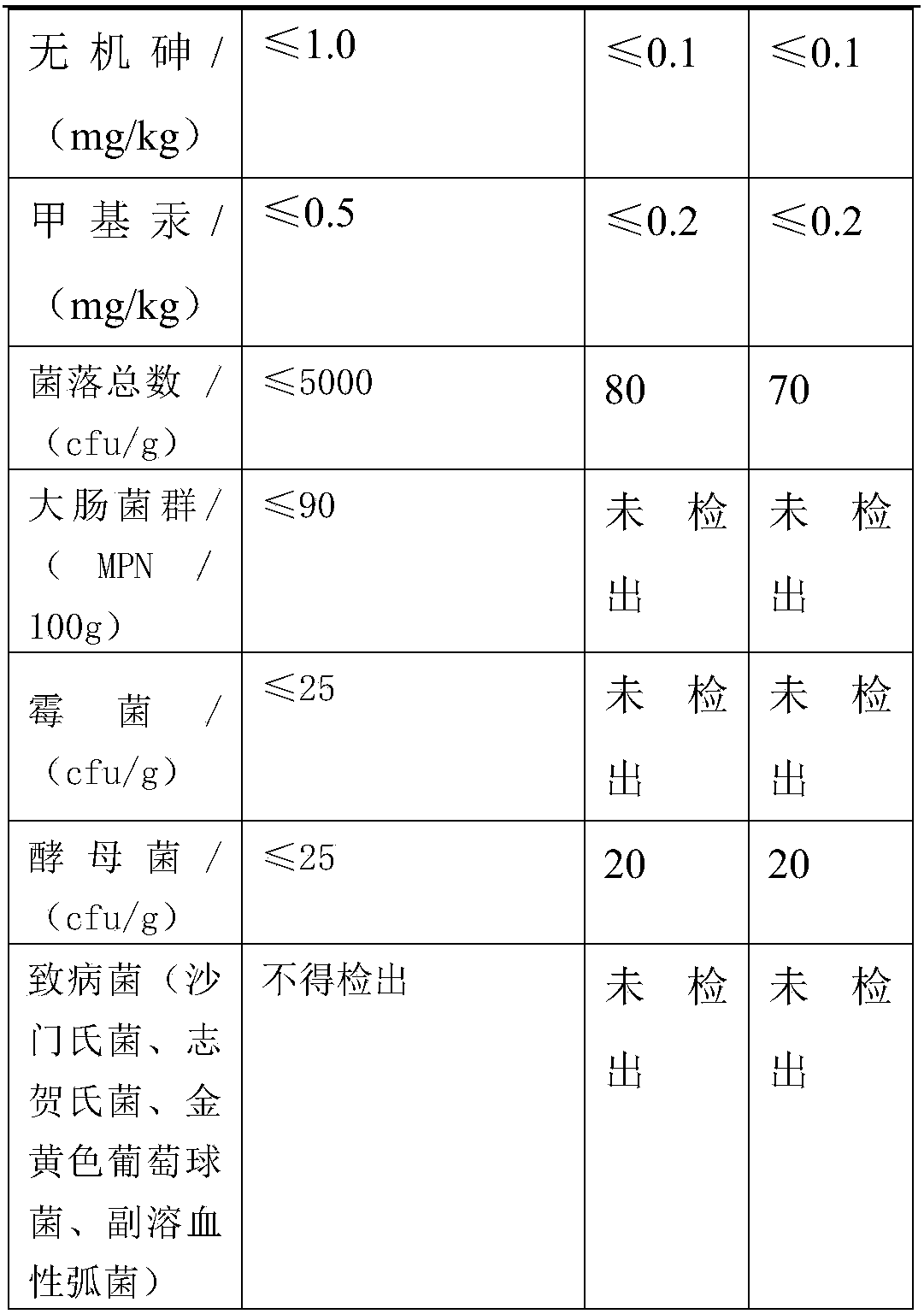

Examples

Embodiment 1

[0043] Marine fish collagen oligopeptide powder is prepared according to the following steps:

[0044] (1) Cleaning: Use food grade 0.1%-0.3% food grade sodium hydroxide and salt to wash the fish skin for 2-4 hours according to the ratio of material to liquid ratio of 1:3, drain the water, and then wash it with tap water for about 8 times , wash until the water is translucent and colorless, and the pH is around 9, set aside;

[0045] (2) Gel extraction: After feeding, add high-temperature water according to the production instructions, adjust the pH to 6, and extract the gel at 75°C;

[0046] (3) Filtration and standing: filter the material liquid after the rubber extraction through a triangular filter sieve and then put it in the clarification tank for 2-4 hours, and then discharge and filter after stratification;

[0047] (4) Cotton cake filtration: the supernatant is filtered through a cotton cake filter, the entire filtration pressure is controlled at 0.2MPa, and the turb...

Embodiment 2

[0059] As a preferred solution, the marine fish collagen oligopeptide powder of the present invention is prepared according to the following steps:

[0060] (1) Cleaning: Use food grade 0.1%-0.3% food grade sodium hydroxide and salt to wash the fish skin for 2-4 hours according to the ratio of material to liquid ratio of 1:3, drain the water, and then wash it with tap water for about 8 times , wash until the water is translucent and colorless, and the pH is around 9, set aside;

[0061] (2) Gel extraction: After feeding, add high-temperature water according to the production instructions, adjust the pH to 6, and extract the gel at 75°C;

[0062] (3) Filtration and standing: filter the material liquid after the rubber extraction through a triangular filter sieve and then put it in the clarification tank for 2-4 hours, and then discharge and filter after stratification;

[0063] (4) Cotton cake filtration: the supernatant is filtered through a cotton cake filter, the entire fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com