Recovery method for anode material of nickel cobalt manganese waste battery

A technology for waste batteries and positive electrode materials, which is applied in the direction of recycling by waste collectors, etc., can solve the problems of complex ternary material technology, and achieve the effects of cost reduction, high capacity retention rate, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

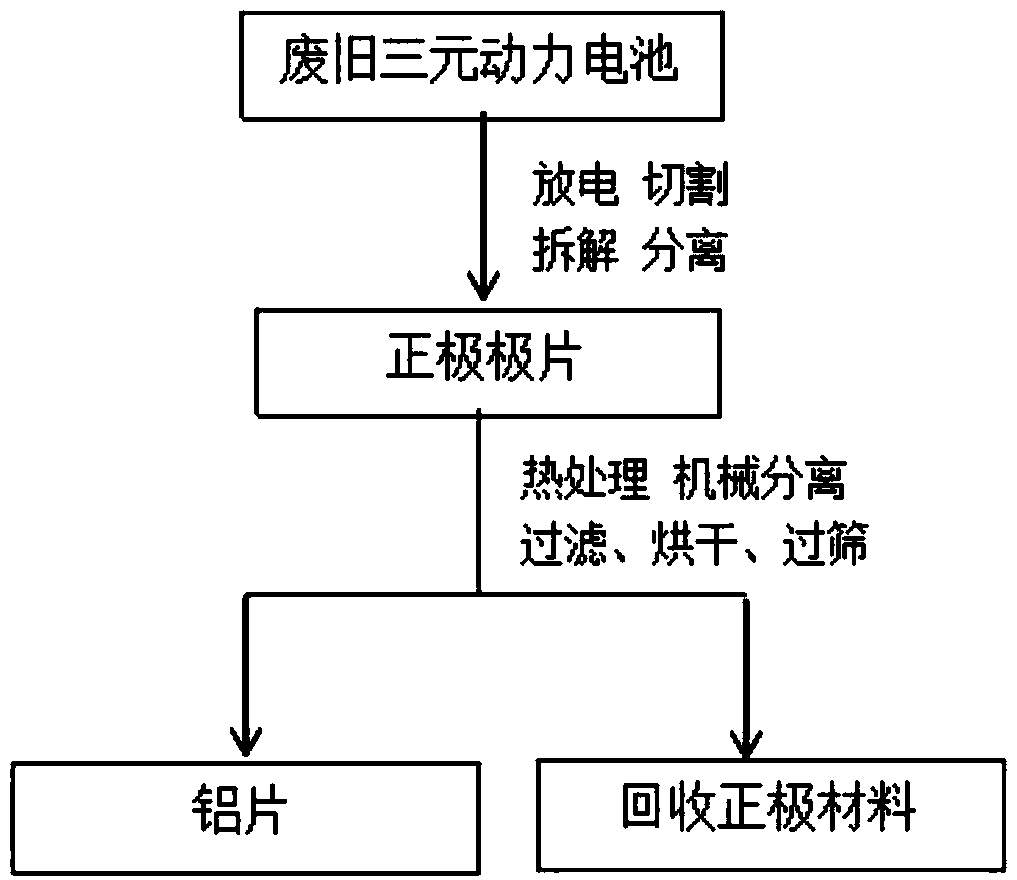

Embodiment 1

[0043] according to figure 1The flow chart is shown for the recovery of cathode materials. Weld the ternary waste power battery to the tabs, connect the diode to fully discharge, then cut, disassemble, and separate the battery to obtain the positive pole piece; soak the positive pole piece in DMC for 3 minutes, remove the pole piece and dry it naturally, Sinter in a muffle furnace at 400°C for 150 minutes in an air atmosphere; take 20g of the sintered pole piece and put it in 200mL of alcohol in a 500mL ball mill pot, use a total of 120g of zirconia beads with a diameter of about 3mm, and mix and ball mill at a speed of 40rmp 120 minutes; filter and recover alcohol to obtain a mixture of aluminum flakes and positive electrode materials; pass through a 400-mesh sieve after drying to obtain 14.0847g of positive electrode materials recovered; place the recovered aluminum flakes in 1mol / L sodium hydroxide solution for use It was completely dissolved, and a total of 0.9405 g of th...

Embodiment 2

[0051] according to figure 1 The flow chart is shown for the recovery of cathode materials. Weld the ternary waste power battery to the tabs, connect the diode to fully discharge, then cut, disassemble, and separate the battery to obtain the positive pole piece; soak the positive pole piece in DMC for 3 minutes, remove the pole piece and dry it naturally, Sinter in a muffle furnace at 500°C for 120 minutes in an air atmosphere; take 21g of the sintered pole piece and put it in 200mL of tap water in a 500mL ball mill, use a total of 80g of zirconia beads with a diameter of about 8mm, and mix the ball mill at a speed of 30rmp 120 minutes; filter and recover tap water to obtain a mixture of aluminum flakes and positive electrode materials; pass through a 400-mesh sieve after drying to obtain 14.3780 g of positive electrode materials recovered; place the recovered aluminum flakes in 1mol / L sodium hydroxide solution for use It was completely dissolved, and a total of 0.7076 g of t...

Embodiment 3

[0053] according to figure 1 The flow chart is shown for the recovery of cathode materials. Weld the ternary waste power battery to the tabs, connect the diode to fully discharge, then cut, disassemble, and separate the battery to obtain the positive pole piece; soak the positive pole piece in DMC for 3 minutes, remove the pole piece and dry it naturally, Sinter in a muffle furnace at 450°C for 120 minutes in an oxygen atmosphere; take 20g of the sintered pole piece and pour it into a 500mL ball mill in 200mL of tap water, use a total of 150g of zirconia beads with a diameter of about 8mm, and mix the ball mill at a speed of 25rmp 120 minutes; filter and recover tap water to obtain a mixture of aluminum flakes and positive electrode materials; pass through a 400-mesh sieve after drying to obtain 14.9847g of positive electrode materials recovered; place the recovered aluminum flakes in 1mol / L sodium hydroxide solution for use It was completely dissolved, and a total of 0.5975 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com