Preparation method for environmentally-friendly plant type cotton fiber fixing agent

A plant-based, color-fixing agent technology, applied in the field of fabric materials, can solve the problems of natural color-fixing agent residues, harmful substances, decomposing the human body and the environment, etc., to improve the bonding strength, color fastness, and color fastness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

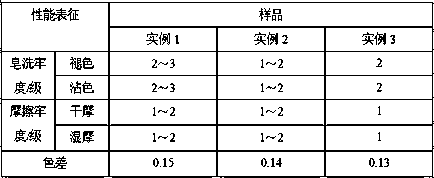

Examples

example 1

[0018] Take the apple pomace and soak it in deionized water for 25 minutes according to the mass ratio of 1:5, soften the tissue and crush it for 3 minutes, heat it in an oil bath at 100°C for 10 minutes, filter the filter cake and dry it at 75°C until it contains water The ratio is 50%, to obtain dried apple pomace, then add the dried apple pomace to deionized water according to the mass ratio of 1:5, adjust the pH to 2.5 with 3% hydrochloric acid, heat in a water bath at 75°C for 2 hours, and centrifuge And collect the supernatant, rotary evaporate at 45 ℃ to 1 / 6 of the supernatant, get the concentrated solution and let it stand to cool to room temperature, according to the volume ratio 1:1, mix the concentrated solution with absolute ethanol and let it stand After settling for 3 hours, collect the lower layer of sediment and vacuum freeze-dry to obtain modified particles; according to the mass ratio of 1:25, mix cutinase and Lycopodium spore powder and put them in a ball mil...

example 2

[0020] Take the apple pomace and soak it in deionized water for 27 minutes according to the mass ratio of 1:5, soften the tissue and crush it for 4 minutes, heat it in an oil bath at 110°C for 12 minutes, filter the filter cake and dry it at 77°C until it contains water The ratio is 50%, to obtain dried apple pomace, then according to the mass ratio of 1:5, add the dried apple pomace to deionized water, adjust the pH to 2.5 with 3% hydrochloric acid, heat in a water bath at 82°C for 2 hours, and centrifuge And collect the supernatant, rotary evaporate at 47 ℃ to 1 / 6 of the supernatant, get the concentrated solution and let it stand to cool to room temperature, according to the volume ratio of 1:1, mix the concentrated solution with absolute ethanol and let it stand After settling for 4 hours, collect the lower precipitate and vacuum freeze-dry to obtain modified particles; mix the cutinase and Lycopodium spore powder in a mass ratio of 1:25 and place them in a ball milling tank...

example 3

[0022] Take the apple pomace and soak it in deionized water for 27 minutes according to the mass ratio of 1:5, soften the tissue and crush it for 4 minutes, heat it in an oil bath at 110°C for 12 minutes, filter the filter cake and dry it at 77°C until it contains water The ratio is 50%, to obtain dried apple pomace, then add the dried apple pomace to deionized water according to the mass ratio of 1:5, adjust the pH to 2.5 with 3% hydrochloric acid, heat in a water bath at 83°C for 2 hours, and centrifuge And collect the supernatant, rotary evaporate at 47 ℃ to 1 / 6 of the supernatant, get the concentrated solution and let it stand to cool to room temperature, according to the volume ratio of 1:1, mix the concentrated solution with absolute ethanol and let it stand After settling for 4 hours, collect the lower precipitate and vacuum freeze-dry to obtain modified particles; mix the cutinase and Lycopodium spore powder in a mass ratio of 1:25 and place them in a ball milling tank,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com