Graphite boat saturation technology of solar cell

A technology of solar cells and graphite boats, applied in the field of solar cells, can solve the problems of large color difference and short service life of graphite boats, and achieve the effects of improving the quality rate, good color consistency and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention provides a graphite boat saturation process of a solar cell, comprising the steps of:

[0022] S1. Removing the silicon nitride layer: use 15% hydrofluoric acid solution to remove the silicon nitride layer coated on the graphite boat, and the cleaning time is 4 hours;

[0023] S2. Rinsing: Use pure water to rinse the graphite boat, rinse 4 times for 8 hours and spray for each rinse, rinse for 1 hour for the first time, rinse for 2 hours for the second time, rinse for 2 hours for the third time, and rinse for the third time Rinse for 3 hours;

[0024] S3. Drying: Dry the cleaned graphite boat in an oven, the drying temperature is 100 degrees, and the drying time is set for 8 hours;

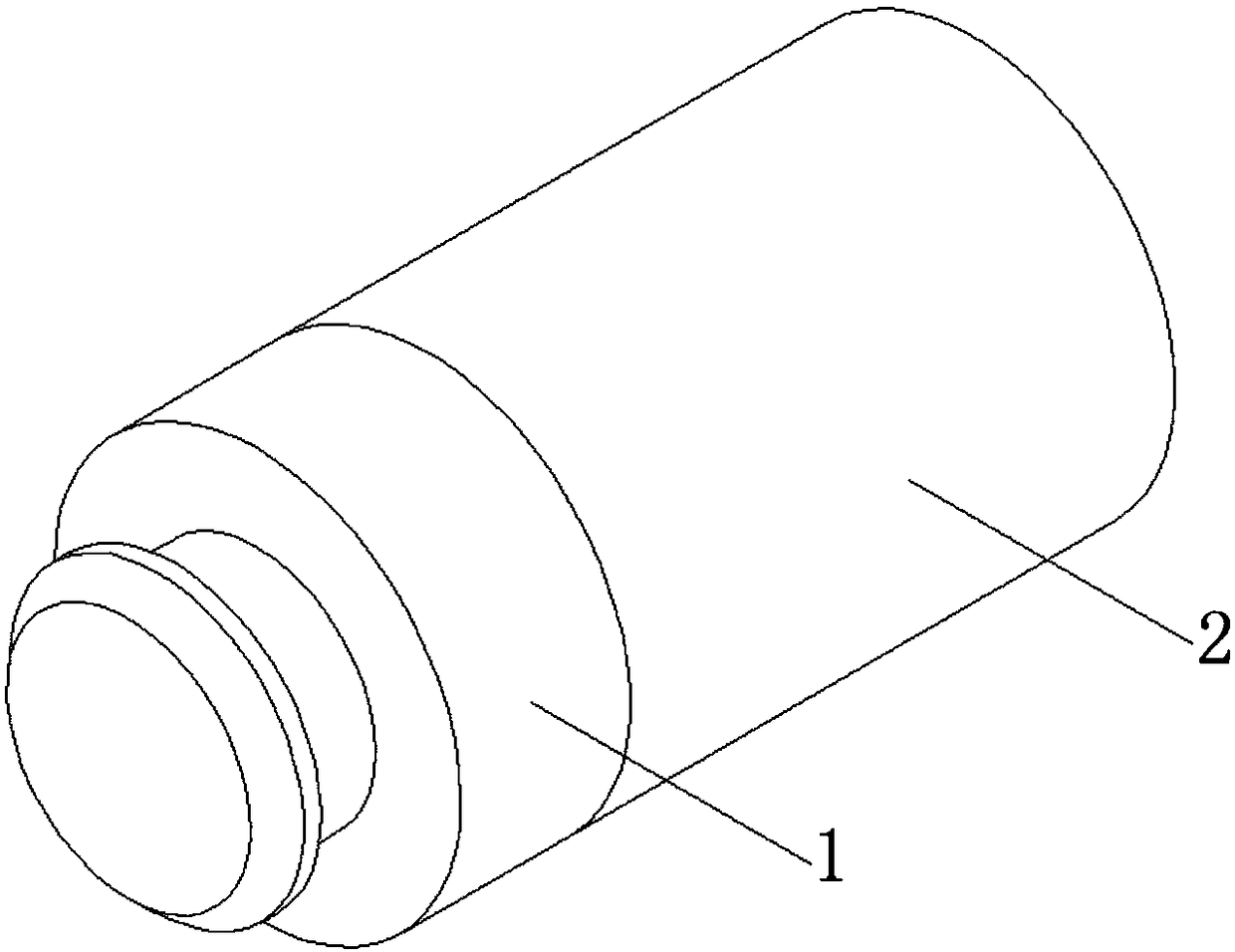

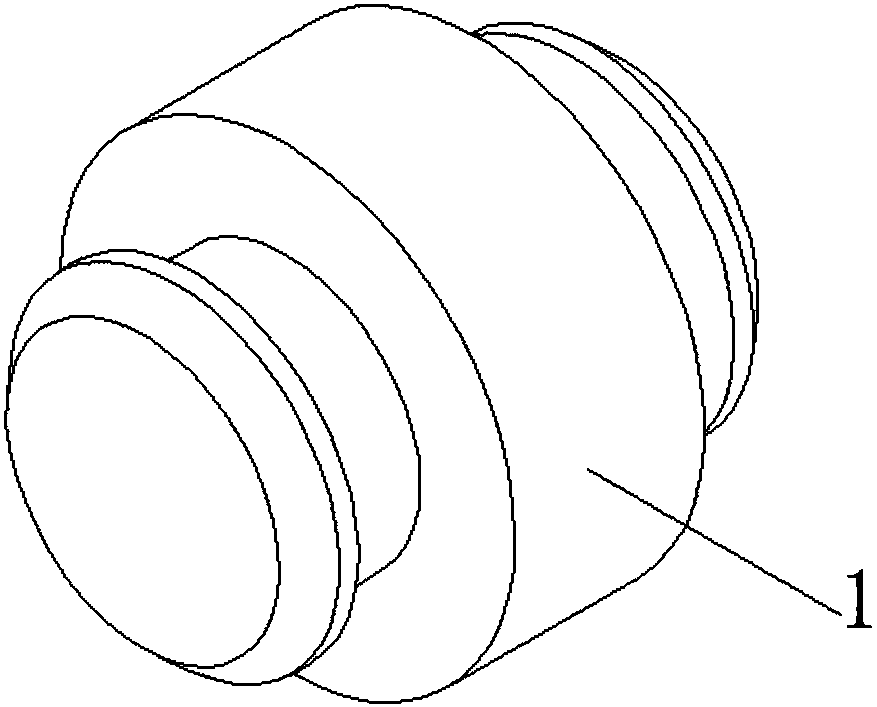

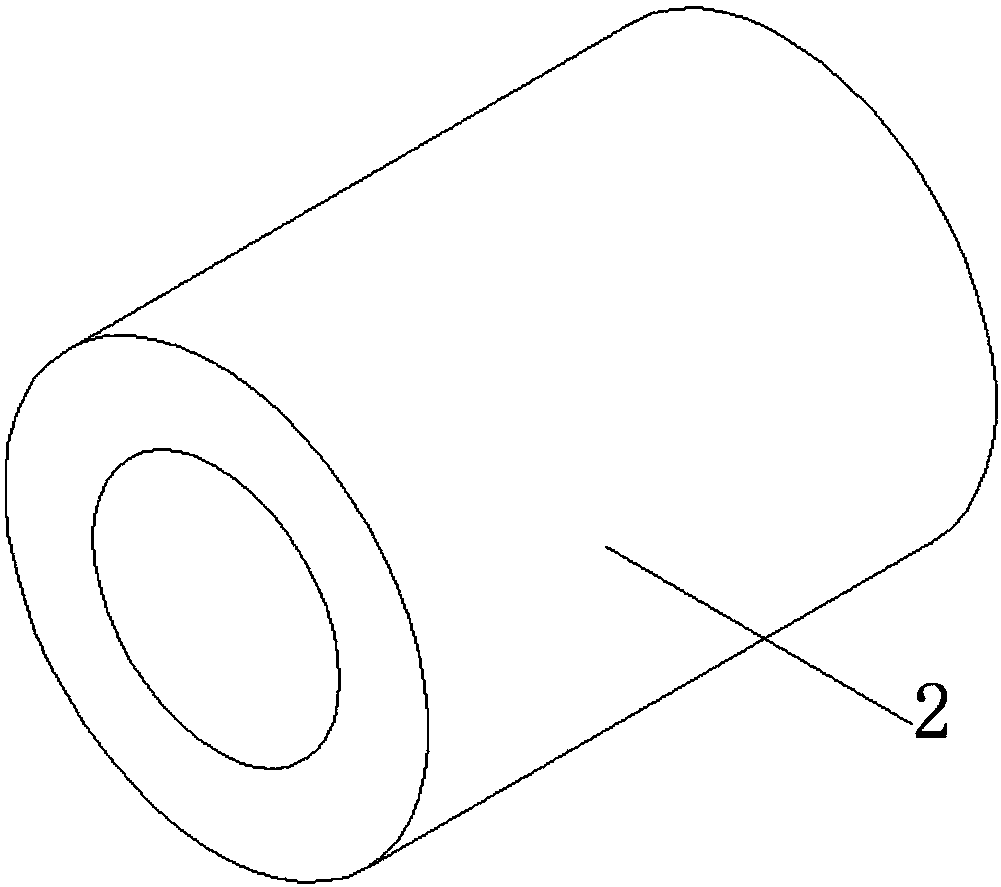

[0025] S4. Assembling: Assemble the graphite boat and install the stuck point protection component. Cover the graphite boat stuck point with the inner diameter of the ceramic stuck point protection component. In this way, all graphite stuck points 1 are protected, and the cera...

Embodiment 2

[0029] The invention provides a graphite boat saturation process of a solar cell, comprising the steps of:

[0030] S1. Removing the silicon nitride layer: use 15% hydrofluoric acid solution to remove the silicon nitride layer coated on the graphite boat, and the cleaning time is 4 hours;

[0031] S2. Rinsing: Use pure water to rinse the graphite boat, rinse 4 times for 8 hours and spray for each rinse, rinse for 1 hour for the first time, rinse for 2 hours for the second time, rinse for 2 hours for the third time, and rinse for the third time Rinse for 3 hours;

[0032] S3. Drying: Dry the cleaned graphite boat in an oven, the drying temperature is 100 degrees, and the drying time is set for 8 hours;

[0033] S4. Assembling: Assemble the graphite boat and install the stuck point protection component. Cover the graphite boat stuck point with the inner diameter of the ceramic stuck point protection component. In this way, all graphite stuck points 1 are protected, and the cera...

Embodiment 3

[0039] The invention provides a graphite boat saturation process of a solar cell, comprising the steps of:

[0040] S1. Removing the silicon nitride layer: use 15% hydrofluoric acid solution to remove the silicon nitride layer coated on the graphite boat, and the cleaning time is 4 hours;

[0041] S2. Rinsing: Use pure water to rinse the graphite boat, rinse 4 times for 8 hours and spray for each rinse, rinse for 1 hour for the first time, rinse for 2 hours for the second time, rinse for 2 hours for the third time, and rinse for the third time Rinse for 3 hours;

[0042] S3. Drying: Dry the cleaned graphite boat in an oven, the drying temperature is 100 degrees, and the drying time is set for 8 hours;

[0043] S4. Assembling: Assemble the graphite boat and install the stuck point protection component. Cover the graphite boat stuck point with the inner diameter of the ceramic stuck point protection component. According to this method, all graphite stuck points 1 are protected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com