Preparation method of nickel-cobalt-aluminum ternary material precursor with core-shell structure

A ternary material, shell-core structure technology, applied in structural parts, electrical components, nickel oxide/nickel hydroxide and other directions, can solve the problems of low tap density, large difference in precipitation pH value, poor precipitation effect, etc. The effect of good stability and high crystallinity of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

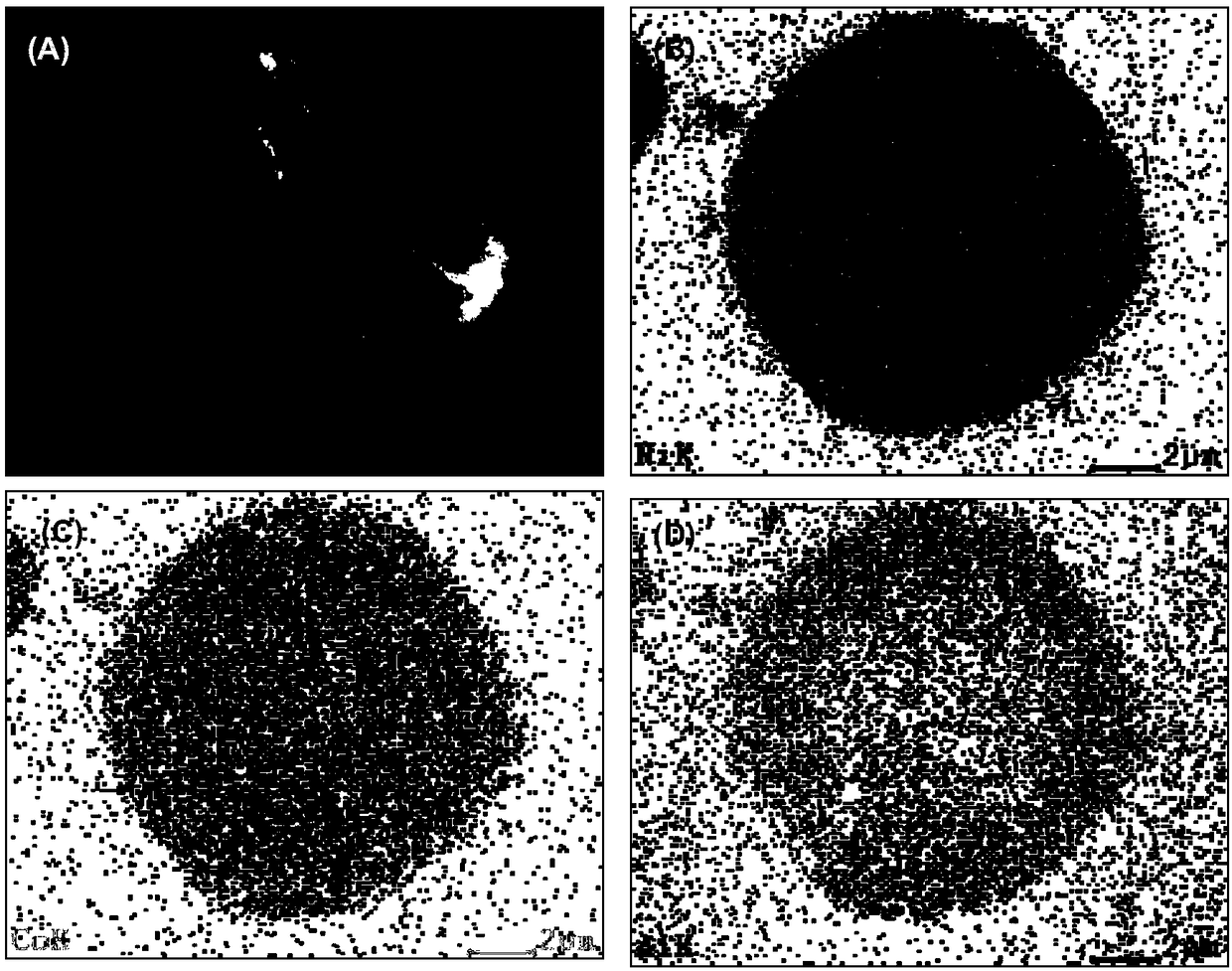

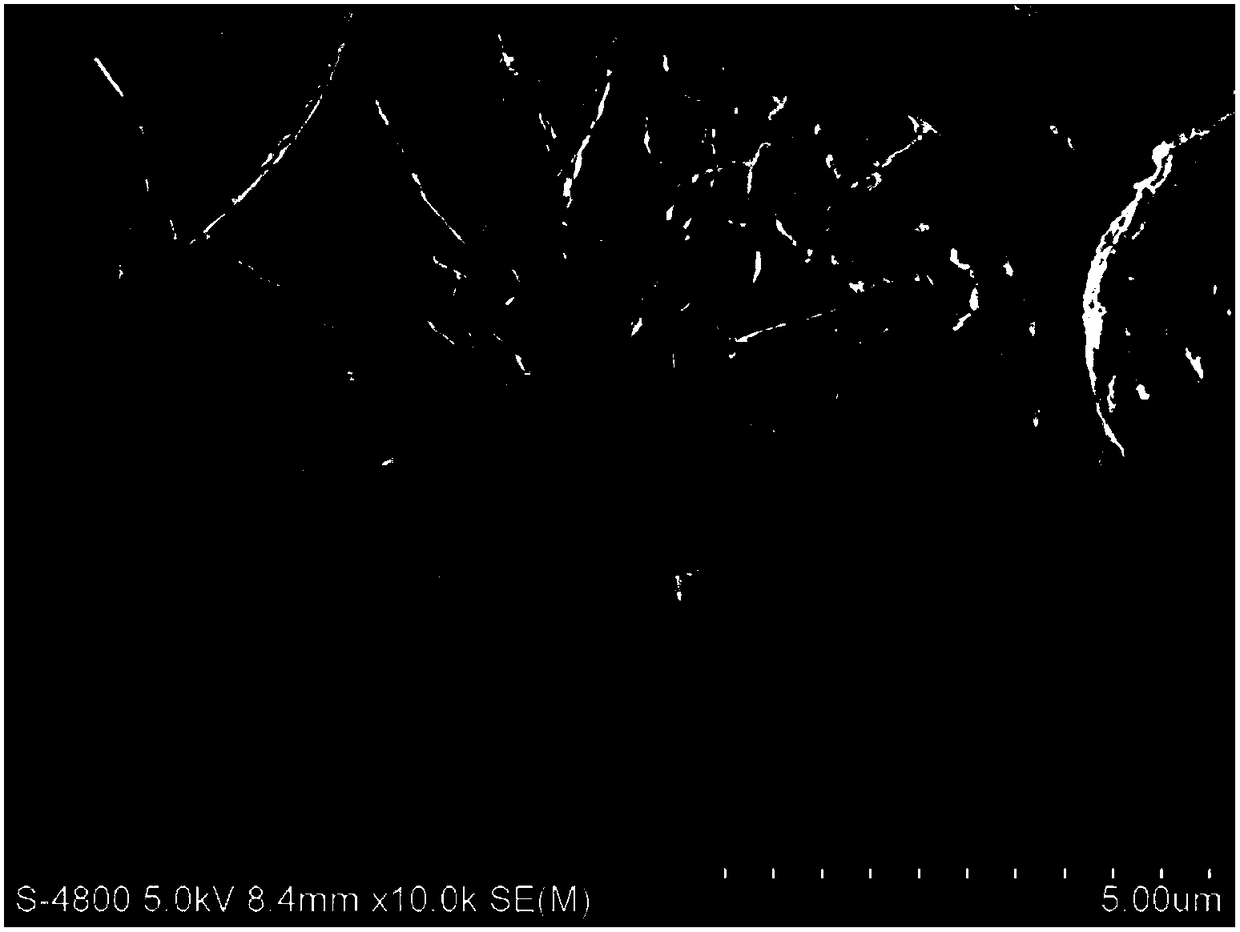

[0027] A preparation method of a core-shell structure nickel-cobalt-aluminum ternary material precursor, comprising the following steps:

[0028] Step 1: Dissolve nickel and cobalt soluble salts in deionized water in proportion, and flow them together with complexing agent A solution and precipitating agent solution into the reaction kettle equipped with bottom liquid, and set the flow rate, reaction temperature and reaction pH of each solution value and reaction time, the set reaction temperature is 45-75°C, the reaction pH value is 10.5-12.8, and the reaction time is 0.5-40h; preferably, the reaction temperature is 55-65°C, the reaction pH value is 10.8-11.8, and the reaction The time is 1-20h, forming the core structure of the material;

[0029] Among them, nickel and cobalt soluble salts include one or more of sulfate, nitrate, acetate and chloride; complexing agent A is ammonia, triethanolamine, ammonium fluoride, citric acid, oxalic acid, ethylenediamine One or several ...

Embodiment 1

[0035] Step one: configuration total metal concentration is the aqueous sulfate solution of 2mol / L nickel-cobalt, the mol ratio of nickel-cobalt is 85:13, the complexing agent A ammoniacal solution of 5.7mol / L, the sodium hydroxide solution of 4mol / L, and Add the flow into a 100L reactor whose bottom liquid is 0.3mol / L ammonia water, set the reaction temperature at 60°C, the reaction pH value at 11.5, and the reaction time for 3 hours to form the nuclear structure of the material;

[0036] Step 2: Continue the reaction in step 1, configure 0.1mol / L sodium metaaluminate aqueous solution, add it into the reaction kettle at a rate of 25mL / min, set the reaction temperature to 60°C, the reaction pH value to 11.5, and the reaction time 45h, the precipitates of nickel, cobalt and aluminum continue to grow on the core structure formed by nickel-cobalt hydroxide to form the shell structure of the material;

[0037]Step 3: Aging the product obtained in step 2 for 48 hours, centrifuging ...

Embodiment 2

[0039] Step one: configuration total metal concentration is the nitric acid aqueous solution of 2mol / L nickel-cobalt, the mol ratio of nickel-cobalt is 82:15, the complexing agent A sodium edetate solution of 0.1mol / L, the hydroxide of 10mol / L Sodium solution, and flow into the reaction kettle whose bottom liquid is 0.2mol / L ammonia water, set the reaction temperature to 45°C, the reaction pH value to 10.5, and the reaction time to 20h to form the nuclear structure of the material;

[0040] Step 2: The reaction in step 1 is continued, and the sodium metaaluminate solution of 0.01mol / L is configured, wherein the sodium metaaluminate solution is a mixture of sodium metaaluminate and 1.8 times complexing agent B sodium citrate dissolved in deionized Formed in water, added to the reaction kettle, set the reaction temperature to 45°C, the reaction pH value to 10.5, and the reaction time to 10 hours, so that the precipitates of nickel, cobalt, and aluminum continue to grow on the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com