Ternary cathode material precursor adopting core-shell structure

A cathode material and core-shell structure technology, applied in the field of ternary cathode material precursors, can solve the problems of large pH value difference, low tap density and low sphericity of the precursor, and achieve high tap density and sphericity High, predictable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Configure an aqueous solution of nickel-cobalt salt, the molar ratio of nickel-cobalt is 85:13, put it into a 100L reaction kettle in parallel with ammonia solution and sodium hydroxide solution, and react at 60°C for 30h; then add the prepared solution to the reaction kettle The sodium metaaluminate solution, continue to react for 50h, make the precipitates of nickel, cobalt and aluminum continue to grow on the nuclear structure formed by nickel-cobalt hydroxide; the nuclear structure forming the precursor is nickel-cobalt hydroxide, The shell structure is nickel-cobalt-aluminum hydroxide, the nickel in the core structure is 50% of the total nickel mass, the cobalt in the core structure is 50% of the total cobalt mass, and the molar ratio of nickel, cobalt, and aluminum in the precursor is 85 :13:2, the tap density of the precursor is 2.3g / cm 3 , particle size D 50 The particle size of the nickel cobalt hydroxide core is 12 μm, and the particle size is 7 μm.

[0021]...

Embodiment 2

[0023] Configure an aqueous solution of nickel-cobalt salt, the molar ratio of nickel-cobalt is 82:15, put it into a 100L reaction kettle in parallel with ammonia solution and sodium hydroxide solution, and react at 60°C for 60h; then add the prepared solution to the reaction kettle The sodium metaaluminate solution, continue to react for 20h, make the precipitates of nickel, cobalt, aluminum continue to grow on the nuclear structure formed by nickel-cobalt hydroxide; the nuclear structure of the precursor is nickel-cobalt hydroxide, The shell structure is nickel-cobalt-manganese hydroxide, the core structure contains 80% of the total nickel mass, and the core structure contains 80% of the total cobalt mass. The molar ratio of nickel, cobalt, and manganese in the precursor is 82 :15:3, the tap density of the precursor is 2.1g / cm 3 , particle size D 50 is 20 μm.

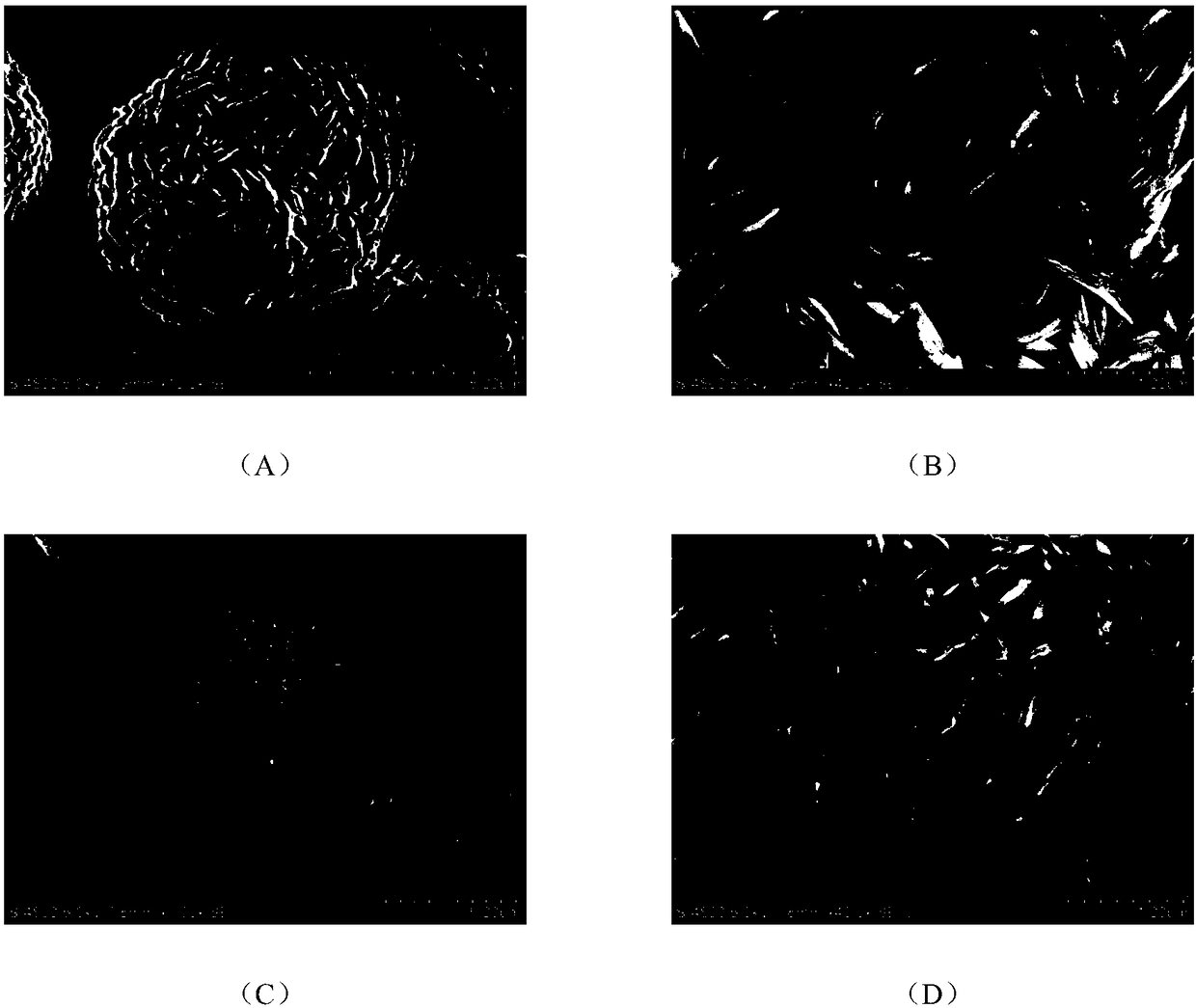

[0024] The scanning electron microscope picture of described nickel-cobalt-manganese precursor is as figure 2 s...

Embodiment 3

[0026] Configure an aqueous solution of nickel-cobalt salt, the molar ratio of nickel-cobalt is 80:10, put it into a 100L reaction kettle in parallel with ammonia solution and sodium hydroxide solution, and react at 60°C for 3 hours; then add the prepared solution to the reaction kettle The sodium metaaluminate solution, continue to react for 77h, make the precipitates of nickel, cobalt and aluminum continue to grow on the nucleus structure formed by nickel-cobalt hydroxide; the nucleus structure forming the precursor is nickel-cobalt hydroxide, The shell structure is nickel-cobalt-aluminum hydroxide, the nickel in the core is 5% of the total nickel mass, the cobalt in the core is 5% of the total cobalt mass, and the molar ratio of nickel, cobalt, and aluminum in the precursor is 80:10 :10, the precursor tap density is 1.8g / cm 3 , particle size D 50 The particle size of the nickel-cobalt hydroxide core is 6 μm.

[0027] The nickel-cobalt-aluminum ternary material precursor i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com