Crosslinking imidazole type polyether-ether-ketone anion-exchange membrane for fuel cell and preparation method thereof

An anion-exchange membrane and cross-linked imidazole-type technology, which is applied in the field of cross-linked imidazole-type anion-exchange membranes for fuel cells and its preparation, can solve the problems of commercial production impact, poor mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing a cross-linked imidazole-type polyether ether ketone anion exchange membrane for a fuel cell, comprising the following steps:

[0032] Step 1: preparing polyether ether ketone;

[0033] Step 2: performing a bromination substitution reaction on the methyl groups on the polyether ether ketone obtained in step 1 to obtain brominated polyether ether ketone;

[0034] Step 3: adding 1-methylimidazole and 1-vinylimidazole to the brominated polyether ether ketone solution in step 2 to obtain a mixed solution;

[0035] Step 4: Pour the mixed solution in Step 3 into a glass plate to dry, and the paved membrane is the cross-linked imidazole-type polyether ether ketone anion exchange membrane for fuel cells.

[0036] According to the present invention, the preparation method of the polyether ether ketone is preferably: adding methyl hydroquinone, 4,4-difluorobenzophenone, a salt-forming agent and a solvent into a reaction ...

Embodiment 1

[0042] The preparation of embodiment 1 polyether ether ketone

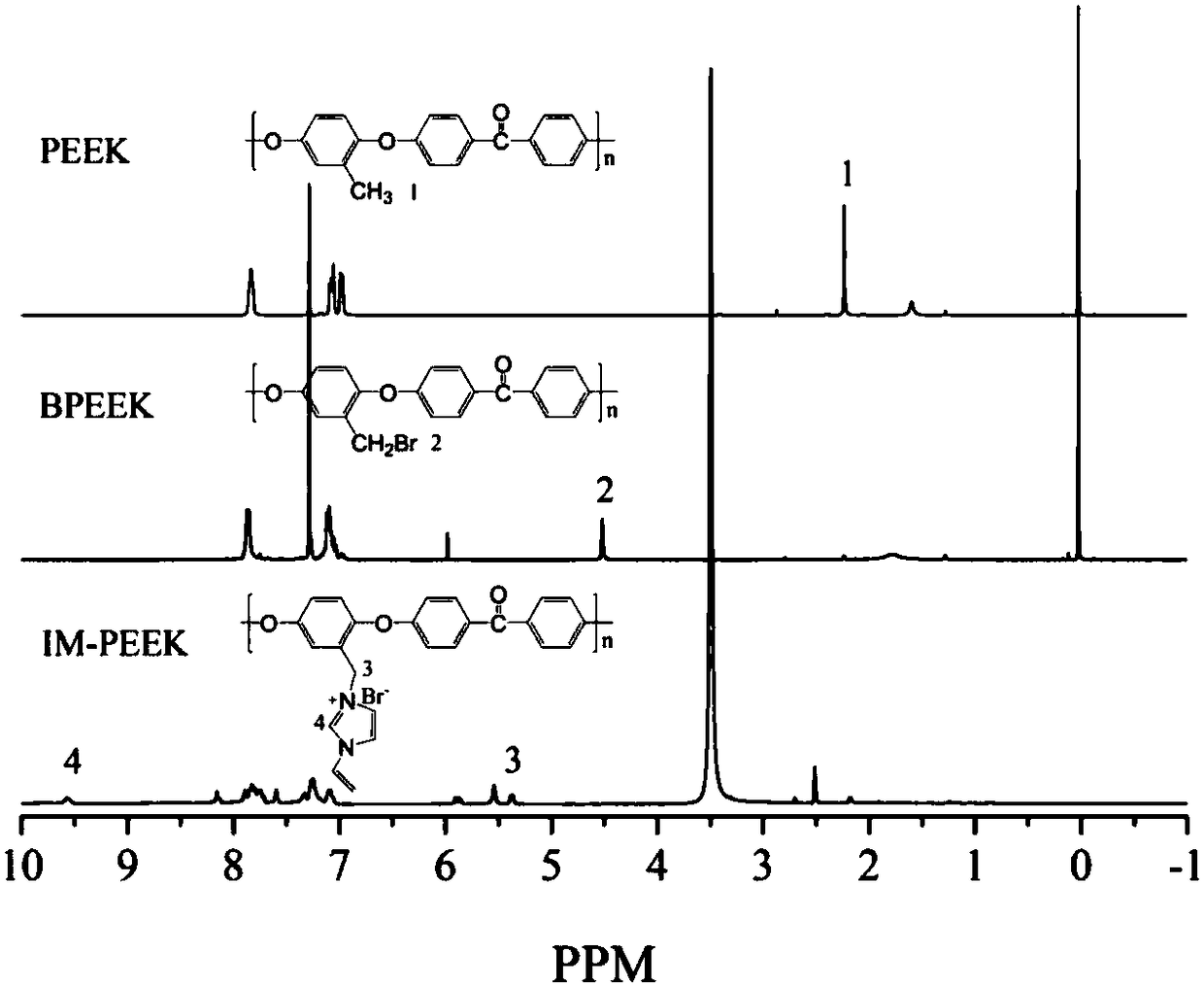

[0043] 2.483g methyl hydroquinone, 4.364g 4,4-difluorobenzophenone, 3.036g K 2 CO 3and 15ml of toluene were added into the round-bottomed flask respectively, and then the purposes of the three ports were to feed nitrogen, stir and insert the condenser successively. Heat the mixture from room temperature to 130°C under a nitrogen atmosphere, and continue to stir for 4 hours. The purpose is to completely remove the water in the system, then raise the temperature to 170°C, and continue the reaction for 5 hours. When the viscosity of the solution increases significantly, pour the solution into water, the gray polymer formed was washed 5 times with water and dried to obtain polyether ether ketone. The prepared polyetheretherketone NMR spectrum is as follows figure 1 shown.

Embodiment 2

[0044] Preparation of polyether ether ketone after embodiment 2 bromination

[0045] 1g of PEEK prepared in Example 1 and 25ml of 1,1,2,2-tetrachloroethane were respectively added to a 100ml round bottom flask, wherein the two sides of the flask were nitrogen inlet and outlet, and the middle one was used for mechanical stirring , when the polymer is completely dissolved, add 1.18g NBS and 0.08g BPO to the three-neck flask, heat the mixture under nitrogen protection, raise from normal temperature to 78°C, and react under this condition for 5h, and cool the solution to room temperature, Then pour it into ethanol under stirring. The yellow precipitate is brominated polyether ether ketone (BPEEK). Wash the precipitate 4 times with ethanol and dry it in an oven at 40-60°C for 10-12h. The prepared brominated polyetheretherketone NMR spectrum is as follows figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com