Chromium electroplating wastewater treatment system and method

A wastewater treatment system and electrochrome plating technology, applied in the field of water treatment, can solve the problems of difficult reuse of discharged water, failure to meet environmental protection requirements, and high consumption of raw materials, so as to increase flow rate, speed up heat exchange speed, and improve the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, features and effects of the present invention, the following examples are exemplified, and detailed descriptions are as follows in conjunction with the accompanying drawings.

[0018] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

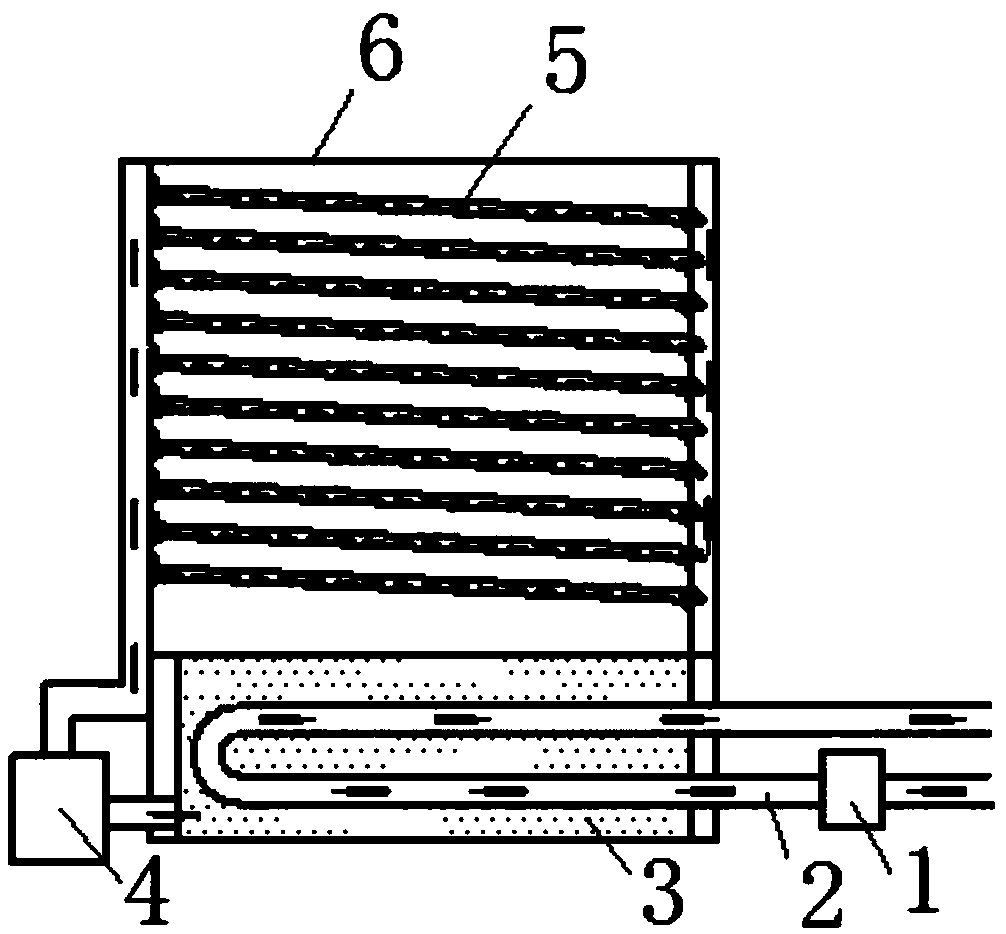

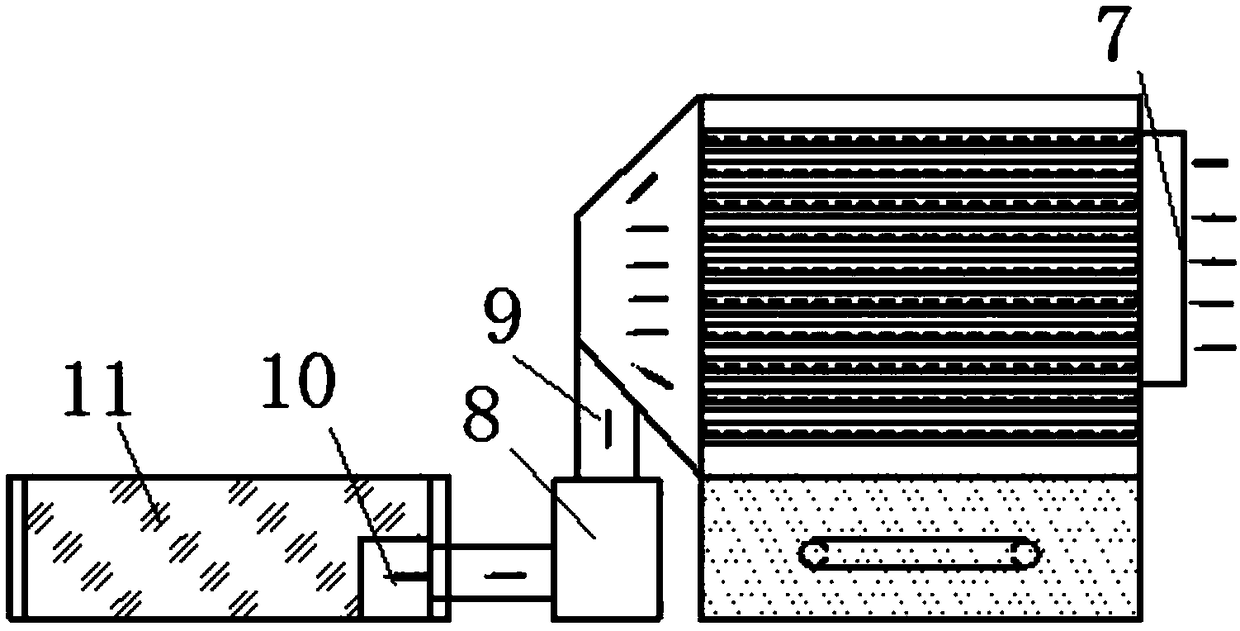

[0019] like figure 1 As shown, the electrochrome plating wastewater treatment system provided by the embodiment of the present invention includes a pipeline pump 1, a quenching medium delivery pipeline 2, an electrochrome plating wastewater storage tank 3, a water pump 4, a multi-layer grid 5, an outer cover 6, an air filter 7, Roots blower 8, steam pipeline 9, diverter 10, electroplating cleaning pool 11.

[0020] The right side of the electrochrome-plating wastewater storage pool 3 is provided with a quenching medium delivery pipeline 2; the quenching medium delivery pipeline 2 is bolted to a pipeline pump 1; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com