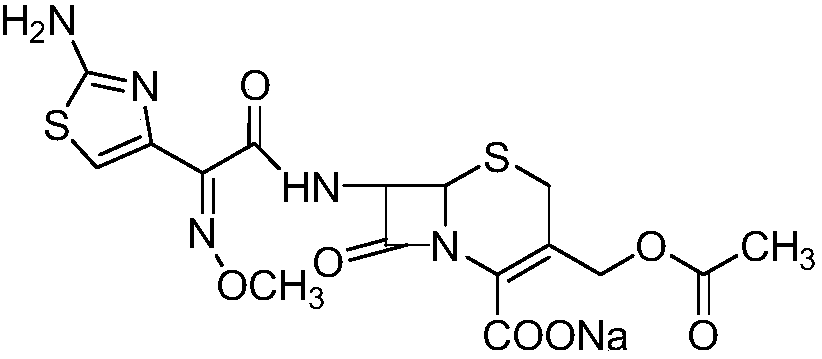

Method for preparing cefotaxime through solid-phase synthetic method

A technology for cefotaxime and solid-phase synthesis, applied in organic chemistry and other fields, can solve the problems of low total yield of cefotaxime, cumbersome operation, and low purity, and achieve the goal of improving the total yield of the reaction, simplifying the reaction procedure, and improving the purity of the product Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

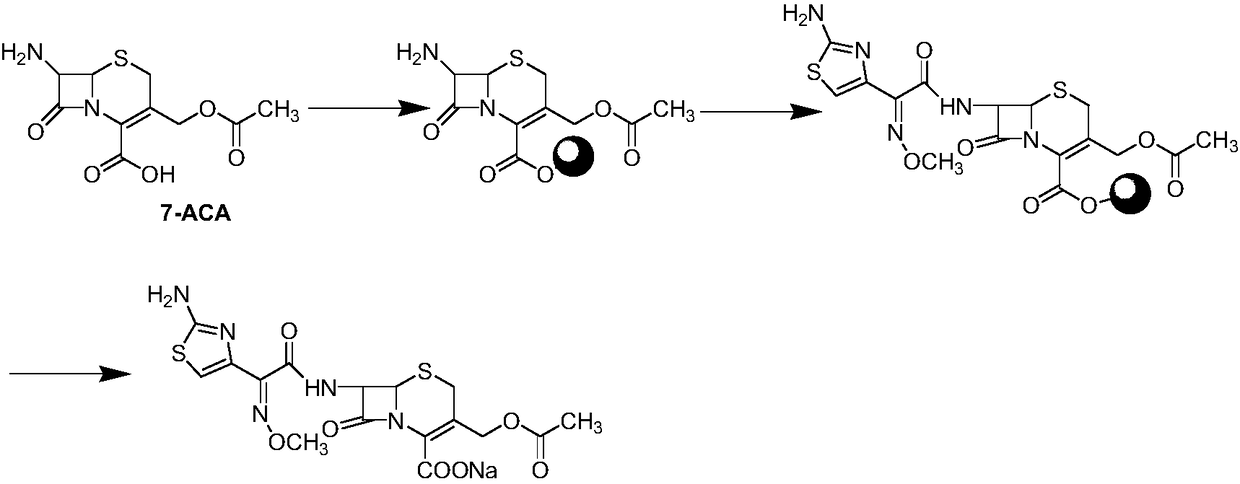

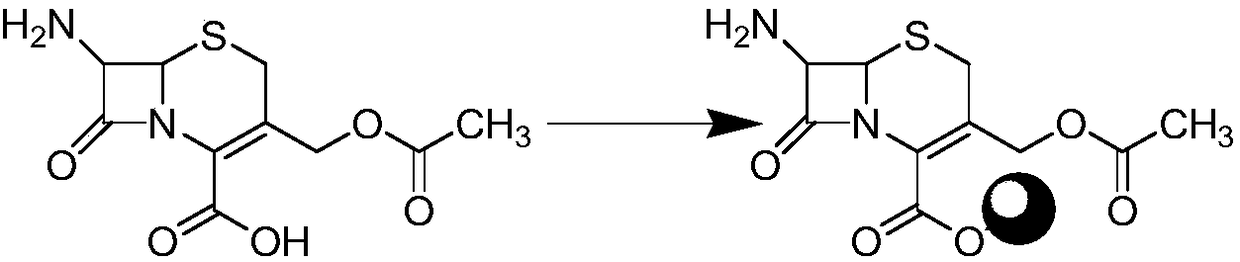

[0017] Example 1: Bridging of 7-ACA and solid phase carrier

[0018]

[0019] In the glazed glass column, react 25g 7-ACA and chloromethyl resin in 100ml DMF, make it fully bridged with the solid-phase carrier, use N after the end of the reaction Flow to remove the solvent, wash the resin with dichloromethane and pyridine, Proceed directly to the next reaction.

Embodiment 2

[0020] Embodiment two: prepare the cefotaxime of solid phase bridging

[0021]

[0022] In a glazed glass column, then add dichloromethane (75ml)-triethylamine (8g) solution in the column, stir under nitrogen protection, add 25g 2-(2-amino-4-thiazolyl)-2 at room temperature -(methoxyimino) thiothiazolyl acetate, react for 6h. After the reaction, the solvent was removed under N2 flow, and the resin was washed with dichloromethane and pyridine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com